Read Sharp MX-FNX2 (serv.man8) Service Manual online

MX-FNX2/AR-PN1/MX-RBX1 DISASSEMBLY AND ASSEMBLY 6 – 1

âºíuÇ´

Service Manual

[6] DISASSEMBLY AND

ASSEMBLY

1)

Turn off the host machine, disconnect the saddle stitch finisher

connctor.

connctor.

2)

Free the lock, and remove the saddle stitch finisher from the

host machine.

host machine.

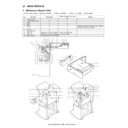

1. Saddle stitch finiser (MX-FNX2)

A. Externals and Controls

(1) Delivery tray

1)

Remove the delivery tray.

(2) Front Cover

1)

Open the front door, and remove the knob.

2)

Remove the front cover.

(3) Rear Cover

1)

Remove the rear cover.

(4) Upper Cover

1)

Remove the front cover. (See (2).)

2)

Remove the rear cover. (See (3).)

3)

Open the upper cover, and remove the cover band.

4)

Detach the processing cover, and remove the upper cover.

1

2

1

2

1

2

MX-FNX2/AR-PN1/MX-RBX1 DISASSEMBLY AND ASSEMBLY 6 – 2

(5) Processing Tray Upper Cover

1)

Remove the front cover. (See (2).)

2)

Remove the rear cover. (See (3).)

3)

Remove the upper cover. (See (4).)

4)

Disconnect the connector [1] and remove the screw [2].

5)

While lifting the processing tray cover [3], disconnect the con-

nector [4], then remove the processing tray upper cover [3].

nector [4], then remove the processing tray upper cover [3].

(6) Upper Right Cover, Middle Right Cover

1)

Remove the front cover. (See (2).)

2)

Remove the rear cover. (See (3).)

3)

Open the upper cover, then remove the upper right cover and

the middle right cover.

the middle right cover.

(7) Removing the Saddle Guide

1)

Remove the delivery tray. (See (1).)

2)

Remove the front cover. (See (2).)

3)

Remove the rear cover. (See (3).)

4)

Free the delivery tray support plate (front) [1] and the delivery

tray support plate (rear) [2] to the outside from the rail grooves.

tray support plate (rear) [2] to the outside from the rail grooves.

5)

Remove the four screws [3].

6)

Shift the side guide [4] lightly to the front, and free the engage-

ment of the paper surface detecting lever (rear) [5]; then,

detach the side guide [4].

ment of the paper surface detecting lever (rear) [5]; then,

detach the side guide [4].

NOTE: Be sure to mount the side guide after securely fitting the

paper surface detecting lever (rear) [5] in the groove of the

paper surface detecting lever (middle) [6].

After completion of mounting, push the paper surface

detecting lever several times to make sure that side guide

is mounted securely.

paper surface detecting lever (middle) [6].

After completion of mounting, push the paper surface

detecting lever several times to make sure that side guide

is mounted securely.

[2]

[1]

[3]

[4]

1

2

[1]

[2]

[3]

[3]

[3]

[3]

[5]

[4]

[6]

[5]

[5]

[6]

MX-FNX2/AR-PN1/MX-RBX1 DISASSEMBLY AND ASSEMBLY 6 – 3

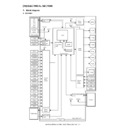

B. Feeding System

(1) Removing the Stapler Unit

1)

Open the front door.

2)

Slide out the stapler unit while pressing the stopper.

NOTE: Do not remove the stapler stapler frame shaft. If removed,

the position where the staple driver (lower unit of the sta-

pler) [4] shoots stables will shift from the position where the

staple clincher (upper unit of the stapler) [5] receives sta-

ples.

pler) [4] shoots stables will shift from the position where the

staple clincher (upper unit of the stapler) [5] receives sta-

ples.

