Read Sharp XV-Z21000 (serv.man4) Service Manual online

XV-Z20000/XV-Z21000/DT-5000

4 – 1

XV-Z20000

Service Manual

CHAPTER 4.

ELECTRICAL ADJUSTMENT

[1] ELECTRICAL ADJUSTMENT

The unit has been adjusted optimally at the time of factory shipment. However, if the screen position is deviated or when exchanging parts, make an

adjustment as shown below.

adjustment as shown below.

• Turn on the power (lamp on state) and wait for 15 minutes for aging.

• Enter the adjustment process mode with SW2002 (tact switch) on the main unit.

• Select the group to adjust with the DOWN (

) key or the UP (

) key on the remote control, and enter the adjustment item with the ENTER

(

) key on the remote control.

• Select the adjustment item with the DOWN (

) key or the UP (

) key on the remote control.

• Use the LEFT (

) key or the RIGHT (

) key for adjustment.

• To return from the adjustment item to the adjustment group, use the UNDO (

) key.

• To exit the adjustment process mode, execute the factory setting at the end of the adjustment.

<Cautions for adjustment>

1. Initialization and factory setting

If the initialization S1 or the factory setting S5 of EEPROM is carried out, time for writing the data is necessary.

When executing EEPROM initialization S1 or S5, the OSD of adjustment process mode disappears, and the OSD of SET1 or SET5 appears. After

completing setting, the input is switched automatically (SET1: DVI A-RGB input, SET5: C1). Never turn off the power until the input is switched (a

little less than 1 minute).

completing setting, the input is switched automatically (SET1: DVI A-RGB input, SET5: C1). Never turn off the power until the input is switched (a

little less than 1 minute).

No.

Adjusting point

Adjusting conditions

Adjusting procedure

1

EEPROM initialization

1. Turn on the power (with the lamp on) and

warm up the set for 15 minutes.

warm up the set for 15 minutes.

1. Make the following settings.

Press SW2002 to enter the process mode, and exe-

cute S1 to initialize EEPROM.

After executing S1, the input switches to DVI-

AnalogRGB.

S1: Main and Sub EEPROM initialization

S2: Sub EEPROM initialization

Press SW2002 to enter the process mode, and exe-

cute S1 to initialize EEPROM.

After executing S1, the input switches to DVI-

AnalogRGB.

S1: Main and Sub EEPROM initialization

S2: Sub EEPROM initialization

2

MODEL setting and model name

check

check

Process menu: LINE

Select MODEL.

Select MODEL.

MODEL 0 DT5000

1 XVZ20000

2 XVZ21000

After setting, check that the model name displayed in

the first line of process menu is the same as the set-

ting.

1 XVZ20000

2 XVZ21000

After setting, check that the model name displayed in

the first line of process menu is the same as the set-

ting.

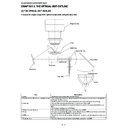

3

Color wheel sequence setting

Check the number marked at CW.

Adjustment group: DLP

Adjustment item: SEQUENCE

Initial value: 2

Adjustment group: DLP

Adjustment item: SEQUENCE

Initial value: 2

Color wheel number: SEQUENCE number

1

2

3

4

Color wheel index adjustment

1. Adjustment device: DDP3021

2. Adjustment group: DLP

3. Adjustment item: CW-INDEX

Initial value: 40

The built-in pattern for INDEX adjustment is

displayed.

2. Adjustment group: DLP

3. Adjustment item: CW-INDEX

Initial value: 40

The built-in pattern for INDEX adjustment is

displayed.

1. Adjust the setting so that the R, G and B Ramp tone

pattern should be smooth without noises.

pattern should be smooth without noises.

1

2

3

R

W

G

B

XV-Z20000/XV-Z21000/DT-5000

4 – 2

5-1

R-bright/contrast adjustment

1. Device: AD998417

2. Adjustment group: AD (RGB)

(Process gamma linkage)

3. Adjustment item: R-BRIGHT

Initial value: 40

Adjustment item: R-D

Initial value: 60

4. Input terminal: DVI A-RGB (Input switch-

ing linkage)

5. Input signal: XGA

Wind pattern having 100% (0.7 Vpp) R sig-

nal and 0%

2. Adjustment group: AD (RGB)

(Process gamma linkage)

3. Adjustment item: R-BRIGHT

Initial value: 40

Adjustment item: R-D

Initial value: 60

4. Input terminal: DVI A-RGB (Input switch-

ing linkage)

5. Input signal: XGA

Wind pattern having 100% (0.7 Vpp) R sig-

nal and 0%

1. Observe the 0% portion.

2. Vary R-Bright (increment direction), and adjust to

the point reduced by 1 point from the point where

red bit dropout appears.

