Read Sharp XV-C2E (serv.man3) Service Manual online

XV-C2E

15

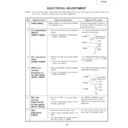

ELECTRICAL ADJUSTMENT

6

VCO

adjustment

(L4101)

adjustment

(L4101)

1. Keep the unit with no signal input.

2. Make connection between TP4101 and

GND.

3. Connect a frequency counter between

TP4102 and TP4101 (GND).

• Turn the core of L4101 to get the

frequency of 15.625±0.01 kHz.

5

PAL free-

running

frequency (2)

for high speed

(R4312, R4420)

running

frequency (2)

for high speed

(R4312, R4420)

1. Receive the PAL monoscope pattern

signal.

2. Connect the dual-beam oscilloscope to

TP4304 and TP4361.

• Turn R4312 and R4420 to obtain

the same waveform as for the

NTSC free-running frequency (2)

adjustment.

NTSC free-running frequency (2)

adjustment.

No.

Adjustment Item

Adjustment Conditions

Adjustment Procedure

1

Initial setting

Before starting the adjustments, initialize

the adjustment data.

the adjustment data.

Press the factory setting "2" button on

the process remote controller to reset

the adjustment data.

the process remote controller to reset

the adjustment data.

4

3

PLL adjustment

(PAL)

(R4339, R4340)

(PAL)

(R4339, R4340)

1. Receive the PAL monoscope pattern

signal.

2. Connect the dual-beam oscilloscope to

TP4305 and TP4306.

• Turn R4339 and R4340 to obtain the

same waveform as for the NTSC

PLL adjustment.

PLL adjustment.

PLL adjustment

(NTSC)

(R4347, R4349)

(NTSC)

(R4347, R4349)

2

1. Receive the NTSC monoscope pattern

signal.

2. Connect a dual-beam oscilloscope to

TP4305 and TP4306.

• Turn R4347 and R4349 to obtain the

waveform shown below.

NTSC free-

running

frequency (2)

for high speed

(R4341, R4343)

running

frequency (2)

for high speed

(R4341, R4343)

1. Receive the NTSC monoscope pattern

signal.

2. Connect the dual-beam oscilloscope to

TP4304 and TP4361.

• Turn R4341 and R4343 to obtain the

waveform shown below.

1

µ

s

GND

GND

2.5V

2.5V

H-SYNC

TP4305

TP4306

Pulse width to

be the same.

be the same.

1

µ

s

GND

GND

2.5V

2.5V

H-SYNC

TP4304

TP4361

Pulse width to

be the same.

be the same.

NOTE: The setting have been factory-adjusted to their best points. If any of them gets out of sprec or after any

relevant part has been replaced, make the related adjustment.

XV-C2E

16

No.

Adjustment Item

Adjustment Conditions

Adjustment Procedure

7

Horizontal

center

adjustment

(NTSC)(DAC)

center

adjustment

(NTSC)(DAC)

1. Receive the NTSC monoscope pattern

signal.

2. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group : VIDEO 1

Subject : H-CENT

• Using the

'

and

"

keys, make the

overscan just the same at right and

left.

left.

8

Horizontal

center

adjustment

(PAL)(DAC)

center

adjustment

(PAL)(DAC)

1. Receive the PAL monoscope pattern

signal.

2. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group :

VIDEO 1

Subject : PAL-H-CENT

• Using the

'

and

"

keys, make the

overscan just the same at right and

left.

left.

9

Contrast (DAC)

(gamma

correction off)

(gamma

correction off)

1. Receive the NTSC 10-step pattern

signal.

2. Connect the dual-beam oscilloscope

between pin (3) of P4201 and GND.

3. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group:

VIDEO 1

Subject: SUB-R, SUB-G, SUB-B

Make sure all these subjects have an

entry of 0 (zero).

entry of 0 (zero).

4. Adjust R861 to get the highest gain.

5. Finally select the following subject.

Group:

VIDEO 1

Subject: CONT

• Using the

'

and

"

keys, adjust the

difference between the 100% white

level and the pedestal level to

1.75±0.05 Vp-p.

level and the pedestal level to

1.75±0.05 Vp-p.

1. Receive the NTSC 10-step pattern

signal.

2. Connect the dual-beam oscilloscope

between pin (5) of P4201 and GND.

3. Put the video mode to the standard

setting.

10

Automatic gain

control (R861)

control (R861)

1. Receive the NTSC 10-step pattern

signal.

2. Connect the dual-beam oscilloscope

between pin (3) of P4201 and GND.

• Turn R861 so that the difference

between the 100% white level and the

pedestal level be 1.35±0.05 Vp-p.

pedestal level be 1.35±0.05 Vp-p.

11

D/A output level

adjustment

adjustment

• Turn R4270 so that the difference

between the 100% white level and the

pedestal level be 0.7±0.05 Vp-p.

pedestal level be 0.7±0.05 Vp-p.

XV-C2E

17

No.

