|

MX-M950 MX-MM1100 (serv.man6)

Virtual Manual

Service Manual

|

|

10.96 MB

|

|

MX-M950 MX-MM1100 (serv.man7)

Installation Manuals for Peripherals

Service Manual

|

|

6.67 MB

|

|

|

MX-M950 MX-MM1100 (serv.man8)

Details of each Section - M Waste Toner Section

Service Manual

|

3

|

809.92 KB

|

|

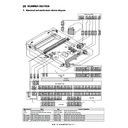

MX-M950 MX-MM1100 (serv.man9)

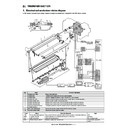

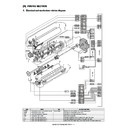

Main Machine

Service Manual

|

|

16.67 MB

|

|

|

MX-M950 MX-MM1100 (serv.man10)

Circuit Diagram

Service Manual

|

127

|

13.33 MB

|

|

MX-M950 MX-MM1100 (serv.man11)

Finishers Hole Punch Units

Service Manual

|

|

27.9 MB

|

|

MX-M950 MX-MM1100 (serv.man12)

Paper Feed Units

Service Manual

|

|

11.24 MB

|

|

|

MX-M950 MX-MM1100 (serv.man13)

Details of Each Section - A External Outfit Section

Service Manual

|

4

|

1.49 MB

|

|

|

MX-M950 MX-MM1100 (serv.man14)

Details of Each Section - B Operation Panel

Service Manual

|

4

|

931.66 KB

|

|

|

MX-M950 MX-MM1100 (serv.man15)

Details of Each Section - C DSPF Section

Service Manual

|

27

|

7.66 MB

|

|

|

MX-M950 MX-MM1100 (serv.man16)

Details of Each Section - D Scanner Section

Service Manual

|

10

|

3.01 MB

|

|

|

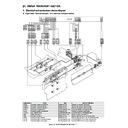

MX-M950 MX-MM1100 (serv.man17)

Details of Each Section - E Tray Paper Feed Section

Service Manual

|

16

|

3.92 MB

|

|

|

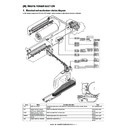

MX-M950 MX-MM1100 (serv.man18)

Details of Each Section - F Paper Transport Section

Service Manual

|

15

|

3.89 MB

|

|

|

MX-M950 MX-MM1100 (serv.man19)

Details of Each Section - G LSU Section

Service Manual

|

4

|

895.21 KB

|

|

|

MX-M950 MX-MM1100 (serv.man21)

Details of Each Section - I Photoconductor Section

Service Manual

|

13

|

3.63 MB

|

|

|

MX-M950 MX-MM1100 (serv.man22)

Details of Each Section - J Toner Supply Section

Service Manual

|

7

|

2.14 MB

|

|

|

MX-M950 MX-MM1100 (serv.man23)

Details of Each Section - K Developing Section

Service Manual

|

3

|

1.12 MB

|

|

|

MX-M950 MX-MM1100 (serv.man24)

Details of Each Section - L Transfer Section

Service Manual

|

5

|

1.54 MB

|

|

|

MX-M950 MX-MM1100 (serv.man25)

Details of Each Section - N Fusing Section

Service Manual

|

7

|

2.01 MB

|

|

|

MX-M950 MX-MM1100 (serv.man26)

Details of Each Section - O ADU Paper Exit Section

Service Manual

|

12

|

4.41 MB

|

|

|

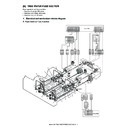

MX-M950 MX-MM1100 (serv.man27)

Details of Each Section - P Drive Section

Service Manual

|

8

|

3.93 MB

|

|

|

MX-M950 MX-MM1100 (serv.man28)

Details of Each Section - Q PWB Section

Service Manual

|

6

|

2.16 MB

|

|

|

MX-M950 MX-MM1100 (serv.man29)

Details of Each Section - R Fan Filter Section

Service Manual

|

7

|

2.03 MB

|

|

|

MX-M950 MX-MM1100 (serv.man30)