3. Observe the 100% portion.

4. Vary R-D (increment direction), and adjust to the

point raised by 2 points from the point where red bit

dropout appears.

2. Vary R-Bright (increment direction), and adjust to

the point reduced by 1 point from the point where

red bit dropout appears.

3. Observe the 100% portion.

4. Vary R-D (increment direction), and adjust to the

point raised by 2 points from the point where red bit

dropout appears.

5-2

G-bright/contrast adjustment

1. Device: AD998417

2. Adjustment group: AD (RGB)

(Process gamma linkage)

3. Adjustment item: G-BRIGHT

Initial value: 40

Adjustment item: G-D

Initial value: 60

4. Input terminal: DVI A-RGB (Input switch-

ing linkage)

5. Input signal: XGA

Wind pattern having 100% (0.7 Vpp) G

signal and 0%

2. Adjustment group: AD (RGB)

(Process gamma linkage)

3. Adjustment item: G-BRIGHT

Initial value: 40

Adjustment item: G-D

Initial value: 60

4. Input terminal: DVI A-RGB (Input switch-

ing linkage)

5. Input signal: XGA

Wind pattern having 100% (0.7 Vpp) G

signal and 0%

1. Observe the 0% portion.

2. Vary G-Bright (increment direction), and adjust to

the point reduced by 1 point from the point where

green bit dropout appears.

3. Observe the 100% portion.

4. Vary G-D (increment direction), and adjust to the

point raised by 2 points from the point where green

bit dropout appears.

2. Vary G-Bright (increment direction), and adjust to

the point reduced by 1 point from the point where

green bit dropout appears.

3. Observe the 100% portion.

4. Vary G-D (increment direction), and adjust to the

point raised by 2 points from the point where green

bit dropout appears.

5-3

B-bright/contrast adjustment

1. Device: AD998417

2. Adjustment group: AD (RGB)

(Process gamma linkage)

3. Adjustment item: B-BRIGHT

Initial value: 40

Adjustment item: B-D

Initial value: 60

4. Input terminal: DVI A-RGB (Input switch-

ing linkage)

5. Input signal: XGA

Wind pattern having 100% (0.7 Vpp) B sig-

nal and 0%

2. Adjustment group: AD (RGB)

(Process gamma linkage)

3. Adjustment item: B-BRIGHT

Initial value: 40

Adjustment item: B-D

Initial value: 60

4. Input terminal: DVI A-RGB (Input switch-

ing linkage)

5. Input signal: XGA

Wind pattern having 100% (0.7 Vpp) B sig-

nal and 0%

1. Observe the 0% portion.

2. Vary B-Bright (increment direction), and adjust to

the point reduced by 1 point from the point where

blue bit dropout appears.

3. Observe the 100% portion.

4. Vary B-D (increment direction), and adjust to the

point raised by 2 points from the point where blue

bit dropout appears.

2. Vary B-Bright (increment direction), and adjust to

the point reduced by 1 point from the point where

blue bit dropout appears.

3. Observe the 100% portion.

4. Vary B-D (increment direction), and adjust to the

point raised by 2 points from the point where blue

bit dropout appears.

6-1

Component R-offset

1. Adjustment device: AD998417

2. Adjustment group: AD (COMP)

(Process gamma linkage)

3. Adjustment item: CR-OFFSET

Initial value: 50

4. Input terminal: DVI A-Component

(Input switching linkage)

5. Input signal: Component 100% Ramp sig-

nal

2. Adjustment group: AD (COMP)

(Process gamma linkage)

3. Adjustment item: CR-OFFSET

Initial value: 50

4. Input terminal: DVI A-Component

(Input switching linkage)

5. Input signal: Component 100% Ramp sig-

nal

1. Vary CR-OFFSET, and place the red line appearing

near the center over the green line.

