|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man6)

Service Manual (Revised May 2016).

Service Manual

|

127

|

29.56 MB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man7)

Installation Manual (Revised July 2014).

Service Manual

|

20

|

2.2 MB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man8)

Circuit Diagrams

Service Manual

|

99

|

3.58 MB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man9)

MX-CS11 Service Manual

Service Manual

|

13

|

1.5 MB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man12)

Start Guide

User Guide / Operation Manual

|

8

|

1.08 MB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man13)

Software Set-up Guide

User Guide / Operation Manual

|

44

|

1.71 MB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man14)

Operation Manual

User Guide / Operation Manual

|

127

|

24.5 MB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man15)

Revised Installation Manual

User Guide / Operation Manual

|

19

|

2.18 MB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man10)

Parts Guide (Revised June 2016).

Parts Guide

|

104

|

14.05 MB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man11)

PWB Parts Guide (Revised June 2014).

Parts Guide

|

40

|

587.89 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man4)

CCE829R5 PROCEDURES FOR USING SERVICE PERSONNEL-ORIENTED FUNCTIONS INSTALLED IN SHARP REMOTTE DEVICE MANAGER

Specification

|

18

|

2.11 MB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man5)

Specifications

Specification

|

8

|

814.15 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man53)

CCE1348 REMOVAL OF SHEETS ATTACHED TO 2ND TRANSFER UNIT

Technical Bulletin

|

2

|

121.12 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man59)

ROM UPGRADE ... (7).

Technical Bulletin

|

2

|

38.36 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man54)

CCE1349 REMOVAL OF THERMAL SHEET ON MFPC FIXING PLATE

Technical Bulletin

|

1

|

122.04 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man55)

CCE 1341 ROM UPGRADE 02.05.E1.00

Technical Bulletin

|

3

|

61.05 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man56)

CCE 1346 COUNTERMEASURE FOR NOISE FROM PAPER FEEDING ROLLER

Technical Bulletin

|

2

|

160.6 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man57)

CCE1338 CHANGE OF SERVICE PARTS CONFIGURATION-OPERATION PANEL UNIT SECTION

Technical Bulletin

|

3

|

235.88 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man58)

CCE1330 SET UP OF NEW SERVICE PARTS DELIVERY AUXILIARY GUIDE

Technical Bulletin

|

3

|

412.09 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man67)

CCE-1231 PRECAUTION FOR REMOVING OR REPLACING THE FFC

Technical Bulletin

|

4

|

1.11 MB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man52)

Countermeasures against contamination of paper surface.

Technical Bulletin

|

2

|

24.64 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man51)

CCE-1350 REMEDY FOR NOISE GENERATED WHILE FEEDING PAPER FROM MULTI MANUAL PAPER FEEDING UNIT

Technical Bulletin

|

2

|

86.34 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man50)

CCE-1366 REDUCTION OF A FERRITE CORE (BUNDLED WITH MAIN UNIT)

Technical Bulletin

|

1

|

90.85 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man49)

CCE-1363 IMPROVEMENT FOR H3 TROUBLE CODE ETC.

Technical Bulletin

|

3

|

364.77 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man48)

CCE-1391 MODIFICATION OF NOISE GENERATED WHILE FEEDING ORIGINAL

Technical Bulletin

|

3

|

225.39 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man47)

IMPORTANT Handling of EEPROM's.

Technical Bulletin

|

5

|

203.32 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man46)

CCE1440 ENHANCEMENT OF OPERABILITY IN OPENING CLOSING MULTI MANUAL PAPER FEEDING UNIT

Technical Bulletin

|

2

|

156.98 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man45)

CCE 1460 CHANGE IN COLOR OF BELT COUPLING JOINT

Technical Bulletin

|

2

|

169.78 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man60)

CCE-1317 OPEN SSL VULNERABILITY FIRMWARE RELEASE FOR FIELD SUPPORT VERSION

Technical Bulletin

|

4

|

242.22 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man62)

Procedure for using Service Personnel Oriented Functions in Sharp Remote Device Manager.