Details of Each Section - S Sensor Switch Section

Service Manual

|

3

|

923.53 KB

|

|

|

MX-M950 MX-MM1100 (serv.man31)

Front Back Covers

Service Manual

|

6

|

984.74 KB

|

|

|

MX-M950 MX-MM1100 (serv.man32)

Note For Servicing

Service Manual

|

2

|

557.83 KB

|

|

|

MX-M950 MX-MM1100 (serv.man33)

Section 1 Product Outline

Service Manual

|

4

|

687.19 KB

|

|

|

MX-M950 MX-MM1100 (serv.man34)

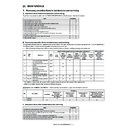

Section 2 Specifications

Service Manual

|

10

|

1.65 MB

|

|

|

MX-M950 MX-MM1100 (serv.man35)

Section 3 Consumable Parts

Service Manual

|

5

|

518.51 KB

|

|

|

MX-M950 MX-MM1100 (serv.man36)

Section 5 External View Intrenal Structure

Service Manual

|

22

|

1.58 MB

|

|

|

MX-M950 MX-MM1100 (serv.man37)

Section 6 Adjustments

Service Manual

|

82

|

10 MB

|

|

|

MX-M950 MX-MM1100 (serv.man38)

Section 7 Simulation

Service Manual

|

103

|

1.17 MB

|

|

|

MX-M950 MX-MM1100 (serv.man39)

Section 8 Self Diagnostics Trouble Codes

Service Manual

|

33

|

770.78 KB

|

|

|

MX-M950 MX-MM1100 (serv.man40)

Section 9 Maintenance

Service Manual

|

86

|

27.14 MB

|

|

|

MX-M950 MX-MM1100 (serv.man41)

Section 10 Rom Version Up

Service Manual

|

3

|

892.26 KB

|

|

|

MX-M950 MX-MM1100 (serv.man42)

Section 11 Electrical

Service Manual

|

56

|

3.89 MB

|

|

|

MX-M950 MX-MM1100 (serv.man43)

Section 12 Others

Service Manual

|

18

|

1.67 MB

|

|

MX-M950 MX-MM1100 (serv.man44)

Peripherals (All)

Service Manual

|

|

28.17 MB

|

|

|

MX-M950 MX-MM1100 (serv.man49)

Guide to Booklet Making

User Guide / Operation Manual

|

38

|

1.76 MB

|

|

|

MX-M950 MX-MM1100 (serv.man50)

User Manual

User Guide / Operation Manual

|

96

|

2.14 MB

|

|

MX-M950 MX-MM1100 (serv.man114)

EFI PCL Print Driver. Windows XP

Drivers

|

|

5.12 MB

|

|

MX-M950 MX-MM1100 (serv.man115)

EFI Postscript Print Driver. Windows XP

Drivers

|

|

4.75 MB

|

|

|

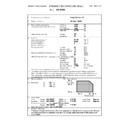

MX-M950 MX-MM1100 (serv.man45)

Parts Guide (Revised December 2016).

Parts Guide

|

127

|

27.48 MB

|

|

|

MX-M950 MX-MM1100 (serv.man46)

MFX1 (Multi Bypass Tray)

Parts Guide

|

15

|

1.69 MB

|

|

|

MX-M950 MX-MM1100 (serv.man47)

FDX1 (Folding Unit)

Parts Guide

|

34

|

6.16 MB

|

|

|

MX-M950 MX-MM1100 (serv.man48)

MFX2 (Multi Bypass Tray)

Parts Guide

|

14

|

1.5 MB

|

|

|

MX-M950 MX-MM1100 (serv.man5)

Sharp Media Guide

Specification

|

54

|

2.6 MB

|

|

|

MX-M950 MX-MM1100 (serv.man66)

Parts change for productivity improvement.