2. The line color turns yellow.

near the center over the green line.

2. The line color turns yellow.

6-2

Component B-offset

(Auto adjustment)

(Auto adjustment)

1. Adjustment device: AD998417

2. Adjustment group: AD (COMP)

(Process gamma linkage)

3. Adjustment item: CB-OFFSET

Initial value: 50

4. Input terminal: DVI A-Component

(Input switching linkage)

5. Input signal: Component 100% Ramp sig-

nal

2. Adjustment group: AD (COMP)

(Process gamma linkage)

3. Adjustment item: CB-OFFSET

Initial value: 50

4. Input terminal: DVI A-Component

(Input switching linkage)

5. Input signal: Component 100% Ramp sig-

nal

1. Vary CB-OFFSET, and place the blue line over the

line turning yellow by CR-OFFSET adjustment.

2. The line color turns white.

line turning yellow by CR-OFFSET adjustment.

2. The line color turns white.

6-3

Component G-bright

1. Adjustment device: AD998417

2. Adjustment group: AD (COMP)

(Process gamma linkage)

3. Adjustment item: G-BRIGHT

Initial value: 70

4. Input terminal: DVI A-Component

(Input switching linkage)

5. Component wind pattern having 100%

(0.7 Vpp) G signal and 0%

6. Perform adjustment after adjusting CR-

OFFSET and CB-OFFSET.

2. Adjustment group: AD (COMP)

(Process gamma linkage)

3. Adjustment item: G-BRIGHT

Initial value: 70

4. Input terminal: DVI A-Component

(Input switching linkage)

5. Component wind pattern having 100%

(0.7 Vpp) G signal and 0%

6. Perform adjustment after adjusting CR-

OFFSET and CB-OFFSET.

1. Observe the 0% portion.

2. Vary G-BRIGHT (decrement direction), and the

screen starts to whiten.

3. Adjust to the point where no bit dropout is found

and the screen becomes completely white.

2. Vary G-BRIGHT (decrement direction), and the

screen starts to whiten.

3. Adjust to the point where no bit dropout is found

and the screen becomes completely white.

No.

Adjusting point

Adjusting conditions

Adjusting procedure

XV-Z20000/XV-Z21000/DT-5000

4 – 3

Do not change the process adjustment values other than the above since they are set so that optimal images are obtained.

6-4

Component RGB-gain adjust-

ment

(Auto adjustment)

ment

(Auto adjustment)

1. Adjustment device: AD998417

2. Adjustment group: AD (COMP) (Process

gamma linkage)

3. Adjustment item: G-D

Initial value: 70

4. Input terminal: DVI A-Component

(Input switching linkage)

5. Component wind pattern having 100%

(0.7 Vpp) G signal and 0%

6. Perform adjustment after adjusting CR-

OFFSET, CB-OFFSET and G-BRIGHT.

2. Adjustment group: AD (COMP) (Process

gamma linkage)

3. Adjustment item: G-D

Initial value: 70

4. Input terminal: DVI A-Component

(Input switching linkage)

5. Component wind pattern having 100%

(0.7 Vpp) G signal and 0%

6. Perform adjustment after adjusting CR-

OFFSET, CB-OFFSET and G-BRIGHT.

1. Observe the 100% portion.

2. Vary G-GAIN (decrement direction), and the illumi-

nance and chromaticity start to change.

3. Adjust to the point raised by 2 points from the point

where bit dropout appears on the screen.

2. Vary G-GAIN (decrement direction), and the illumi-

nance and chromaticity start to change.

3. Adjust to the point raised by 2 points from the point

where bit dropout appears on the screen.

7

White balance adjustment

1. Adjustment device: DDP3021

2. Adjustment group: DLP

3. Adjustment item: R-GAIN

Initial value: 95

B-GAIN

Initial value: 95

4. Input terminal: DVI A-Component

(Input switching linkage)

5. Input signal: Component 75% gray signal

2. Adjustment group: DLP

3. Adjustment item: R-GAIN

Initial value: 95

B-GAIN

Initial value: 95

4. Input terminal: DVI A-Component

(Input switching linkage)

5. Input signal: Component 75% gray signal

1. Observe the chromaticity of 75% portion using

CL200.

