Read Sharp AR-FN5 Service Manual online

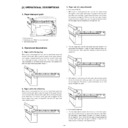

3. Rollers, gates, etc.

No.

Name

Function

1

Paper entry sensor

Detects paper transported from the machine.

2

Transport roller fin

Transports paper in combination with No. 8 roller.

3

Paper entry follower roller (Kick-out

sponge)

sponge)

Transports paper in combination with No. 2 roller.

4

Transport switch gate right

Selects between the escape transport (non-staple mode) and the alignment tray transport (staple

mode).

When selecting the alignment transport (staple mode), this gate drops the rear edge of paper.

mode).

When selecting the alignment transport (staple mode), this gate drops the rear edge of paper.

5

Side guide plate

Aligns paper vertically to the paper transport direction.

6

Upper alignment hold plate

Knocks paper when paper (5th page or later) comes on the alignment tray removing air or adjusting

curls.

curls.

7

Rear edge plate

Aligns paper in the paper transport direction.

8

PS upper roller (Common part)

Transports paper in combination with No. 2, 19, 20 rollers.

9

Paper empty sensor (1A71A)

Detects paper empty on the alignment tray.

10

Shutter

Serves as the paper lead edge reference for alignment of paper, and opens to allow a bundle of

paper to be transported to the paper exit port after stapling.

paper to be transported to the paper exit port after stapling.

11

Transport switch gate left

Selects between the escape tray transport and the offset tray transport.

12

PS upper roller (Common part)

Transports paper in combination with No. 13 roller.

13

Escape transport roller

Transports paper in combination with No. 12 (No. 8) roller.

14

Escape paper exit sensor

Detects paper transport to the escape tray.

15

Transports paper in combination with No. 16 roller.

16

Escape paper exit roller

Transports paper in combination with No. 15 roller.

17

Paper exit roller upper

Transports paper in combination with No. 18 roller. This roller normally follows No. 18 roller. When

discharging a stapled bundle of paper, the electromagnetic clutch turns on to make this roller a drive

roller. The bundle of paper is bent by the difference between this roller speed and the No. 18 roller

speed so that it is not caught by the preceding bundle staple.

discharging a stapled bundle of paper, the electromagnetic clutch turns on to make this roller a drive

roller. The bundle of paper is bent by the difference between this roller speed and the No. 18 roller

speed so that it is not caught by the preceding bundle staple.

18

Paper exit roller lower

Transports (discharges) paper in combination with No. 17 roller.

19

Transport drive roller fin

Transports paper in combination with No. 8 roller.

20

Paper entry roller fin

Transports paper in combination with No. 8 roller.

No.

Part name

Code

Function/Operation

Type

22

Transport switch gate solenoid Left

GLSL

Drive to sort paper into the escape paper exit port and the lift-up tray

paper exit port.

paper exit port.

Solenoid

23

Side guide plate alignment motor

SDM

Aligns paper vertically to the paper transport direction.

Pulse motor

24

Reciprocating alignment motor

BKM

Aligns paper in the paper transport direction.

Pulse motor

25

Paper entry sensor

INPD

Detects paper entry in the finisher and detects JAM. Switch trigger of

the transport switch gate right.

the transport switch gate right.

Photo sensor

26

Paper width sensor

WDPD

Make a distinction between A4 and A5R, LT and INVR. If the paper

entry sensor is ON and this sensor is OFF, it is A5R or INVR.

entry sensor is ON and this sensor is OFF, it is A5R or INVR.

Photo sensor

27

Rear edge plate drive solenoid

BKSLD

Drives the rear edge plate.

Solenoid

28

Rear edge plate home position sensor

BKHP

Detects the home position of the rear edge alignment members.

Photo sensor

29

Tray JAM process detection switch

PGSW

Interlocks when the alignment tray is opened downward in a JAM

process.

process.

Micro switch

1

2

3

20

4

5

6

2

19

7

11

9

10

16

15

14

12

13

17

18

8

8

8