Read Sharp PG-F150X (serv.man2) Service Manual online

PG-F150X

ii

PG-F150X

Service Manual

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY NOTES

IMPORTANT SERVICE SAFETY NOTES

Service work should be performed only by qualified service technicians who are

thoroughly familiar with all safety checks and servicing guidelines as follows:

thoroughly familiar with all safety checks and servicing guidelines as follows:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE PROJECTOR:

(Fire & Shock Hazard)

(Fire & Shock Hazard)

Before returning the projector to the user, perform

the following safety checks:

1. Inspect lead wires are not pinched between the chassis

the following safety checks:

1. Inspect lead wires are not pinched between the chassis

and other metal parts of the projector.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators, etc.

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators, etc.

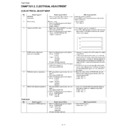

3. To be sure that no shock hazard exists, check for

current leakage in the following manner:

Plug the AC cord directly into a 120 - volt AC outlet,

(Do not use an isolation transformer for this test).

Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in parallel

between all exposed metal cabinet parts and earth

ground.

Plug the AC cord directly into a 120 - volt AC outlet,

(Do not use an isolation transformer for this test).

Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in parallel

between all exposed metal cabinet parts and earth

ground.

Use an AC voltmeter with sensitivity of 5000 ohm per

volt., or higher, sensitivity to measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC plug

connection reversed. (If necessary, a non-polarized

adapter plug must be used only for the purpose of

completing these checks.)

Any reading of 0.4 volts RMS (this corresponds to 0.27

milliamp. AC.) or more is excessive and indicates a

potential shock hazard which must be corrected before

returning the unit to the owner

volt., or higher, sensitivity to measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC plug

connection reversed. (If necessary, a non-polarized

adapter plug must be used only for the purpose of

completing these checks.)

Any reading of 0.4 volts RMS (this corresponds to 0.27

milliamp. AC.) or more is excessive and indicates a

potential shock hazard which must be corrected before

returning the unit to the owner

.

SAFETY NOTICE

Many electrical and mechanical parts in DLP

Projector have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by “

Projector have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by “

”

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams. For continued protection,

Schematic Diagrams. For continued protection,

replacement parts must be identical to those used in

the original circuit. The use of a substitute replacement

parts which do not have the same safety characteristics

as the factory recommended replacement parts shown

in this service manual, may create shock, fire or other

hazards.

the original circuit. The use of a substitute replacement

parts which do not have the same safety characteristics

as the factory recommended replacement parts shown

in this service manual, may create shock, fire or other

hazards.

WARNING: The bimetallic component has the primary

conductive side exposed. Be very careful in

handling this component when the power is on.

handling this component when the power is on.

DVM

AC SCALE

1.5k ohm

10W

TO EXPOSED

METAL PARTS

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

KNOWN EARTH

GROUND

0.15 µF

TEST PROBE

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

R

PG-F150X

iii

NOTE TO SERVICE

PERSONNEL

PERSONNEL

UV-RADIATION PRECAUTION

The light source, lamp, in the projector emits small

amounts of UV-Radiation.

AVOID DIRECT EYE AND SKIN EXPOSURE.

To ensure safety please adhere to the following:

1. Be sure to wear sun-glasses when servicing the

projector with the lamp

turned “on” and the top

enclosure removed.

turned “on” and the top

enclosure removed.

2. Do not operate the lamp outside of the lamp housing.

3. Do not operate for more than 2 hours with the enclosure

removed.

UV-Radiation and Medium Pressure

Lamp Precautions

Lamp Precautions

1. Be sure to disconnect the AC plug when replacing the

lamp.

2. Allow one hour for the unit to cool down before

servicing.

3. Replace only with same type lamp. Type AN-XR30LP

rated 200W DC.

4. The lamp emits small amounts of UV-Radiation, avoid

direct-eye contact.

5. The medium pressure lamp involves a risk of explosion.

Be sure to follow installation instructions described

below and handle the lamp with care.

below and handle the lamp with care.

//////////////////////////////////////////////////////////////

//////////////////////////////////////////////////////////////

1

2

2

Lamp

Reflector

Since small amounts of UV-radiation are emitted

from an opening between the exhaust fans, it is rec-

ommended to place the cap of the optional lens on

the opening during servicing to avoid eye and skin

exposure.

from an opening between the exhaust fans, it is rec-

ommended to place the cap of the optional lens on

the opening during servicing to avoid eye and skin

exposure.

DANGER ! –– Never turn the power on without the

lamp to avoid electric-shock or damage of the devices

since the stabilizer generates high voltages at its start.

lamp to avoid electric-shock or damage of the devices

since the stabilizer generates high voltages at its start.

UV-RADIATION PRECAUTION (Continued)

Lamp Replacement

Note:

Since the lamp reaches a very high temperature during

units operation replacement of the lamp should be

done at least one hour after the power has been turned

off. (to allow the lamp to cool off.)

Installing the new lamp, make sure not to touch the

lamp (bulb) replace the lamp by holding its reflector

units operation replacement of the lamp should be

done at least one hour after the power has been turned

off. (to allow the lamp to cool off.)

Installing the new lamp, make sure not to touch the

lamp (bulb) replace the lamp by holding its reflector

.

[Use original replacement only.]

////////////////////////////////////////////////////////////////

////////////////////////////////////////////////////////////////

PG-F150X

iv

WARNING:

High brightness light source, do not stare into the beam of light, or view directly. Be especially

careful that children do not stare directly into the beam of light.

careful that children do not stare directly into the beam of light.

WARNING:

TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS UNIT TO

MOISTURE OR WET LOCATIONS.

MOISTURE OR WET LOCATIONS.

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE CABINET.

NO USER-SERVICEABLE PARTS EXCEPT LAMP UNIT.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

The lighting flash with arrowhead within a

triangle is intended to tell the user that

parts inside the product are risk of electric

shock to persons.

triangle is intended to tell the user that

parts inside the product are risk of electric

shock to persons.

The exclamation point within a triangle is

intended to tell the user that important

operating and servicing instructions are in

the manual with the projector.

intended to tell the user that important

operating and servicing instructions are in

the manual with the projector.

CAUTION

RISK OF ELECTRIC SHOCK.

DO NOT REMOVE SCREWS

DO NOT REMOVE SCREWS

EXCEPT SPECIFIED USER

SERVICE SCREW.

CAUTION

(POWER Unit)

For continued

protection against a

risk of fire, replace

only with same type

6.3A, AC250V fuse.

(F701)

protection against a

risk of fire, replace

only with same type

6.3A, AC250V fuse.

(F701)

6.3A 250V

PG-F150X

v

Precautions for using lead-free solder

Employing lead-free solder

• "PWBs" of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals. The

alphabetical character following LF shows the type of lead-free solder.

Example:

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause dam-

age or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40

°C, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220

°C which is higher than the conventional lead solder by 40 °C, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

L

F a

Indicates lead-free solder of tin, silver and copper.

Part No.

Description

Code

ZHNDAi123250E

J

φ0.3mm 250g(1roll)

BL

ZHNDAi126500E

J

φ0.6mm 500g(1roll)

BK

ZHNDAi12801KE

J

φ1.0mm 1kg(1roll)

BM