Technical Bulletin

|

18

|

2.11 MB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man63)

CCE-1281 SOLUTION FOR PAPER JAM (AT SPPD1_NR ETC.) DUE TO THE WARPING OF REVERSE SELF WEIGHT GATE

Technical Bulletin

|

2

|

134.34 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man64)

CCE-1260 COUNTERMEASURE FOR INCONSISTENCIES IN PITCH BY CHANGING TYPE OF GEAR OF MAIN DRIVE UNIT

Technical Bulletin

|

2

|

102.4 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man65)

CCE-1259 NOISE FROM MAIN DRIVE UNIT

Technical Bulletin

|

2

|

284.82 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man66)

CCE-1258 OPERATING SOUND OF FUSING COOLING FAN IN PRE-HEAT MODE

Technical Bulletin

|

1

|

14.55 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man38)

CCE1501 CHANGE IN FERRITE CORE FOR FAX LINE CABLE

Technical Bulletin

|

2

|

273.37 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man68)

CCE1252 OPERATING SOUND REDUCTION DURING MANUAL PAPER FEEDING

Technical Bulletin

|

2

|

115.78 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man69)

CCE1249 IMPROVED DENSITY UNEVENNESS BY ADDING SPF RSPF REAR MYLAR

Technical Bulletin

|

2

|

202.64 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man70)

CCE1248 SHAPE CHANGE OF INTERIOR EXHAUST INTAKE DUCT COVER FOR PRODUCTIVITY IMPROVEMENT

Technical Bulletin

|

2

|

99.06 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man71)

CCE1246 MODIFICATION OF NOISE WHILE REVERSE GATE IS MOVING

Technical Bulletin

|

2

|

77.92 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man72)

CCE1245 IMPROVEMENT FOR SILENCING OF RSPF MOTOR NOISE

Technical Bulletin

|

2

|

245.39 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man73)

IMPROVEMENT FOR NOISE FROM RSPF UNIT

Technical Bulletin

|

1

|

47.04 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man74)

Bulletin for ROM Update 01.10.E1.00

Technical Bulletin

|

4

|

49.03 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man75)

PREVENTION OF L4-06 ERROR DUE TO THE DAMAGE ON 1TUD HARNESS

Technical Bulletin

|

2

|

197.44 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man29)

CCE-1759R SERVICE PARTS SETUP OF FUSING SECTION

Technical Bulletin

|

3

|

554.63 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man78)

Rom Upgrade Version 2 (Fax Ring Issue)

Technical Bulletin

|

1

|

18.45 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man77)

Fax Recieving Trouble

Technical Bulletin

|

1

|

100.81 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man76)

PREVENTION OF PAPER JAM AT FUSER DUE TO LEAD EDGE ADJUSTMENT

Technical Bulletin

|

2

|

24.42 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man28)

CCE-1804 DESIGN CHANGE OF RSPF ORIGINAL GUIDE

Technical Bulletin

|

2

|

217.83 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man44)

CCE-1463 COUNTERMEASURE FOR F3-22 TROUBLE DUE TO THE BREAKAGE OF 2CS SENSOR HARNESS

Technical Bulletin

|

2

|

199.1 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man30)

CCE-1712 CHANGE OF RSPF UNIT PAPER FEED SHAFT

Technical Bulletin

|

2

|

246.82 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man31)

CCE-1686 ENHANCEMENT OF PAPER TRAY INSERTION

Technical Bulletin

|

1

|

76.83 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man32)

CCE-1652 CHANGE IN DESIGN OF PAPER FEED SHAFT

Technical Bulletin

|

2

|

659.27 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man33)

CCE-1622 Reduction Of Noise Caused When Opening SPF

Technical Bulletin

|

2

|

413.51 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man35)

Rom Upgrade CCE-1562

Technical Bulletin

|

3

|

299.25 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man43)

CCE1480 COUNTERMEASURE FOR JAM (POD1) DISPLAYED DUE TO DEFORMATION OF FUSING REAR ACTUATOR

Technical Bulletin

|

2

|

110.62 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man42)

CCE1474 ENHANCEMENT OF MFPC PWB

Technical Bulletin

|

2

|

133.99 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man41)

CCE1485 DISCONTINUANCE OF F UPPER CUSHION A

Technical Bulletin

|

2

|

55.08 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man40)

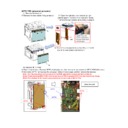

MFPC PWB replacement procedure

Technical Bulletin

|

4

|

903.41 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man39)

Starting Powder List (This list takes priority over information in Service Manuals).

