Read Sharp PZ-50HV2E (serv.man4) Service Manual online

5

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

PZ-50HV2U

SAFETY INFORMATION

This service manual is intended for qualified service technicians ; it is not meant for the casual do-it-

yourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

yourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to cause

cancer, birth defects or other reproductive harm.

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to cause

cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PWB indicate that replacement parts must

be of identical designation.

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PWB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

SAFETY PRECAUTIONS

NOTICE :Comply with all cautions and safety related notes

located on or inside the cabinet and on the chassis.

The following precautions should be observed :

1. When service is required, even though the PDP UNIT an

1. When service is required, even though the PDP UNIT an

isolation transformer should be inserted between the power

line and the set in safety before any service is performed.

line and the set in safety before any service is performed.

2. When replacing a chassis in the set, all the protective

devices must be put back in place, such as barriers,

nonmetallic knobs, adjustment and compartment

covershields, isolation resistor-capacitor, etc.

nonmetallic knobs, adjustment and compartment

covershields, isolation resistor-capacitor, etc.

3. When service is required, observe the original lead dress.

Extra precaution should be taken to assure correct lead

dress in the high voltage circuitry area.

dress in the high voltage circuitry area.

4. Always use the manufacture's replacement components.

Especially critical components as indicated on the circuit

diagram should not be replaced by other manufacture's.

Furthermore where a short circuit has occurred, replace

those components that indicate evidence of overheating.

diagram should not be replaced by other manufacture's.

Furthermore where a short circuit has occurred, replace

those components that indicate evidence of overheating.

5. Before returning a serviced set to the customer, the service

technician must thoroughly test the unit to be certain that it

is completely safe to operate without danger of electrical

shock, and be sure that no protective device built into the

set by the manufacture has become defective, or

inadvertently defeated during servicing. Therefore, the

following checks should be performed for the continued

protection of the customer and service technician.

is completely safe to operate without danger of electrical

shock, and be sure that no protective device built into the

set by the manufacture has become defective, or

inadvertently defeated during servicing. Therefore, the

following checks should be performed for the continued

protection of the customer and service technician.

6. Perform the following precautions against unwanted

radiation and rise in internal temperature.

• Always return the internal wiring to the original styling.

• Attach parts (Gascket, Ferrite Core, Ground, Rear Cover,

• Always return the internal wiring to the original styling.

• Attach parts (Gascket, Ferrite Core, Ground, Rear Cover,

Shield Case etc.) surely after disassembly.

7. Perform the following precautions for the PDP panel.

• When the front case is removed, make sure nothing hits

the panel face, panel corner, and panel edge (so that the

glass does not break).

glass does not break).

• Make sure that the panel vent does not break. (Check

that the cover is attached.)

• Handle the FPC connected to the panel carefully.

Twisting or pulling the FPC when connecting it to the

connector will cause it to peel off from the panel.

connector will cause it to peel off from the panel.

8. Pay attention to the following.

• Be sure to wire the fan. If the fan does not work, the

temperature will rise and cause the protection circuit to

operate.

operate.

• When the front case is removed, infrared ray is radiated

and may disturb reception of the remote control unit.

• Pay extreme caution when the front case and rear panel

are removed because this may cause a high risk of

disturbance to TVs and radios in the surrounding.

disturbance to TVs and radios in the surrounding.

6

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

PZ-50HV2U

Leakage Current Cold Check

With the AC plug removed from an AC power source, place

a jumper across the two plug prongs. Turn the AC power

switch on. Using an insulation tester (DC 500V), connect one

lead to the jumpered AC plug and touch the other lead to each

exposed metal part (input/output terminals, screwheads,

metal overlays, control shafts, etc.), particularly any exposed

metal part having a return path to the chassis. Exposed metal

parts having a return path to the chassis should have a

minimum resistor reading of 0.3M

a jumper across the two plug prongs. Turn the AC power

switch on. Using an insulation tester (DC 500V), connect one

lead to the jumpered AC plug and touch the other lead to each

exposed metal part (input/output terminals, screwheads,

metal overlays, control shafts, etc.), particularly any exposed

metal part having a return path to the chassis. Exposed metal

parts having a return path to the chassis should have a

minimum resistor reading of 0.3M

Ω

and a maximum resistor

reading of 5M

Ω

. Any resistor value below or above this range

indicates an abnormality which requires corrective action.

Exposed metal parts not having a return path to the chassis

Exposed metal parts not having a return path to the chassis

will indicate an open circuit.

Leakage Current Hot Check

Plug the AC line cord directly into an AC power source (do not

use an isolation transformer for this check).

Turn the AC power switch on.