2. Adjust the y value to adjustment chromaticity

CL200.

2. Adjust the y value to adjustment chromaticity

±

0.005 with B-GAIN.

3. Adjust the x value to adjustment chromaticity

3. Adjust the x value to adjustment chromaticity

±

0.005 with R-GAIN.

Adjustment chromaticity

x = 0.299

Adjustment chromaticity

x = 0.299

±0.005

y = 0.316

±0.005

8

Factory setting

1. Group: SSS

1. Perform the following settings.

Destination Process adjustment Remote control

setting

Europe: S3 Factory setting 3

North America: S4 Factory setting 4

Japan: S5 Factory setting 5

China: S6 Factory setting 6

South America: S7 Factory setting 7

Destination Process adjustment Remote control

setting

Europe: S3 Factory setting 3

North America: S4 Factory setting 4

Japan: S5 Factory setting 5

China: S6 Factory setting 6

South America: S7 Factory setting 7

No.

Adjusting point

Adjusting conditions

Adjusting procedure

XV-Z20000/XV-Z21000/DT-5000

4 – 4

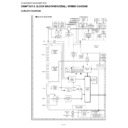

[2] Process menu

Group

Subject

AD (RGB)

R-BRIGHT

Adjustment Value

Subject

G-BRIGHT

Adjustment Value

Subject

B-BRIGHT

Adjustment Value

Subject

R-D

Adjustment Value

Subject

G-D

Adjustment Value

Subject

B-D

Adjustment Value

Subject

AD-AUTO

—

No Use

AD (COMP)

G-BRIGHT

Adjustment Value

Subject

CR-OFFSET

Adjustment Value

Subject

CB-OFFSET

Adjustment Value

Subject

G-D

Adjustment Value

Subject

COMP-AUTO

0

Fixed Value

DLP

CW-INDEX

Adjustment Value

Subject

DLP-GAMMA

1

Fixed Value

R-BRIGHT

100

Fixed Value

G-BRIGHT

100

Fixed Value

B-BRIGHT

100

Fixed Value

R-GAIN

Adjustment Value

Subject

G-GAIN

95

Fixed Value

B-GAIN

Adjustment Value

Subject

CCA

0

Fixed Value

SEQUENCE

Adjustment Value

Subject

VIDEO1

PICTURESUB

128

Fixed Value

PICTURE

136

Fixed Value

BRIGHT

128

Fixed Value

TINT

128

Fixed Value

N-COLOR

128

Fixed Value

P-COLOR

120

Fixed Value

SV-COLOF

5

Fixed Value

YGC-CNT

0

Fixed Value

SETUP

1

Fixed Value

CTI

7

Fixed Value

N358DLY

7

Fixed Value

PALDLY

7

Fixed Value

H-CENTER

128

Fixed Value

VIDEO-AUTO

0

Fixed Value

VIDEO2

YTRAP FILNP

0

Fixed Value

CTRAP FILNP

0

Fixed Value

YTRAP FILS

1

Fixed Value

CTRAP FILS

2

Fixed Value

YCTRAP FIL

1

Fixed Value

YCTRAP GAIN

0

Fixed Value

FCTRAP SYS

1

Fixed Value

PEAK GAIN

128

Fixed Value

PEAK FIL

2

Fixed Value

PEAK CORING

0

Fixed Value

CR LPF

1

Fixed Value

CB LPF

1

Fixed Value

OUTPUT

R1-GAIN

128

Fixed Value

G1-GAIN

128

Fixed Value

B1-GAIN

128

Fixed Value

V-R1-GAIN

128

Fixed Value

V-G1-GAIN

128

Fixed Value

V-B1-GAIN

128

Fixed Value

C-R1-GAIN

128

Fixed Value

C-G1-GAIN

128

Fixed Value

C-B1-GAIN

128

Fixed Value

LINE

MODEL

Setting Value

Setting Item

TIME

—

Fixed Value

LAMP

0

Fixed Value

OFF

0

Fixed Value

TEMP OFF

4

Fixed Value

SENSOR CHECK

—

Fixed Value