Read Sharp AR-M550 (serv.man90) Technical Bulletin online

Sharp Electronics (UK) Ltd., Technical Services Group

Model Name:

AR-M550U/M620U/M700U

Symptom:

Contamination of Fuser Unit and Dirty Copies (After Copying Large Volumes)

Description:

To resolve the ongoing issues with the AR700/701 FU (Fuser Unit), we have

abolished the current Fuser Units above and have released a new Fuser Unit.

The new fusing cleaning method enables the 300K maintenance cycle (250K

for ARM550)

No maintenance is required up to 300K for Normal Operation, we have set-up

an additional kit AR704KC. This is only to be used when the maintenance

cycle will be shorter than expected due to High Toner Coverage, A3 Printing

and Specialised Paper Stocks. The AR703FU (Fuser Unit) will not require

regular 150K maintenance interval like the previous Fuser Units. Please see

following page for KC parts listings.

The level of Fuser Unit differs on the production time, please see below:

Main Units Before Mass Production In July 2006

=

AR700FU

Main Units After Mass Production In August 2006

=

AR701FU

Main Units After Mass Production In April 2007

=

AR703FU

The new AR703FU (Fuser Unit) can only be upgraded; you are unable

to convert an AR700/701FU (Fuser Unit) to an AR703FU (Fuser Unit).

Maintenance kits have been set-up for the new fusing unit (AR703FU). These

can be ordered from September 07 using the following AR703KC (Cleaning

Kit) and AR704KC (Cleaning Sub Roller Kit).

Preventing Smudges On Copy/Print

Sheet Due To Stained Heat Roller

TECHNICAL BULLETIN

Date:

8

th

June 2007

Model:

ARM-550/620/700u

Ref.:

037

Colour:

White

Page:

1 of 6

Sharp Electronics (UK) Ltd., Technical Services Group

The AR703FU (Fuser Unit) is stamped with an identification mark “N” on the

“caution high temperature” label for easy identification

“caution high temperature” label for easy identification

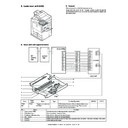

“Mark 1” AR700 FU (Fuser Unit): – CL Plate System GRID

“Mark 2” AR701 FU (Fuser Unit): – CL Roller System is driven by an additional

Drive Frame modification.

“Mark 3” AR703 FU (Fuser Unit): - Slave CL Roller System CL Roller is driven

by the Heat Roller. The additional Drive Frame drives the upper Heat Roller.

“Mark 2” AR701 FU (Fuser Unit): – CL Roller System is driven by an additional

Drive Frame modification.

“Mark 3” AR703 FU (Fuser Unit): - Slave CL Roller System CL Roller is driven

by the Heat Roller. The additional Drive Frame drives the upper Heat Roller.

See diagram below: -

“Mark1”

“Mark 2”

“Mark 3”

The AR703KC kit is not available to order until September 07. If you need to

order the KC kit due to routine maintenance cycles we have put together a

composite parts list utilising the AR700KC kit. Please see next page.

Sharp Electronics (UK) Ltd., Technical Services Group

The AR-704KC kit is not available to order until September 07. This is only to

be used when the maintenance cycle will be shorter than expected due to

High Toner Coverage, A3 Printing and Specialised Paper Stocks. If you need

to order the KC kit due to the above. Please see below composite parts list.

Note 1: - Be sure to upgrade the firmware to the latest version and change

the default values in the following Simulation codes, see below.

Current Firmware: -

Firmware Release Date (October 2005)

Model Name

ROM Control No. MAIN

ROM Control No. MAIN

BOOT

PCU

SCN

F01 Vu4.03.

VM5.32A

V03.10

V02.10

AR-M550U/AR-M620U/AR-M700U

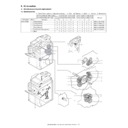

Maintenance kit (AR-704KC) - Not Available Until

Part name

Part code

Qty

Lower CL Roller DG2

NROLM1709FCZZ

1

Lower CL Roller DG2-SP N1

MSPRT3798FCZZ

2

CL Roller bearing

NBRGP0670FCZZ

6

CL Support Roller DG

NROLM1637FCZZ

1

Upper CL Roller N2

NROLN1730FCZZ

1

Lower CL Roller DG2-SP

MSPRT3789FCZZ

2

AR-704KC Kit

"Mark 3"

New fuser systemForward CL roller type

Model Name

ROM Control No. MAIN

ROM Control No. MAIN

BOOT

PCU

SCN

F01 Vn4.03.