Using a "Leakage Current Tester (Simpson Model 229

equivalent)", measure for current from all exposed metal

parts of the cabinet (input/output terminals, screwheads,

metal overlays, control shaft, etc.), particularly any exposed

metal part having a return path to the chassis, to a known

earth ground (water pipe, conduit, etc.). Any current measured

must not exceed 0.5mA.

use an isolation transformer for this check).

Turn the AC power switch on.

Using a "Leakage Current Tester (Simpson Model 229

equivalent)", measure for current from all exposed metal

parts of the cabinet (input/output terminals, screwheads,

metal overlays, control shaft, etc.), particularly any exposed

metal part having a return path to the chassis, to a known

earth ground (water pipe, conduit, etc.). Any current measured

must not exceed 0.5mA.

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE SET TO THE CUSTOMER.

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE SET TO THE CUSTOMER.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in SHARP set have

special safety related characteristics. These are often not

evident from visual inspection nor the protection afforded by

them necessarily can be obtained by using replacement

components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are identified by

marking with a

special safety related characteristics. These are often not

evident from visual inspection nor the protection afforded by

them necessarily can be obtained by using replacement

components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are identified by

marking with a

å

on the schematics and on the parts list in

this Service Manual.

The use of a substitute replacement component which dose

not have the same safety characteristics as the SHARP

recommended replacement one, shown in the parts list in this

Service Manual, may create shock, fire or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current SHARP Service

Manual. A subscription to, or additional copies of, SHARP

Service Manual may be obtained at a nominal charge from

SHARP.

The use of a substitute replacement component which dose

not have the same safety characteristics as the SHARP

recommended replacement one, shown in the parts list in this

Service Manual, may create shock, fire or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current SHARP Service

Manual. A subscription to, or additional copies of, SHARP

Service Manual may be obtained at a nominal charge from

SHARP.

Device

under

test

under

test

Leakage

current

tester

current

tester

Reading should

not be above

0.5 mA

not be above

0.5 mA

Also test with

plug reversed

(Using AC adapter

plug as required)

plug reversed

(Using AC adapter

plug as required)

Test all

exposed metal

surfaces

exposed metal

surfaces

Earth ground

7

PZ-50HV2, PZ-50HV2E

PZ-50HV2U

PZ-50HV2U

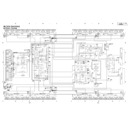

CHARGED SECTION AND HIGH VOLTAGE GENERATING POINT

Ë

Charged Section

1. AC Power Cord

2. AC Inlet with Filter

3. Power Switch (S1)

4. Fuse (In the SW POWER SUPPLY Module)

5. STB Transformer and Converter Transformer

(In the SW POWER SUPPLY Module)

6. Other primary side of the SW POWER SUPPLY Module

2. AC Inlet with Filter

3. Power Switch (S1)

4. Fuse (In the SW POWER SUPPLY Module)

5. STB Transformer and Converter Transformer

(In the SW POWER SUPPLY Module)

6. Other primary side of the SW POWER SUPPLY Module

Ë

High Voltage Generating Point

The places where voltage is 100V or more except for the

charged places described above. If the places are touched,

there is a risk of electric shock.

charged places described above. If the places are touched,

there is a risk of electric shock.

1. SW POWER SUPPLY Module .............................. (225V)

2. X DRIVE Assy ....................................... (–300V to 225V)

3. Y DRIVE Assy ....................................................... (355V)

4. SCAN (A) Assy ...................................................... (355V)

5. SCAN (B) Assy ...................................................... (355V)

6. X CONNECTOR (A) Assy ..................... (–300V to 225V)

7. X CONNECTOR (B) Assy ..................... (–300V to 225V)

2. X DRIVE Assy ....................................... (–300V to 225V)

3. Y DRIVE Assy ....................................................... (355V)

4. SCAN (A) Assy ...................................................... (355V)

5. SCAN (B) Assy ...................................................... (355V)

6. X CONNECTOR (A) Assy ..................... (–300V to 225V)

7. X CONNECTOR (B) Assy ..................... (–300V to 225V)

AC Inlet with Filter

Power Cord

Power Switch

(S1)

(S1)

Fig.1 Charged Section and High Voltage Generating Point (Rear View)

: Part is the High Voltage Generating Points

other than the Charged Section.

other than the Charged Section.

: Part is Charged Section.

X DRIVE

Assy

Assy

X CONNECTOR (B)

Assy

Assy

Y DRIVE

Assy

Assy

SCAN (A)

Assy

Assy

SCAN (B)

Assy

Assy

∗

Remove the IF Earth Metal beforehand when inclines

the power supply unit as the right figure.

the power supply unit as the right figure.

X CONNECTOR (A)

Assy

Assy

SW POWER SUPPLY

Module

Module

Top

Front