Read Sharp AL-1456 (serv.man7) Service Manual online

AL-1555 COPY PROCESS 6 - 1

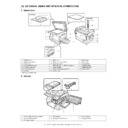

[6] COPY PROCESS

1. Functional diagram

(Basic operation cycle)

(20 microns thick)

Aluminum drum

Pigment layer (0.2

to 0.3 microns thick)

to 0.3 microns thick)

An OPC drum is used for the photoconductor.

(Structure of the OPC drum layers)

(Structure of the OPC drum layers)

OPC layer

Main charger

Laser beam

MG roller

Cleaning blade

Drum

Transfer unit

Resist roller

Exposure

Main high voltage unit

Saw tooth

Charge

Drum

Cleaning

Cleaning blade

Waste toner box

Paper release

Fusing

Separation

Heat roller

Heater lamp

Transfer

Transfer charger

Transfer high

voltage unit

voltage unit

Developing

Toner

Developer

Print process

Paper transport route

Semiconductor laser

Manual feed

PS roller

Focus correction lens

Electrode

Synchronization

with drum

Cassette

paper feed

To face

down tray

down tray

AL-1555 COPY PROCESS 6 - 2

2. Outline of print process

This printer is a non-impact printer that uses a semiconductor laser

and electrostatic print process. This printer uses an OPC (Organic

Photo Conductor) for its photoconductive material.

Photo Conductor) for its photoconductive material.

First, voltage from the main corona unit charges the drum surface and

a latent image is formed on the drum surface using a laser beam. This

latent image forms a visible image on the drum surface when toner is

latent image forms a visible image on the drum surface when toner is

applied. The toner image is then transferred onto the print paper by the

transfer corona and fused on the print paper in the fusing section with

a combination of heat and pressure.

a combination of heat and pressure.

Step-1: Charge

Step-2: Exposure

Step-2: Exposure

*

Latent image is formed on the drum.

Step-3: Developing

Latent image formed on the drum is then changed into visible

image with toner.

Step-4: Transfer

The visible image (toner image) on the drum is transferred

onto the print paper.

Step-5: Cleaning

Residual toner on the drum surface is removed and collected

by the cleaning blade.

Step-6: Optical discharge

Residual charge on the drum surface is removed, by

semiconductor laser beam.

3. Actual print process

Step-1: DC charge

A uniform negative charge is applied over the OPC drum surface by

the main charging unit. Stable potential is maintained by means of the

Scorotron charger.

Scorotron charger.

Positive charges are generated in the aluminum layer.

Step-2: Exposure (laser beam, lens)

A Laser beam is generated from the semiconductor laser and

controlled by the print pattern signal. The laser writes onto the OPC

controlled by the print pattern signal. The laser writes onto the OPC

drum surface through the polygon mirrors and lens. The resistance of

the OPC layer decreases for an area exposed by the laser beam

(corresponding to the print pattern signal). The beam neutralizes the

(corresponding to the print pattern signal). The beam neutralizes the

negative charge. An electrostatic latent image is formed on the drum

surface.

About

DC5.5KV

( 580V/ 390V)

OPC layer

Pigment

layer

layer

Aluminum

drum

drum

OPC layer

Pigment

layer

layer

Aluminum

layer

layer

Drum surface charge

after the exposure

after the exposure

Non-image area

Image area

Semiconductor laser

Exposure

(semiconductor laser)

(semiconductor laser)

AL-1555 COPY PROCESS 6 - 3

Step-3: Developing (DC bias)

A bias potential is applied to the MG roller in the two component

magnetic brush developing method, and the toner is charged negative

magnetic brush developing method, and the toner is charged negative

through friction with the carrier.

Non-image area of the drum surface charged with negative potential

repel the toner, whereas the laser exposed portions where no negative

repel the toner, whereas the laser exposed portions where no negative

charges exist, attract the toner. As a result, a visible image appears on

the drum surface.

Toner is attracted over the shadowed area because of the developing

bias.

Step-4: Transfer

The visible image on the drum surface is transferred onto the print

paper by applying a positive charge from the transfer corona to the

paper by applying a positive charge from the transfer corona to the

backside of the print paper.

