Read Sharp MX-GB50A (serv.man6) Brochure online

- 1 -

Sales Guide

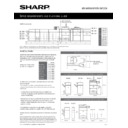

SmartPunch Pro

MX-GB50FK

MX-GB50FK

- 2 -

- 3 -

Introduction

Overview

The new GBC SmartPunch Pro is an optional hole punch unit available

for production configurations of the MX-M904/1054/1204 range.

The unit is designed and manufactured by GBC, an American

company who specialise in binding and lamination products. GBC has

company who specialise in binding and lamination products. GBC has

been manufacturing and supplying in-line punch units for light

production printers for 5 years. The GBC punch unit is also sold by

production printers for 5 years. The GBC punch unit is also sold by

Ricoh as the Ricoh Stream Punch, Canon as the Professional Punch A1,

Xerox as the Advanced Punch and Konica Minolta as the Multi

Xerox as the Advanced Punch and Konica Minolta as the Multi

Punching Unit.

Reasons for Launch

Essentially all in-line finishing options increase print volumes on the

machines to which they are attached. Whilst finishing options do

machines to which they are attached. Whilst finishing options do

increase average achieved revenue per sale, they are sales enablers.

Adding the GBC SmartPunch as a finishing option to Hercules further

strengthens Sharp Direct sales and Dealers opportunity to sell into

strengthens Sharp Direct sales and Dealers opportunity to sell into

larger printrooms and professional print establishments.

Comb

®

, Wire, Coil

®

, Velo

®

/Sure

®

remain the most economical binding

method found in the majority of centralised / managed or professional

print service environments. These binding methods can bind from 10

up to 500 pages and are suitable for short to medium life documents,

up to 500 pages and are suitable for short to medium life documents,

especially for internal use.

Product Overview

Improved Features

The new SmartPunch Pro has the same new appearance as the MX-

M904/M1054 and M1204. It also has the following improvements:

M904/M1054 and M1204. It also has the following improvements:

Chip Tray Sensing: Increases chip tray capacity so user does not

have to stop production as often to empty chips. Example for 4-

hole punch. Previous capacity was 3,500 sheets now 27,000

sheets

sheets

More robust parts for greater reliability – new stronger motors

and clutches

Life Rating improved from 24M in 5 years to 60M in 5 years

Duty Cycle improved from max. 300k to 500k sheets per month

Boot loader firmware: Technician can upload firmware via a

laptop and does not have to change microchip for new firmware

upgrade anymore

- 4 -

Installation

The new Smart Punch Pro must be installed with MXRB13

irrespective of whether the Multi-fold unit (MX-FD10) or Inserter (MX-

CF10) are part of the installation or not.

CF10) are part of the installation or not.

The unit can be fitted to existing MIF.

Diesets

The unit has customer inter-changeable punch diesets available for

punching holes in 11 different holes/patterns for the most popular

punching holes in 11 different holes/patterns for the most popular

mechanical binding systems available in the UK. There is space for

storage of 3 additional diesets in addition to the one loaded in the unit.

storage of 3 additional diesets in addition to the one loaded in the unit.

The unit punches individual sheets ‘on the fly’, at the rated speed of

the model to which it is attached, as they pass through the unit on the

way to the finisher output tray. Using the sort and offset features of

way to the finisher output tray. Using the sort and offset features of

the finisher (MX-FN21 or 22) the punched document sets are ready for

off-loading for the final step in the binding process.

off-loading for the final step in the binding process.

Monthly Volume Maximum

recommended

monthly

punches is 500k. As most

documents being bound are duplex, this represents 1000k pages.

Key Customer Benefit

The SmartPunch offers all print rooms or centralised managed print

environments, major time and labour saving benefits by drastically

cutting down on the time it takes to punch the holes using desktop

cutting down on the time it takes to punch the holes using desktop

mechanical binding devices.

Irrespective of type – electric or manual – or binding method (eg comb,

wire, Velo, coil), or cost, the maximum number of sheets that can be

punched at any one time is 35 (70 pages). The average is around 25.

This means that any document over 45 – 50 pages requires more than

This means that any document over 45 – 50 pages requires more than

one punch. The larger the document and quantity to be punched and

bound, the more time consuming and labour intensive the process.

bound, the more time consuming and labour intensive the process.

By punching the document on the fly during the print process, the

time consuming element of the process is eliminated, thereby reducing

the overall completion time.

the overall completion time.

Whilst the cost of an in-line punch unit is higher than the average

desktop binding device, if the time saved by eliminating the punching

part of the process is converted into labour cost saved, the

part of the process is converted into labour cost saved, the

SmartPunch pays for itself.