Read Sharp AL-1456 (serv.man8) Service Manual online

AL-1555 OPERATIONAL DESCRIPTIONS 7 - 1

[7] OPERATIONAL DESCRIPTIONS

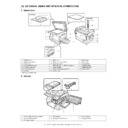

1. Outline of operation

The outline of operation is described referring to the basic configuration.

(Basic configuration)

(Outline of copy operation)

Setting conditions

1) Set copy conditions such as the copy quantity and the copy density

with the operation section, and press the COPY button. The

information on copy conditions is sent to the MCU.

information on copy conditions is sent to the MCU.

Image scanning

2) When the COPY button is pressed, the scanner section starts

Photo signal/Electric signal conversion

3) The image is converted into electrical signals by the CCD circuit

and passed to the MCU.

Image process

under the revised conditions and sent to the LSU (laser unit) as

print data.

print data.

Electric signal/Photo signal (laser beam) conversion

5) The LSU emits laser beams according to the print data.

(Electrical signals are converted into photo signals.)

6) The laser beams are radiated through the polygon mirror and

various lenses to the OPC drum.

Printing

7) Electrostatic latent images are formed on the OPC drum according

to the laser beams, and the latent images are developed to be

visible images(toner images).

visible images(toner images).

8) Meanwhile the paper is fed to the image transfer section in

synchronization with the image lead edge.

9) After the transfer of toner images onto the paper, the toner images

are fused to the paper by the fusing section. The copied paper is

discharged onto the exit tray.

discharged onto the exit tray.

(Outline of printer operation)

The print data sent from the PC are passed through the I/F and the

MCU to the LSU. The procedures after that are the same as above 5)

and later.

MCU to the LSU. The procedures after that are the same as above 5)

and later.

(Outline of scanner operation)

The scan data are passed through the MCU and the I/F to the PC

according to the conditions requested by the PC or set by the opera-

tions with the operation panel.

according to the conditions requested by the PC or set by the opera-

tions with the operation panel.

Operation

section

Scanner section

CCD

MCU (Main control/image process section)

Printer/

Scanner I/F

Scanner I/F

USB or Parallel

PC

Note: The scanner function is effective

only by USB connection.

Laser beam

Paper exit

Fusing section

Paper transport section

Manual paper

feed section

Cassette paper

feed section

Printer section

LSU (Laser unit)

Laser diode, Polygon mirror lens

Laser diode, Polygon mirror lens

Process section

AL-1555 OPERATIONAL DESCRIPTIONS 7 - 2

2. Scanner section

A. Scanner unit

The scanner unit in the digital copier scans images.

It is composed of the optical unit and the drive unit. The optical unit

performs scanning in the main scan direction with the light receiving

elements (color CCD). The drive unit performs scanning in the sub

scanning direction by moving the optical unit.

performs scanning in the main scan direction with the light receiving

elements (color CCD). The drive unit performs scanning in the sub

scanning direction by moving the optical unit.

B. Optical system

Two white lamps are used as the light source.

Light radiated from the light source is applied to the document on the

document table. The reflected light from the document is reflected 5

times by No. 1 - No. 3 mirrors and passed through the reduction lens to

form images on the light-receiving surface of 3-line CCD.

document table. The reflected light from the document is reflected 5

times by No. 1 - No. 3 mirrors and passed through the reduction lens to

form images on the light-receiving surface of 3-line CCD.

The light-receiving surface of the color CCD is provided with 3 line

scanning sections for RGB. Separate images scanned in each color

section are overlapped to complete color scanning. (When PC scan-

ning)

scanning sections for RGB. Separate images scanned in each color

section are overlapped to complete color scanning. (When PC scan-

ning)

The resolution is 600dpi.

When copying, only the green component is used to print with the

printer.

printer.

The color component for printing can be switched to red or blue by the

service simulation.

service simulation.

(Spectrum characteristics of the lamp)

(Spectrum characteristics of the color CCD)

(Optical unit)

C. Drive system

The drive system is composed of the scanner motor, the pulley gear,

the idle pulley, the idle gear, the belt 473, the belt 190, and the shaft.

the idle pulley, the idle gear, the belt 473, the belt 190, and the shaft.

The motor rotation is converted into reciprocated movements of the

belt 473 through the idle gear, the pulley gear, the belt 190, and the

idle pulley to drive the optical unit.

belt 473 through the idle gear, the pulley gear, the belt 190, and the

idle pulley to drive the optical unit.

MBVM26W25W260NLH/G

0.00E+00

1.00E-01

2.00E-01

3.00E-01

4.00E-01

5.00E-01

6.00E-01

0

200

400

600

800

Wave length (nm)

Intensity of UV

Lamp : MBVM26W25W260NLH/G

Lamp current : 5mA

Temp. : 25 degree

Lamp current : 5mA

Temp. : 25 degree

1

Table glass

2

Optical unit

3

Lens

4

Mirror 1

5

Mirror 2

6

Mirror 3

7

CCD PWB

8

Lamp

9

Reflector

1

9

8

10

8

9

7

3

5

4

2

6

1

Scanner motor

2

Pulley gear

3

Idle pulley

4

Belt 473

5

Belt 190

6

Optical unit

7

Shaft

8

Idle gear

9

7

3

4

6

2

8

5

1

3

AL-1555 OPERATIONAL DESCRIPTIONS 7 - 3

3. Laser unit

The image data sent from the MCU (image process circuit) is sent to

the LSU (laser unit), where it is converted into laser beams.

the LSU (laser unit), where it is converted into laser beams.

A. Basic structure

The LSU unit is the writing section of the digital optical system.

The semiconductor laser is used as the light source, and images are

formed on the OPC drum by the polygon mirror and f

formed on the OPC drum by the polygon mirror and f

θ

lens, etc.