Step-5: Separation

Since the print paper is charged positively by the transfer corona, it is

discharged by the separation corona. The separation corona is

connected to ground.

connected to ground.

Step-6: Cleaning

Toner remaining on the drum is removed and collected by the cleaning

blade. It is transported to the waste toner collecting section in the

blade. It is transported to the waste toner collecting section in the

cleaning unit by the waste toner transport roller.

S

N

N

:Carrier (Magnetized particle)

:Toner (Charge negative by friction)

(N) (S) Permanent magnet

:Toner (Charge negative by friction)

(N) (S) Permanent magnet

(provided in three locations)

MG roller

DC

400V 8V

About DC 5.2kV

AL-1555 COPY PROCESS 6 - 4

Step-7: Optical discharge (Semiconductor laser)

Before the drum rotation is stopped, the semiconductor laser is

radiated onto the drum to reduce the electrical resistance in the OPC

radiated onto the drum to reduce the electrical resistance in the OPC

layer and eliminate residual charge, providing a uniform state to the

drum surface for the next page to be printed.

When the electrical resistance is reduced, positive charges on the

When the electrical resistance is reduced, positive charges on the

aluminum layer are moved and neutralized with negative charges on

the OPC layer.

Charge by the Scorotron charger

Function

The Scorotron charger functions to maintain uniform surface potential

on the drum at all times, It control the surface potential regardless of

on the drum at all times, It control the surface potential regardless of

the charge characteristics of the photoconductor.

Basic function

A screen grid is placed between the saw tooth and the

photoconductor. A stable voltage is added to the screen grid to

maintain the corona current on the photoconductor.

As the photoconductor is charged by the saw tooth from the main

As the photoconductor is charged by the saw tooth from the main

corona unit, the surface potential increases. This increases the current

flowing through the screen grid. When the photoconductor potential

nears the grid potential, the current turns to flow to the grid so that the

nears the grid potential, the current turns to flow to the grid so that the

photoconductor potential can be maintained at a stable level.

Process controlling

Function

The print pattern signal is converted into an invisible image by the

semiconductor laser using negative to positive (reversible) developing

semiconductor laser using negative to positive (reversible) developing

method. Therefore, if the developing bias is added before the drum is

charged, toner is attracted onto the drum. If the developing bias is not

added when the drum is charged, the carrier is attracted to the drum

added when the drum is charged, the carrier is attracted to the drum

because of the strong electrostatic force of the drum.

To avoid this, the process is controlled by adjusting the drum potential

and the grid potential of the Scorotron charger.

and the grid potential of the Scorotron charger.

Basic function

Voltage added to the screen grid can be selected, high and low. To

make it easily understood, the figure below shows voltage transition at

make it easily understood, the figure below shows voltage transition at

the developer unit.

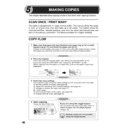

Start

1) Because the grid potential is at a low level, the drum potential is at

about -400V. (Carrier may not be attracted though the carrier is

pulled towards the drum by the electrostatic force of -400V.

pulled towards the drum by the electrostatic force of -400V.

2) Developing bias (-400V) is applied when the photoconductor

potential is switched from LOW to HIGH.

3) Once developing bias (-400V) is applied and the photo conductor

potential rises to HIGH, toner will not be attracted to the drum.

Stop

The reverse sequence takes place.

Retaining developing bias at an abnormal occurrence

Retaining developing bias at an abnormal occurrence

Function

The developing bias will be lost if the power supply was removed

during print process. In this event, the drum potential slightly abates

during print process. In this event, the drum potential slightly abates

and the carrier makes deposits on the drum because of strong static

power. To prevent this, the machine incorporates a function to retain

the developing bias for a certain period and decrease the voltage

the developing bias for a certain period and decrease the voltage

gradually against possible power loss.

Basic function

Normally, the developing bias voltage is retained for a certain time

before the drum comes to a complete stop if the machine should stop

before completing the normal print cycle. The developing bias can be

added before resuming the operation after an abnormal interruption.

added before resuming the operation after an abnormal interruption.

Therefore, carrier will not make a deposit on the drum surface.

Semiconductor laser

0

START

STOP

Print potential

Toner attract

potential

potential

2)

3)

1)

Low

4)

High

Drum potential

Developing bias

Time