Technical Bulletin

|

4

|

66.25 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man37)

Change in shape of open close lock pawl.

Technical Bulletin

|

3

|

97.28 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man36)

CCE-1501 CHANGE IN FERRITE CORE FOR FAX LINE CABLE

Technical Bulletin

|

2

|

79.44 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man34)

CHANGE ALONG WITH DISCONTINUATION OF MANUFACTURE OF AC INLET

Technical Bulletin

|

2

|

510.09 KB

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man26)

Rom Upgrade 1 Firmware V1.07.E1.00

Driver / Update

|

|

26.02 MB

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man25)

Rom Upgrade Version 2 01.07.E1.b0 (Fax Ring Issues)

Driver / Update

|

|

26.02 MB

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man24)

Combined MFP Firmware Version ICU 01.08.E1 - Production Run OCT 2013 - Release Bulletin To Follow

Driver / Update

|

|

26.07 MB

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man23)

Combined MFP Firmware Version ICU 01.10.E1

Driver / Update

|

|

26.06 MB

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man22)

CCE1301 02.02.E1.00 ROM Update (Bulletin Embedded)

Driver / Update

|

|

26.11 MB

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man21)

CCE-1317 OPEN SSL VULNERABILITY FIRMWARE RELEASE FOR FIELD SUPPORT VERSION V 0203E1b0 Bulletin embedded

Driver / Update

|

|

26.29 MB

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man20)

Combined MFP Firmware Version ICU 02.05.E1

Driver / Update

|

|

26.37 MB

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man19)

CCE-1459 Firmware update 02.06.E1

Driver / Update

|

|

35.21 MB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man18)

CCE1474 ENHANCEMENT OF MFPC PWB

Driver / Update

|

2

|

133.99 KB

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man17)

Bulletin to follow.

Driver / Update

|

|

35.12 MB

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man16)

Rom Upgrade 02.07.E1.00 (Refer to tech bulletin CCE-1562)

Driver / Update

|

|

35.12 MB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man2)

Handy Guide Feb 14

Handy Guide

|

34

|

2.7 MB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man3)

INFO REQUIRED FOR EE-PROM PROGRAMMING

Handy Guide

|

1

|

67.23 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR

EEPROM Programming Procedure

Handy Guide

|

4

|

772.27 KB

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man27)

Neo Training video (27 mins)

FAQ

|

|

143.64 MB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man79)

MSDS for MXC30GV-B Black Developer

Regulatory Data

|

5

|

43.31 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man80)

MSDS for MXC30GV-C Cyan Developer

Regulatory Data

|

4

|

40.17 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man81)

MSDS for MXC30GV-M Magenta Developer

Regulatory Data

|

4

|

40.29 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man82)

MSDS for MXC30GV-Y Yellow Developer

Regulatory Data

|

4

|

40.33 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man83)

MSDS for MXC30GT-B Black toner

Regulatory Data

|

5

|

42.76 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man84)

MSDS for MXC30GT-C Cyan toner

Regulatory Data

|

4

|

39.1 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man85)

MSDS for MXC30GT-M Magenta toner

Regulatory Data

|

4

|

39.12 KB

|

|

|

MX-C250 MX-C250E MX-C250F MX-C250FE MX-C250FR MX-C300F MX-C300W MX-C300WE MX-C300A MX-C300WR (serv.man86)

MSDS for MXC30GT-Y Yellow toner

Regulatory Data

|

4

|

39.22 KB

|