Technical Bulletin

|

3

|

184.15 KB

|

|

MX-M950 MX-MM1100 (serv.man67)

MFX1 - DESIGN CHANGE OF MF TRAY 2 UPPER

Technical Bulletin

|

|

143.26 KB

|

|

|

MX-M950 MX-MM1100 (serv.man68)

Enhancement of LC13 Main Drive Gear

Technical Bulletin

|

3

|

760.63 KB

|

|

|

MX-M950 MX-MM1100 (serv.man69)

MFX1 Parts Change

Technical Bulletin

|

2

|

674.63 KB

|

|

|

MX-M950 MX-MM1100 (serv.man70)

Starting Powder List (This list takes priority over information in Service Manuals).

Technical Bulletin

|

4

|

66.25 KB

|

|

|

MX-M950 MX-MM1100 (serv.man71)

NEWLY-REGISTERED SERVICE PARTS FOR FINISHERS

Technical Bulletin

|

5

|

931.93 KB

|

|

|

MX-M950 MX-MM1100 (serv.man72)

Recommended shutdown procedure and Power Cycling of MFD

Technical Bulletin

|

1

|

186.43 KB

|

|

|

MX-M950 MX-MM1100 (serv.man73)

IMPORTANT Handling of EEPROM's.

Technical Bulletin

|

5

|

203.32 KB

|

|

|

MX-M950 MX-MM1100 (serv.man74)

Change of mounting screw for exhaust duct reinforce plate

Technical Bulletin

|

2

|

443.61 KB

|

|

|

MX-M950 MX-MM1100 (serv.man75)

Change of shape of the polygon motor in the LSU

Technical Bulletin

|

2

|

123.26 KB

|

|

|

MX-M950 MX-MM1100 (serv.man76)

Change in the packing of the developer.

Technical Bulletin

|

1

|

45.62 KB

|

|

|

MX-M950 MX-MM1100 (serv.man77)

Paper Jams (FDSBD_NA, ETC.) caused by fusing read torque limiter slipping.

Technical Bulletin

|

2

|

52.32 KB

|

|

|

MX-M950 MX-MM1100 (serv.man78)

Rom Upgrade (11)

Technical Bulletin

|

1

|

17.87 KB

|

|

|

MX-M950 MX-MM1100 (serv.man79)

FIX TO INCREASE THE MARGIN THAT THE FAN MOTOR FASTENER WILL NOT BECOME STRIPPED

Technical Bulletin

|

2

|

41.49 KB

|

|

|

MX-M950 MX-MM1100 (serv.man80)

Improvements to dust resistance of the DSPF scanner

Technical Bulletin

|

4

|

319.04 KB

|

|

|

MX-M950 MX-MM1100 (serv.man81)

PRECAUTIONS WHEN INSERTING A TONER CARTRIDGE

Technical Bulletin

|

1

|

15.47 KB

|

|

|

MX-M950 MX-MM1100 (serv.man82)

F1-09, F1-11 and BLTJAM Codes

Technical Bulletin

|

1

|

86.3 KB

|

|

|

MX-M950 MX-MM1100 (serv.man83)

Rom Update (9) To (10)

Technical Bulletin

|

4

|

27.79 KB

|

|

|

MX-M950 MX-MM1100 (serv.man84)

ISSUING EXPLANATORY MATERIAL OF JOB LOG CODES.

Technical Bulletin

|

13

|

160.14 KB

|

|

|

MX-M950 MX-MM1100 (serv.man85)

Adhesion of dirt on drum separator pawl transtering to the paper edge

Technical Bulletin

|

1

|

30.14 KB

|

|

|

MX-M950 MX-MM1100 (serv.man86)

POIND_N Jams due to paper sticking to the OPC drum

Technical Bulletin

|

1

|

47.23 KB

|

|

|

MX-M950 MX-MM1100 (serv.man87)

CHANGE OF INITIAL VALUES OF PREHEAT MODE AND AUTO POWER SHUT-OFF MODE OF ENERGY STAR VER1.1

Technical Bulletin

|

2

|

20.01 KB

|

|

|

MX-M950 MX-MM1100 (serv.man88)

Rom Upgrade (8)

Technical Bulletin

|

3

|

25.99 KB

|

|

|

MX-M950 MX-MM1100 (serv.man89)

PAPER FEED JAMS (DPFD1_N4, ETC.)