VM5.32A

V03.10

V02.10

AR-M550N/AR-M620N/AR-M700N

Maintenance kit (AR-700KC)

Plus these additional parts is equal to

Maintenance kit AR-703KC

(The full AR703 KC kit will be available approx Sept 07)

(The full AR703 KC kit will be available approx Sept 07)

Part name

Part code

Qty

Part name

Part code

Qty

Part name

Part code

Qty Change

Heat CL sheet base

CDAIU0690FC02

1

Lower CL Roller DG2

NROLM1709FCZZ

1

Heat CL sheet base

CDAIU0690FC02

1

No change

Oil roller AS

CROLR1498FC32

1

Lower CL Roller DG2-SP N1

MSPRT3798FCZZ

2

Lower CL Roller DG2

NROLM1709FCZZ

1

Added

Pressure CL plate

LPLTM6430FCZZ

1

CL Roller bearing

NBRGP0670FCZZ

4

CL roller spring

MSPRT3028FCZZ

2

CL Support Roller DG

NROLM1637FCZZ

1

Lower CL Roller DG2-SP N1

MSPRT3798FCZZ

2

Added

CL Roller bearing

NBRGP0670FCZZ

2

Upper CL Roller N2

NROLN1730FCZZ

1

CL Roller bearing

NBRGP0670FCZZ

6

Qty change

Heat roller bearing

NBRGP0700FCZZ

2

Lower CL Roller DG2-SP

MSPRT3789FCZZ

2

Heat roller bearing

NBRGP0700FCZZ

2 No change

Upper heat roller

NROLI1627FCZZ

1

Fusing Paper Feed Upper PG

PGIDM2387FCZZ

1

Upper heat roller

NROLT1452FCZ2

1 No change

Pressure roller

NROLT1452FCZ2

1

Pressure roller

NROLI1627FCZZ

1 No change

Heat roller

NROLT1455FCZ1

1

Heat roller

NROLT1455FCZ1

1 No change

Lower separator pawl

PTME-0283FCZZ

4

Lower separator pawl

PTME-0300FCZZ

6 No change

Upper separator pawl

PTME-0300FCZZ

6

Upper separator pawl

PTME-0283FCZZ

4 No change

CL Support Roller DG

NROLM1637FCZZ

1

Added

Upper CL Roller N2

NROLN1730FCZZ

1

Added

Lower CL Roller DG2-SP

MSPRT3789FCZZ

2

Added

Fusing Paper Feed Upper PG

PGIDM2387FCZZ

1

Added

Previous fusing unit CL plate type

Composite Maintenance Kit For Dragon Fuser (703FU)

+

=

"Mark 1"

"Mark 3"

New fuser system Forward CL roller type

Sharp Electronics (UK) Ltd., Technical Services Group

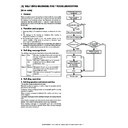

To produce overall improvement in image quality or density, settings of the

following simulation test commands need to be changed.

Without the setting changes made above, excessive density of

Copying/Printing may cause stains on the fusing unit.

Detail Of Modification Of Dragon Fusing Unit: -

Part name

Part code

Qty

Detail of modification (Outline)

1

Flat Screw

LX-BZ0031GCPZ

3

The screw head is changed to flat type, since the screw head may touch the upper

CL roller.

CL roller.

2 Upper CL Plate R

LPLTM7526FCZZ

1 The shape is changed in accordance with the added upper CL roller SP N2.

Upper CL Roller SP N2

MSPRT3806FCZZ

1

Upper CL Roller SP N2

MSPRT3806FCZZ

1

4 Upper CL Plate F

LPLTM7525FCZZ

1 The shape is changed in accordance with the added upper CL roller SP N2.

5 Upper CL Roller N2

NROLN1730FCZZ

1

It is changed from reverse-rotation type to forward-rotation type. (There is no

change in the amount or viscosity of oil or the material or outer diameter of felt.)

change in the amount or viscosity of oil or the material or outer diameter of felt.)

6 CL Roller Bearing

NBRGP0670FCZZ

2

The bearing is changed in accordance with the CL which is changed to the forward-

rotation type.

rotation type.

7 M3x6blue screw

LX-BZ1066FCZZ

1 No change (The screw to attach upper CL plate F)

The parts in the high-lighted cells are included in the package, but they are not attached to the fusing unit.

8 Fusing Paper Feed Upper PG

PGIDM2387FCZZ

1

The paper guide is changed from steel plate type to resin type. (to reduce adhesion

of toner on the paper guide.)

of toner on the paper guide.)

9 Fusing Paper Feed Upper PG fixing plateLPLTM7527FCZZ

1 Added a steel plate to attach the fusing paper feed upper paper uide.

7 M3x6blue screw

LX-BZ1066FCZZ

1 Added screws to attach the two parts above.

10 CL Support Roller DG

NROLM1637FCZZ

1 No change

6 CL Roller Bearing

NBRGP0670FCZZ

2 No change

11 Lower CL roller DG2-SP

MSPRT3789FCZZ

2 The load is changed.

12 Grease JFE552

UKOG-0235FCZZ

2

posi

Grease is applied to the sub heat roller bearing.

Heat CL Sheat Board N AS

CDAIU0690FC02

1 No change

Heat Roller Pressure SP N1

MSPRT3799FCZZ

2 The load is changed.

13 Pressure Lever F DG2

CLEVF0893FC02

1

14 Pressure Lever R DG2

CLEVF0894FC02

1 The shape is changed in accordance with the change in the lower CL roller.

15 Lower CL Roller DG2

NROLM1709FCZZ

1

6 CL Roller Bearing

NBRGP0670FCZZ

2

16 Lower CL Roller DG2-SP N1 MSPRT3798FCZZ

2

The shape is changed in accordance with the change in the lower CL roller.

The load is changed.

The load is changed.

Pressure SP is added to apply pressure to the upper CL roller of forward-rotation type.

3

The shape is changed in accordance with the change in the lower CL roller.

Chnaged from silicone rolelr to metal roller.