The laser beams are passed through the collimator lens, the cylindrical

lens, the polygon mirror, the f

lens, the polygon mirror, the f

θ

lens, and the mirror to form images on

the OPC drum in the main scanning direction. The laser emitting PWB

is provided with the APC (auto power control) in order to eliminate fluc-

tuations in the laser power. The BD PWB works for measurement of

the laser writing start point.

is provided with the APC (auto power control) in order to eliminate fluc-

tuations in the laser power. The BD PWB works for measurement of

the laser writing start point.

Makes the laser scanning speeds at both ends of the drum same as

each other.

each other.

B. Laser beam path

C. Composition

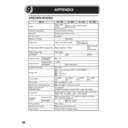

Effective scanning width: 216mm (max.)

Resolution: 600dpi

Beam diameter: 75um in the main scanning direction, 80um in the sub

scanning direction

scanning direction

Image surface power: 0.17 ±0.01mW (Laser wavelength 770 - 795nm)

Polygon motor section: Brushless motor 20.787rpm

No. of mirror surfaces: 6 surfaces

No. of mirror surfaces: 6 surfaces

4. Fuser section

No

Component

Function

1

Semiconductor laser

Generates laser beams.

2

Collimator lens

Converges laser beams in parallel.

3

Polygon mirror,

polygon motor

polygon motor

Reflects laser beams at a constant rpm.

4

BD (Mirror, lens, PWB) Detects start timing of laser scanning.

5

f

θ

lens

Converges laser beams at a spot on the

drum.

drum.

Makes the laser scanning speeds at both

ends of the drum same as each other.

(Refer to the figure below.)

ends of the drum same as each other.

(Refer to the figure below.)

1

2

3

4

5

a

≠

b

≠

c

a

b

c

d = e = f

d

e

f

f

θ

LENS

AL-1555 OPERATIONAL DESCRIPTIONS 7 - 4

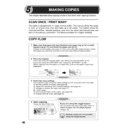

A. General description

General block diagram (cross section)

Top view

(1) Heat roller

A Teflon roller is used for the heat roller and a silicone rubber roller is

used for the lower heat roller for better toner fusing performance and

paper separation.

used for the lower heat roller for better toner fusing performance and

paper separation.

(2) Separator pawl

Three separator pawls are used on the upper heat roller. The separa-

tor pawls are Teflon coated to reduce friction with the roller and prevent

a smear on the paper caused by the separator pawl.

tor pawls are Teflon coated to reduce friction with the roller and prevent

a smear on the paper caused by the separator pawl.

(3) Thermal control

1) The heater lamp, thermistor, main PWB, DC power supply PWB,

and triac within the power supply unit are used to control the

temperature in the fuser unit.

To prevent against abnormally high temperature in the fuser unit, a

thermal breaker and thermal fuse are used for safety purposes.

temperature in the fuser unit.

To prevent against abnormally high temperature in the fuser unit, a

thermal breaker and thermal fuse are used for safety purposes.

2) The surface temperature of the upper heat roller is set to 165 -

190°C. The surface temperature during the power save mode is

set to 100°C.

set to 100°C.

3) The self-check function comes active when one of the following

malfunctions occurs, and an "H" is displayed on the multicopy

window.

window.

a. When the heat roller surface temperature rises above 240°C.

b. When the heat roller surface temperature drops below 100°C during

the copy cycle.

c. Open thermistor

d. Open thermal fuse

e. When the heat roller temperature does not reach 190°C within 27

second after supplying the power.

(4) Fusing resistor

Fusing resistor

This model is provided with a fusing resistor in the fusing section to

improve transfer efficiency.

improve transfer efficiency.

Since the upper heat roller is conductive, when using copy paper that

contains moisture and the distance between the transfer unit and the

fusing unit is short, the transfer current may find a path to ground via

the copy paper, the upper heat roller and the discharging brush.

contains moisture and the distance between the transfer unit and the

fusing unit is short, the transfer current may find a path to ground via

the copy paper, the upper heat roller and the discharging brush.

5. Paper feed section and paper transport

section

A. Paper transport path and general operations

Paper feed is made in two ways; the tray paper feed and the manual

paper feed. The tray is of universal-type, and has the capacity of 250

sheets.

paper feed. The tray is of universal-type, and has the capacity of 250

sheets.

The front loading system allows you to install or remove the tray from

the front cabinet.

the front cabinet.

The general descriptions on the tray paper feed and the manual paper

feed operation are given below.

feed operation are given below.

Separator pawl

PPD2

Thermal fuse

Thermistor

Heat roller

Paper guide

Pressure roller

Heat roller

Thermistor

Thermal fuse

Heater lamp

Separator pawl

Safety device

(thermal breaker, thermal

fuse)

(thermal breaker, thermal

fuse)

Triac (in the

power supply unit)

power supply unit)

Heated by the heater

lamp. (950W)

The surface temperature

of the upper heat roller is

sensed by the thermistor.

of the upper heat roller is

sensed by the thermistor.

Level of the thermistor is

controlled by the main PWB.

controlled by the main PWB.

With the signal from the

main PWB, the triac is

controlled on and off.

(power supply PWB)

main PWB, the triac is

controlled on and off.

(power supply PWB)

1

Scanner unit

8

Drum

2

Copy lamp

9

Transfer unit

3

LSU (Laser unit)

10

Pickup roller

4

Paper exit roller

11

Manual paper feed tray

5

Main charger

12

Manual paper feed roller

6

Heat roller

13

PS roller unit

7

Pressure roller

14

Paper feed roller

1

5

4

3

7

6

8

9

11

12

13

14

10

2