Read Sharp MX-FNX10 (serv.man38) Technical Bulletin online

Date:

2

nd

March 2009

Model:

MX-FN10

Ref.:

003

Colour:

Yellow

Page:

1 of 16

TECHNICAL BULLETIN

IMPROVEMENT OF SADDLE FINISHER

(MX-FN10).

Sharp Electronics (UK) Ltd., Technical Services Group

CCE-621

NOTE: IT IS ESSENTIAL THAT THE FIRMWARE BE UPGRADED TO VER 01b01.02 AT THE

EARLIEST OPORTUNITY, THIS IS AVAILABLE ON THE FN10 APRT OF THE

TECHNICAL WEBSITE

TECHNICAL WEBSITE

1. Model Name:

MX-FN10 (Option for MX-2600 Series/3100 Series/4100 Series/5000 Series)

2. Description:

1. In Technical Bulletin 001, we notified you of the countermeasure for the "F1-43 trouble"

resulting from the catch of an alignment plate. This time, we have changed the shape of the

alignment plate as the permanent countermeasure so that the alignment plate will not be

caught in the edge section of the plate guide.

alignment plate as the permanent countermeasure so that the alignment plate will not be

caught in the edge section of the plate guide.

2. Lateral motion of the saddle stapler may cause gear breakage, so we have changed the

POM gear to a metallic gear.

3.To increase the intensity of the stopper spring installation location of the tray base, we have

changed the shape of the tray base. Along with this change, we have also changed the

shape of the stopper spring.

shape of the stopper spring.

4. To prevent the front end of a paper sheet from rounding in the processor in punch mode or

to prevent the rear end of the paper sheet from being caught in switchback mode, we have

changed the shape of the weight to reduce the load to be applied to the paper sheet.

changed the shape of the weight to reduce the load to be applied to the paper sheet.

5. A corner of a paper sheet may be caught on the front side of the transport belt shaft section

to influence consistency. To prevent the corner of the paper sheet from being caught, we

have added a pulley and flange to the front side of the transport belt shaft section which the

corner of the paper sheet touches. Along with this addition, we have also changed the shaft

and clips.

have added a pulley and flange to the front side of the transport belt shaft section which the

corner of the paper sheet touches. Along with this addition, we have also changed the shaft

and clips.

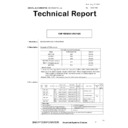

Status in which each part is mounted to the shaft

Sharp Electronics (UK) Ltd., Technical Services Group

CCE-621

Sharp Electronics (UK) Ltd., Technical Services Group

CCE-621

6. To cope with the "F1-08" trouble and saddle folding location correction, we have issued a

special ROM.

This special ROM is exclusively used for the field.

Version

01b01.02

Reason to change: In order to correct an error described below.

1. If the gripper opening is insufficient, the stapler may collide with the U-shaped plate in lateral

motion to cause the "F1-08" trouble. Insufficient gripper opening is caused when a mechanical

part rattles in the driving section.

part rattles in the driving section.

(This ROM is applicable to S/N 8L002667 and earlier but there is no problem if it is applied to

products after S/N 8L002667.)

Note) If a stapler phase deviation occurs in the "F1-08" trouble, check the gripper phase deviation

of the accompanying sheet and the Change Guidelines.

2. The folding location may shift, depending on the number of sheets to be bound.

3. Action:

1, 2: From middle of August 2008 production

3: From middle of September 2008 production

4,5: From middle of October 2008 production

4,5: From middle of October 2008 production

4. Parts Action:

Ref.

No.

Model

name

Version P/G

No.

Current parts

New parts

Price

rank

Q'ty Parts

name

Effective

time

Inter-

change-

ability

Parts code

Parts code

1

MX-FN10 ALL

19-30

0CW4158P564//

0CW4158P563//

AG

1

PLT-SD-SG-F

See

Action

3

0CW4158P564B/ PLT-SD-SG-R

2 21-62

0CW4158K142// 0CW4158K142B/ CW

SD-STAPLE-UNIT

3

22-32

0CW4158P550// 0CW4158P550G/ BF

TRAY-SD-BASE

5

SPRING-SD-

22-33

0CW4158P660// 0CW4158P660B/ AE

TRAY-STOP

4

8-5

0CW4143P042// 0CW4158P935// AF 2 WEIGHT-FE-PRO

3

5

7-1

0CW4158P268// 0CW4158P268E/ BB 1 SHAFT-FE-BELT

5

7-

0CWNSCLP00008

0CWCLP00005A/ AD 2 Clip

5

7-

--- 0CW4143P070//

AE

1

PLY-S2M-22L

7-

--- 0CW2147P032//

AC

FLNG-17-RK

<Interchange>

1. Interchangeable.

4. Not interchangeable.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

5. Interchangeable if replaced with same types of

related parts in use.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

6. Others.

Parts marked with "

" is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

Sharp Electronics (UK) Ltd., Technical Services Group

CCE-621