Read Sharp MX-FNX2 (serv.man11) Service Manual online

MX-FNX2/AR-PN1/MX-RBX1 SELF DIAG MESSAGE AND TROUBLE CODE 9 – 8

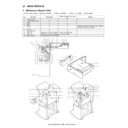

(3) Paper pass (Paper transport section)

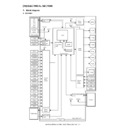

a. The transport motor (FFM) does not operate.

b. A fan motor alarm is generated.

c. A paper jam occurs in the entry port of the interface

transport unit.

transport unit.

Case 1

Cause

Connector pin loose connection

Check &

Remedy

Remedy

Check connection of the connectors.

(CN309, CN307, CN306, CN303, CN301, CN21)

(CN309, CN307, CN306, CN303, CN301, CN21)

Case 2

Cause

Harness disconnection

Check &

Remedy

Remedy

Execute the conduction test between connectors. If

disconnection is found, replace the defective

connectors.

disconnection is found, replace the defective

connectors.

Case 3

Cause

Motor lead breaking

Check &

Remedy

Remedy

Execute the conduction test of coil. If disconnection

is found, replace the coil.

is found, replace the coil.

Case 4

Cause

Control PWB trouble

Check &

Remedy

Remedy

If the motor does not operate in the motor

individual operation mode, replace the control

PWB.

individual operation mode, replace the control

PWB.

Case 1

Cause

Pinching

Check &

Remedy

Remedy

Visually check the suction port and remove foreign

materials.

materials.

Case 2

Cause

Connector pin loose connection

Check &

Remedy

Remedy

Check connection of the connectors.

(CN313, CN307, CN306, CN304, CN301, CN22,

CN23)

(CN313, CN307, CN306, CN304, CN301, CN22,

CN23)

Case 3

Cause

Harness disconnection

Check &

Remedy

Remedy

Execute the conduction test between connectors. If

disconnection is found, replace the defective

connectors.

disconnection is found, replace the defective

connectors.

Case 4

Cause

Motor trouble

Check &

Remedy

Remedy

If the motor does not operate in the motor

individual operation mode, replace the motor.

individual operation mode, replace the motor.

Case 5

Cause

Control PWB trouble

Check &

Remedy

Remedy

If the motor does not operate in the motor

individual operation mode, replace the control

PWB.

individual operation mode, replace the control

PWB.

Case 1

Cause

Flapper solenoid connector pin loose connection

Check &

Remedy

Remedy

Check connection of the connectors.

(CN312, CN307, CN306, CN304, CN301, CN22,

CN23)

(CN312, CN307, CN306, CN304, CN301, CN22,

CN23)

Case 2

Cause

Harness disconnection

Check &

Remedy

Remedy

Execute the conduction test between connectors. If

disconnection is found, replace the defective

connectors.

disconnection is found, replace the defective

connectors.

Case 3

Cause

Flapper solenoid trouble

Check &

Remedy

Remedy

If there is no conduction between CN312 1 pin and

2pin, replace the solenoid.

2pin, replace the solenoid.

Case 4

Cause

Control PWB trouble

Check &

Remedy

Remedy

If the flapper does not operate in the individual

operation mode, replace the control PWB.

operation mode, replace the control PWB.

Case 1

Cause

Paper jam

Check &

Remedy

Remedy

Visually check to remove paper jam.

Cause

Sensor connector pin loose connection

Check &

Remedy

Remedy

Check connection of the connectors.

(CN310, CN311, CN307, CN306, CN304, CN301,

CN22, CN23)

(CN310, CN311, CN307, CN306, CN304, CN301,

CN22, CN23)

Case 2

Cause

Harness disconnection

Check &

Remedy

Remedy

Execute the conduction test between connectors. If

disconnection is found, replace the defective

connectors.

disconnection is found, replace the defective

connectors.

Cause

Sensor trouble

Check &

Remedy

Remedy

Replace the sensor at the paper jam position.

Case 3

Cause

Sensor flag operation trouble

Check &

Remedy

Remedy

Visually check the sensor flag operation. If it is

caught in the operation, replace the sensor flag.

caught in the operation, replace the sensor flag.

Case 4

Cause

Control PWB trouble

Check &

Remedy

Remedy

If the sensor level varies but the phenomenon

remains when each sensor is turned ON/OFF,

replace the control PWB.

remains when each sensor is turned ON/OFF,

replace the control PWB.