Technical Bulletin

|

2

|

55.54 KB

|

|

|

MX-M950 MX-MM1100 (serv.man90)

Intermittent background on copies or prints

Technical Bulletin

|

1

|

1.04 MB

|

|

|

MX-M950 MX-MM1100 (serv.man91)

Rom Update (7)

Technical Bulletin

|

2

|

22.88 KB

|

|

|

MX-M950 MX-MM1100 (serv.man92)

Service parts for the draw connectors mounted on the ADU and on the machine frame.

Technical Bulletin

|

2

|

61.59 KB

|

|

|

MX-M950 MX-MM1100 (serv.man93)

REF 25 Special Firmware Update For changes to Pamphlet mode, Z Folding mode Page inserts Please read carefully before installing Firmware

Technical Bulletin

|

4

|

149.52 KB

|

|

|

MX-M950 MX-MM1100 (serv.man94)

Rustproof paper guide for the ADU paper exit unit

Technical Bulletin

|

2

|

37.08 KB

|

|

|

MX-M950 MX-MM1100 (serv.man95)

REF 23 -Countermeasures for preventing breakages of the drawer connectors of the ADU exit unit.

Technical Bulletin

|

2

|

64.17 KB

|

|

|

MX-M950 MX-MM1100 (serv.man96)

Preventing the malfunction of the operation panel.

Technical Bulletin

|

2

|

137.64 KB

|

|

|

MX-M950 MX-MM1100 (serv.man97)

Reducing uneven charge (image steaking)

Technical Bulletin

|

2

|

20.51 KB

|

|

|

MX-M950 MX-MM1100 (serv.man98)

Countermeasures taken when toner is not supplied due to disconnection of toner hopper unit harness - (F2-02 Error code)

Technical Bulletin

|

3

|

159.48 KB

|

|

|

MX-M950 MX-MM1100 (serv.man99)

HDD Replacment

Technical Bulletin

|

5

|

94.47 KB

|

|

|

MX-M950 MX-MM1100 (serv.man100)

ROM UPGRADE 0200H0

Technical Bulletin

|

2

|

19.39 KB

|

|

|

MX-M950 MX-MM1100 (serv.man101)

ICU 0110H0

Technical Bulletin

|

3

|

18.46 KB

|

|

|

MX-M950 MX-MM1100 (serv.man102)

REF 014 Improvement in irregular print image at an irregular pitch

Technical Bulletin

|

2

|

56.54 KB

|

|

|

MX-M950 MX-MM1100 (serv.man103)

REF 011 Transfer roller bearing added to the Transfer belt kit (MX-850TT)

Technical Bulletin

|

2

|

23.53 KB

|

|

|

MX-M950 MX-MM1100 (serv.man104)

REF 010 Revision of maintenance manuals

Technical Bulletin

|

1

|

18.2 KB

|

|

|

MX-M950 MX-MM1100 (serv.man105)

REF 009 Revisions to the installation Manual

Technical Bulletin

|

2

|

375.33 KB

|

|

|

MX-M950 MX-MM1100 (serv.man106)

Information about the revisions of the main unit service manual

Technical Bulletin

|

3

|

615.68 KB

|

|

|

MX-M950 MX-MM1100 (serv.man107)

Change of a screw tightening for tray 3 of the main unit

Technical Bulletin

|

3

|

209.24 KB

|

|

|

MX-M950 MX-MM1100 (serv.man108)

Rom Upgrade

Technical Bulletin

|

2

|

16.13 KB

|

|

|

MX-M950 MX-MM1100 (serv.man109)

Consideration Concerning Installation of the MX-FXX1

Technical Bulletin

|

3

|

253.32 KB

|

|

MX-M950 MX-MM1100 (serv.man56)

