Read Sharp MX-PNX1C (serv.man17) Technical Bulletin online

Date:

26

th

January 2009

Model:

MX-PNX1

Ref.:

001

Colour:

White

Page:

1 of 2

TECHNICAL BULLETIN

INCORRECT DETECTION OF "PUNCH DEBRIS

FULL" IN DUST BOX.

Sharp Electronics (UK) Ltd., Technical Services Group

CCE-623

1. Model Name: MX-PNX1A/B/C/D

(Options for MX-1800 Series/2000 Series/3000 Series/4000 Series/500* Series)

2. Symptom:

The punch unit (MX-PNX1A) for the inner finisher may display the message "Check the punch

debris unit" because it detected "punch debris full" although the dust box is not filled with

punch debris. If this message is displayed, the punch function may be disabled.

The punch unit for the inner finisher incorrectly detects that the dust box is filled with punch

debris if the movement of the punch debris diffusion plate slows down. The movement of the

punch diffusion plate slows down because the spacing between the punch debris diffusion

plate and connection gear becomes too narrow if the dust box moves to the right when

mounted.

If the dust box moves to the left, however, the punch unit does not incorrectly detect "punch

debris full" because a gap is secured between the punch debris diffusion plate and connection

gear and the movement of the punch diffusion plate becomes smooth.

debris unit" because it detected "punch debris full" although the dust box is not filled with

punch debris. If this message is displayed, the punch function may be disabled.

The punch unit for the inner finisher incorrectly detects that the dust box is filled with punch

debris if the movement of the punch debris diffusion plate slows down. The movement of the

punch diffusion plate slows down because the spacing between the punch debris diffusion

plate and connection gear becomes too narrow if the dust box moves to the right when

mounted.

If the dust box moves to the left, however, the punch unit does not incorrectly detect "punch

debris full" because a gap is secured between the punch debris diffusion plate and connection

gear and the movement of the punch diffusion plate becomes smooth.

3. Description:

To prevent the dust box from moving to the right when mounted, we pasted a sheet to the right

side of the dust box, moved the dust box to the left, and secured a gap between the punch

debris diffusion plate and connection gear to smoothen the movement of the punch debris

diffusion plate.

We also found that if there is a sheet in a position where the punch debris diffusion plate

contacts and the punch debris diffusion plate is caught in the sheet, the movement of the

punch debris diffusion plate slows down. For this reason, we have abolished the sheet.

side of the dust box, moved the dust box to the left, and secured a gap between the punch

debris diffusion plate and connection gear to smoothen the movement of the punch debris

diffusion plate.

We also found that if there is a sheet in a position where the punch debris diffusion plate

contacts and the punch debris diffusion plate is caught in the sheet, the movement of the

punch debris diffusion plate slows down. For this reason, we have abolished the sheet.

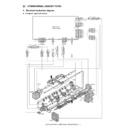

Additional sheet (thickness: 0.5 mm)

Sharp Electronics (UK) Ltd., Technical Services Group

CCE-623

Additional sheet pasting location and abolished sheet location

4. Action:

From mid-November 2008 production

5.Parts Action:

Ref.

No.

Model

name

Version P/G No.

Current parts

New parts

Price

rank

Q'ty Parts

name

Effective

time

Inter-

change-

ability

Parts code

Parts code

1

MX-PNX1A

MX-PNX1B

MX-PNX1C

MX-PNX1D

MX-PNX1B

MX-PNX1C

MX-PNX1D

ALL

14-

--- 0CW1035P363//

AK

1

Sheet

2008/11

Mid

---

14-55

0CW1035P345// --- ---

---

<Interchange>

1. Interchangeable.

4. Not interchangeable.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

5. Interchangeable if replaced with same types of

related parts in use.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

6. Others.

Parts marked with "

" is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

Display