(2) Adjusting the Stapler Phase

When the gears or timing belt at the front of the stapler is replaced

or removed for some reason, the staple shooting timing of the

(lower unit of the stapler) does not match the staple bending timing

of the staple clincher (upper unit of the stapler). Adjust the stapler

phase following the procedure described below.

or removed for some reason, the staple shooting timing of the

(lower unit of the stapler) does not match the staple bending timing

of the staple clincher (upper unit of the stapler). Adjust the stapler

phase following the procedure described below.

1)

Detach the gear cover [2] from the staple driver [1].

2)

Remove the E-ring [3] to detach the side cover [5] of the staple

clincher [4].

clincher [4].

3)

Remove the two E-rings [6] to remove the staple jam releasing

gear [7], timing belt [8], and relay gear 1 [9]. Remove the

spacer and spring at the back of the staple jam releasing gear.

gear [7], timing belt [8], and relay gear 1 [9]. Remove the

spacer and spring at the back of the staple jam releasing gear.

4)

Remove the screw [10] and spring [11] to remove the belt ten-

sioner [12].

sioner [12].

5)

Remove the timing belt [13].

6)

Remove the E-ring [14] to remove the staple position check

gear [15].

gear [15].

7)

Turn the gear [16] to align the round hole in the staple driver

gear with the round hole [17] at the back.

gear with the round hole [17] at the back.

1

2

3

[5]

[4]

Timing belt

Gear

Gear

[2]

[5]

[3]

[4]

[1]

[8]

[10]

[12]

[6]

[7]

[11]

[9]

[14]

[15]

[13]

[16]

[17]

MX-FNX2/AR-PN1/MX-RBX1 DISASSEMBLY AND ASSEMBLY 6 – 4

8)

Insert a pin [18] with a diameter of approximately 2 mm

(use of a 2 mm Allen wrench is recommended) in the round

hole to secure the gear.

(use of a 2 mm Allen wrench is recommended) in the round

hole to secure the gear.

9)

Turn the gear [19] to align the round hole in the staple clincher

cam with the round hole [20] at the back.

cam with the round hole [20] at the back.

10) Insert a pin [21] with a diameter of approximately 2 mm (use of

a 2 mm Allen wrench is recommended) in the round hole to

secure the gear.

secure the gear.

11) With the gears and cam fixed, install the timing belt [22] on

gears [23] and [24].

12) Mount the staple position check gear [27] so that the blue mark

[25] on the staple position check gear is aligned with the round

hole [26] in the frame.

hole [26] in the frame.

The position where the blue mark is aligned with the round

hole is the home position for stapling. If the staple jam cancel

dial is turned for some reason, the home position deviates,

making it impossible to remove the stapler cartridge. If such a

case, the gear can be returned to the home position by check-

ing blue mark position. Therefore, it is necessary to mount the

gear at the correct position.

hole is the home position for stapling. If the staple jam cancel

dial is turned for some reason, the home position deviates,

making it impossible to remove the stapler cartridge. If such a

case, the gear can be returned to the home position by check-

ing blue mark position. Therefore, it is necessary to mount the

gear at the correct position.

13) Remove the pin securing the gear to the cam.

14) Assemble the spring [28], spacer [29], staple jam releasing

14) Assemble the spring [28], spacer [29], staple jam releasing

gear [30], timing belt [31], and relay gear [32] and secure them

with the E-ring [33].

with the E-ring [33].

(3) Adjusting the Phase of the Gear in the Saddle Unit

If the gears at the front of the saddle unit or the paper fold rollers in

the sale unit are replaced or removed for some reason, adjust the

gear phase following the procedure described below.

1)

the sale unit are replaced or removed for some reason, adjust the

gear phase following the procedure described below.

1)

The paper fold rollers [1] and saddle cam [2] must be posi-

tioned as shown below.

tioned as shown below.

[18]

[19]

[20]

[21]

[23]

[24]

[22]

[25]

[26]

[27]

[30]

[33]

[32]

[28]

[29]

[31]

[2]

[1]