Adjustment Item

Adjustment Conditions

Adjustment Procedure

12

D/A output level

adjustment

(PAL)(DAC)

adjustment

(PAL)(DAC)

1. Receive the PAL 10-step pattern signal.

2. Connect the dual-beam oscilloscope

between pin (5) of P4201 and GND.

3. Select the following subject.

Group : VIDEO 1

Subject : DAVREF

• Using the

'

and

"

keys, adjust the

difference between the 100% white

level and the pedestal level to

0.7±0.05 Vp-p.

level and the pedestal level to

0.7±0.05 Vp-p.

15

Gain

adjustment (1)

(DAC) (standard

video, gamma

correction off)

adjustment (1)

(DAC) (standard

video, gamma

correction off)

1. Receive the NTSC 10-step pattern

signal.

2. Connect the dual-beam oscilloscope

between pin (2) of P4303 and GND.

3. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group :

VIDEO 2

Subject : DRIVE 1

4. Connect the dual-beam oscilloscope

between pin (1) of P4303 and GND.

Subject: R-DRIVE

5. Next connect the dual-beam

oscilloscope between pin (3) of P4303

and GND.

and GND.

Subject: B-DRIVE

• Using the

'

and

"

keys, adjust the

difference between the 100% white

level and the pedestal level to

1.55±0.05 Vp-p.

level and the pedestal level to

1.55±0.05 Vp-p.

(DRIVE1, R-DRIVE, B-DRIVE)

13

Signal center

adjustment

(DAC) (gamma

correction off)

adjustment

(DAC) (gamma

correction off)

1. Receive the NTSC 10-step pattern

signal.

2. Connect the dual-beam oscilloscope

between pin (2) of P4303 and GND.

3. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group : VIDEO 2

Subject : SIG CTR

• Using the

'

and

"

keys, adjust the

center level of the waveform to DC

7.0±0.1 Vp-p.

7.0±0.1 Vp-p.

14

Reference level

adjustment

(DAC) (gamma

correction off)

adjustment

(DAC) (gamma

correction off)

1. Receive the NTSC 10-step pattern

signal.

2. Connect the dual-beam oscilloscope

between pin (2) of P4303 and GND.

3. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group :

VIDEO 2

Subject : SUB-BIAS

4. Connect the dual-beam oscilloscope

between pin (1) of P4303 and GND.

Subject : R-BIAS

5. Next connect the dual-beam

oscilloscope between pin (3) of P4303

and GND.

and GND.

Subject : B-BIAS

• Using the

'

and

"

keys, adjust the

difference between the waveform’s

reference level and the signal center

level to DC 2.0±0.1 Vp-p.

reference level and the signal center

level to DC 2.0±0.1 Vp-p.

(SUB-BIAS, R-BIAS, B-BIAS)

Waveform center level

GND

Waveform center level

XV-C2E

18

No.

Adjustment Item

Adjustment Conditions

Adjustment Procedure

16

Brightness

adjustment

(DAC) (gamma

correction off)

adjustment

(DAC) (gamma

correction off)

Note :

After this

adjustment, go

back to Item 15

"Gain adjustment".

Readjust the gain

level.

adjustment, go

back to Item 15

"Gain adjustment".

Readjust the gain

level.

1. Receive the 10-step pattern signal.

2. Connect the dual-beam oscilloscope

between pin (2) [pin (1) for red, pin (3)

for blue] of P4303 and GND.

for blue] of P4303 and GND.

3. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group : VIDEO 1

Subject : BRIGHT(G), R-BRT, B-BRT

• Using the

'

and

"

keys, adjust the

difference between the 100% white

level and the pedestal level to

5.9±0.1 Vp-p.

level and the pedestal level to

5.9±0.1 Vp-p.

17

Gamma

adjustment

(DAC) (gamma

correction off)

adjustment

(DAC) (gamma

correction off)

1. Receive the NTSC 10-step pattern

signal.

2. Connect the dual-beam oscilloscope

between pin (2) of P4303 and GND.

3. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group : VIDEO 4

Subject : RGB GAM1, RGB CTR1

4. Connect the dual-beam oscilloscope

between pin (1) of P4303 and GND.

5. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group : VIDEO 4

Subject : R GAM1, R CTR1

6. Connect the dual-beam oscilloscope

between pin (1) of P4303 and GND.

7. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group : VIDEO 4

Subject : B GAM1, B CTR1

• Using the

'

and

"

keys, adjust the

second-tone level to 4.2±0.1 Vp-p

and the black level to 3.0±0.1 Vp-p.

and the black level to 3.0±0.1 Vp-p.

18

SID signal level

adjustment

adjustment

1. Receive the NTSC 10-step pattern

signal.

2. Connect the dual-beam oscilloscope

between pin (6) of P4303 and GND.

3. Press S2001 to call up the ADJ IN

mode and select the following subject.

Group:

VIDEO 3

Subject: SID CTR

• Using the

'

and

"

keys, adjust the

waveform’s top and bottom levels

from its center level to 4.0±0.1 Vp-p.

from its center level to 4.0±0.1 Vp-p.

GND

GND

Black level

Second-tone level

4.0V

4.0V