MXM850 950 1100 Firmware for Equitrac issue. 02.06.H0o_B

Driver / Update

|

|

27.56 MB

|

|

MX-M950 MX-MM1100 (serv.man57)

New Special Firmware Original dated 30.07.08 V1 firmware for 1 sheet pamphlet w o stapling,Combination with punch and z folding Z folding with cover in copy mode to work with Macronix PCU chips

Driver / Update

|

|

27.44 MB

|

|

MX-M950 MX-MM1100 (serv.man58)

Sleep Mode and Under Load

Driver / Update

|

|

27.68 MB

|

|

MX-M950 MX-MM1100 (serv.man59)

SAP Device Types for MX Mono devices.

Driver / Update

|

|

3.18 MB

|

|

MX-M950 MX-MM1100 (serv.man60)

Includes Tech Bulletin

Driver / Update

|

|

27.7 MB

|

|

MX-M950 MX-MM1100 (serv.man61)

ICU 0206H0 - Inc Tech Bulletin

Driver / Update

|

|

27.6 MB

|

|

MX-M950 MX-MM1100 (serv.man62)

Fixed Equitrac Firmware (0206H0c0_B)

Driver / Update

|

|

27.56 MB

|

|

MX-M950 MX-MM1100 (serv.man63)

30.07.08 Special Firmware Update V2. For changes to spec to pamphlet mode, Z Folding when there is a specific need to increase the page insets function. ONLY install when MX-PBX2 is fitted. Read Tech Bulletin 1st

Driver / Update

|

|

27.59 MB

|

|

MX-M950 MX-MM1100 (serv.man64)

Linux PPD for MXM850 950 1100 for use with CUPS.

Driver / Update

|

|

356.95 KB

|

|

MX-M950 MX-MM1100 (serv.man65)

PC Fax Driver (MX-FXX1)

Driver / Update

|

|

17.16 MB

|

|

|

MX-M950 MX-MM1100

EEPROM Programming Procedure

Handy Guide

|

4

|

772.27 KB

|

|

|

MX-M950 MX-MM1100 (serv.man2)

New Configuration and Installation Guide v3.6

Handy Guide

|

21

|

4.88 MB

|

|

|

MX-M950 MX-MM1100 (serv.man3)

39906

Handy Guide

|

21

|

4.31 MB

|

|

|

MX-M950 MX-MM1100 (serv.man4)

May 08

Handy Guide

|

54

|

872.01 KB

|

|

|

MX-M950 MX-MM1100 (serv.man51)

How To Read A Main Machine Serial Number

FAQ

|

1

|

16.5 KB

|

|

|

MX-M950 MX-MM1100 (serv.man52)

Foot space required for all machine and option configuations

FAQ

|

6

|

725.01 KB

|

|

|

MX-M950 MX-MM1100 (serv.man53)

Power Requirments for all Hercules Models

FAQ

|

1

|

190.11 KB

|

|

MX-M950 MX-MM1100 (serv.man54)

PCL PJL PS COMMANDS FOR MXM850 950 1100

FAQ

|

|

84.04 KB

|

|

|

MX-M950 MX-MM1100 (serv.man55)

How to connect MXM850 950 1100 to Linux UNIX systems using CUPS.

FAQ

|

9

|

1.14 MB

|

|

|

MX-M950 MX-MM1100 (serv.man110)

MXM1100

Regulatory Data

|

1

|

39.33 KB

|

|

|

MX-M950 MX-MM1100 (serv.man111)

MXM950

Regulatory Data

|

1

|

39.35 KB

|

|

|

MX-M950 MX-MM1100 (serv.man112)

MX-850GV (Black Developer) MSDS No F-31491

Regulatory Data

|

4

|

296.69 KB

|

|

|

MX-M950 MX-MM1100 (serv.man113)

MX-850GT (Black Toner) MSDS No F-01491

Regulatory Data

|

4

|

36.5 KB

|