Read Sharp CD-XP300 (serv.man10) Service Manual online

CD-XP300H

– 14 –

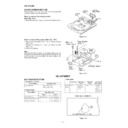

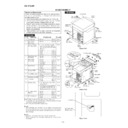

How to remove the pickup (See Fig. 14-2)

1. Remove the stop washer (B1) x 1 pc., to remove the gear

(B2) x 1 pc.

2. Remove the screws (B3) x 2 pcs., to remove the shaft

(B4) x 1 pc.

3. Remove the pickup.

Note

After removing the connector for the optical pickup from the

connector wrap the conductive aluminium foil around the front

end of connector so as to protect the optical pickup from

electrostatic damage.

After removing the connector for the optical pickup from the

connector wrap the conductive aluminium foil around the front

end of connector so as to protect the optical pickup from

electrostatic damage.

Figure 14-2

CD MECHANISM SECTION

Perform steps 1, 2, 3, 10, 11,12 and 13 of the disassembly

method to remove the CD mechanism.

method to remove the CD mechanism.

How to remove the loading motor

(See Fig. 14-1)

(See Fig. 14-1)

1. Bend the hooks (A1) x 6 pcs., to remove the loading motor.

Figure 14-1

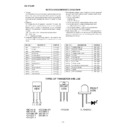

ADJUSTMENT

MECHANISM SECTION

•

Driving Force Check

Torque Meter

Specified Value

Play: TW-2111

Tape 1: Over 80 g

Tape 2: Over 80 g

Tape 2: Over 80 g

•

Torque Check

Torque Meter

Tape 2

Play: TW-2111

30 to 80 g.cm

30 to 80 g.cm

Fast forward: TW-2231

—

70 to 180 g.cm

Rewind: TW-2231

—

70 to 180 g.cm

Specified Value

Tape 1

Specified

Value

Adjusting

Point

Instrument

Connection

Test Tape

Normal

MTT-111

Variable

3,000

±

30 Hz

Speaker

speed

Resistor in

Terminal

motor.

(Load

resistance:

6 ohms)

resistance:

6 ohms)

•

Tape Speed

Figure 14-3

(B3) x 2

ø2.6 x 6mm

ø2.6 x 6mm

Shaft

(B4) x 1

(B4) x 1

Stop Washer

(B1) x 1

(B1) x 1

Gear

(B2) x 1

(B2) x 1

CD Mechanism

Pickup

TAPE MECHANISM

Tape

Motor

Motor

Variable Resistor in motor

(A1) x 6

Loading

Motor PWB

Motor PWB

Loading

Motor

Motor

Loading

Tray

Tray

– 15 –

CD-XP300H

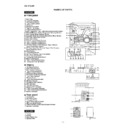

Figure 15-2

CD ERROR CODE DESCRIPTION

Error

Explanation

01

When Pickup set inner position, inner switch

cannot detect 'ON' level for 10 secs.

cannot detect 'ON' level for 10 secs.

When tray moves to Open/Close, Open/Close switch

10*

cannot detect 'ON' level for 7 secs.

When disc table rotate to target position.

Clamp switch cannot detect 'ON' level for 7 secs.

When disc table rotate to target position.

Clamp switch cannot detect 'ON' level for 7 secs.

When disc table set to Disc1 position for 1 st time,

11*

"CLAMP SW", "DISC NO SW" and "OPEN/CLOSE"

cannot detect 'ON' level for 14 secs.

cannot detect 'ON' level for 14 secs.

31

When it changes to CD function, DSP cannot read

initial data.

initial data.

T

T

EFBL

FDO

TE

Stopped

CH1=500 mV

DC 10:1

CH2=200 mV

DC 10:1

CH3=1 V

DC 10:1

500 ms/div

(500 ms/div)

NORM:20 kS/s

1

2

3

=Record Length=

Smoothing : ON

CH1 : 0.000 V

CH2 : 0.000 V

CH2 : 0.000 V

Main : 100 K

Zoom : 2 k

Zoom : 2 k

Mode : SINGLE

Type : EDGE CH1

Delay : 0.0 ns

Hold off : 0.2

Type : EDGE CH1

Delay : 0.0 ns

Hold off : 0.2

µ

s

CH3 : 0.00 V

CH4 : 0.00 V

CH4 : 0.00 V

BW : FULL

=Trigger=

=Filter=

=Offset=

CH2

v/DIV

200 mV

v/DIV

200 mV

1999/04/05 20:26:47

Test Stage

Frequency

Frequency

Display

Setting/

Adjusting

Parts

Instrument

Connection

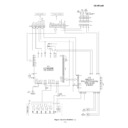

CD SECTION

•

AM IF/RF

Signal generator: 400 Hz, 30%, AM modulated

*1. Input: Antenna

Output: TP302

*2. Input: Antenna

Output: TP301

TUNER SECTION

fL: Low-range frequency

fH: High-range frequency

fH: High-range frequency

AM IF

450 kHz

1,620 kHz

T351

*1

AM Band

—

522 kHz

(fL): T306

*2

Coverage

1.1

±

0.1 V

AM Tracking 990 kHz

990 kHz

(fL): T303

*1

Figure 15-1 ADJUSTMENT POINTS

Items adjusted automatically

(1) Offset adjustment (The offset voltage between the head

amplifier output and the VREF reference voltage is

compensated inside the IC.)

compensated inside the IC.)

* Focus offset adjustment

* Tracking offset adjustment

* Tracking offset adjustment

(2) Tracking balance adjustment (waveform drawing

Fig.15-2 EFBL)

(3) Gain adjustment (The gain is compensated inside the IC

so that the loop gain at the gain crossover frequency will

be 0 dB.)

be 0 dB.)

* Focus gain adjustment

* Tracking gain adjustment

* Tracking gain adjustment

• Adjustment

AM IF

TP301

TP302

R381

R357

T303

T306

L354

T351

CNP301

AM LOOP

ANTENNA

AM LOOP

ANTENNA

AM BAND

COVERAGE fL

COVERAGE fL

AM TRACKING

fL

fL

MAIN PWB

FE301

SO301

FM ANTENNA

TERMINAL

FM ANTENNA

TERMINAL

* 'CHECKING'

If Error is detected, 'CHECKING' will be display instead of 'ER-

CD**' display. 'ER-CD**' display will only be display when

error had been detected for the 5 th times.

If Error is detected, 'CHECKING' will be display instead of 'ER-

CD**' display. 'ER-CD**' display will only be display when

error had been detected for the 5 th times.

• FM IF

Notes:

1: Description of the "FM IF Adjustment" is not carried on this

Notes:

1: Description of the "FM IF Adjustment" is not carried on this

Manual. It is because the IF coil in the FM front end section

has been best adjusted in the factory so that its further

adjustment is not needed at the field. When replacing the

FM front end assembly, no adjustment is needed either.

has been best adjusted in the factory so that its further

adjustment is not needed at the field. When replacing the

FM front end assembly, no adjustment is needed either.

2: The parts in the FM front end section are prepared in a

complete unit, so you can't obtain each part individually.

Display