Read Sharp MX-4100N / MX-4101N / MX-5000N / MX-5001N (serv.man32) Service Manual online

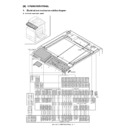

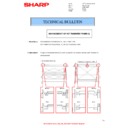

MX-4101N FUSER SECTION M – 1

MX-4101N

Service Manual

[M] FUSER SECTION

1. Electrical and mechanism relation diagram

P

ᴜᴶᴳᴉų

RWZ

R

CN2

B03P-VL-K

CN4

HL

PWB

PCU

P

WB

B03P-VL-RD

CN3

B08B-PASK

B2P3-VH

CN14

R

S

M-3pin(BK)

P

BK

WH

BL

P

D

F1B-20DE

E

CN13

R

S

M-2pin

P

B32B-PHDSS

R

S

M-2pin

P

R

S

M-4pin

P

P

S

M-2pin

R

B34B-PHDSS

RCZR

10PIN

TH_LM_IN

TH_EX2_IN

16

D-GND

/HL_PR

D-GND

D-GND

D-GND

2

HL_OUT_EX

INT24V1

N,C

N,C

N,C

1

N-HL(US)

1

HL_OUT_UM

8

12

INT24V1

D-GND

HL_OUT_US

4

6

N-HL(UM)

1

L-HL

U

3

3

N

-HL(EX)

2

N,C

TH_UMCS_IN

2

2

B-9

22

6

3

2

1

5

1

6

16

16

D-GND

18

D-GND

14

TH_UM_IN

18

HL_OUT_EX

HL_OUT_LM

6

N-HL(EX)

3

L-HL(LM)

2

N-HL(LM)

1

N-HL(US)

5

N-HL(UM)

L-HL

U

4

5

15

D-GND

2

19

19

15

11

14

13

13

D-GND

WEBD

11

D-GND

1

TH_UMCS_IN

10

WEBD

12

TH_EX1_IN

17

D-GND

TH_LM_IN

9

TH_EX2_IN

7

5

10

88

66

44

D-GND

A-9

A-1

A-10

5VN

A-1

A-2

11

13

17

D-GND

A-8

D-GND

4

1

D-GND

2

TH_EX1_IN

3

TH_EX2_IN

B-3

D-GND

1

TH_LM_IN

1

2

B-4

B-7

B-6

TH_UM_IN

1

1

3

2

1

2

TH_UMCS_IN

D-GND

7

5

6

3

1

L-HL(LM)

2

B-2

B-1

TH_UM_IN

TH_UM_IN

HL_OUT_UM

8

D-GND

B-8

B-7

12

14

14

TH_US_IN

D-GND

TH_EX1_IN

1

RCZR

9PIN

B-9

TH_LM_IN

A-7

D-GND

A-8

A-10

WEBD

A-9

3

77

9

9

A-5

A-4

A-6

A-3

5

1

1

2

5VN

D-GND

A-7

A-6

A-5

A-2

A-3

A-4

3

B-5

B-8

B-6

B-4

B-3

B-2

B-5

TH_EX2_IN

D-GND

D-GND

B-1

TH_UMCS_IN

4

3

N-HL(LM)

10

8

D-GND

HL_OUT_US

2

1

5VN

10

TH_EX1_IN

3

2

/HL_PR

HL_OUT_LM

12

TH_US_IN

4

TH_US_IN

3

2

4

2

D-GND

TH_US_IN

4

1

W

EBD

2D

-G

N

D

3

1

CN14 INT24V1 P-GND /FUM_CK

2

5

/FUM_D

29

FUM_LD

31

27

CN13

DF1B-26Pin

INT24V1

D-GND

32

31

19

19

WEB_M2out

18

WEB_M1out

18

P

SL-2Pin

R

2

WEB_M2out

2

1

WEB_M1out

1

R

SM-12Pin

P

/FUM_D

1

INT24V1

4

1

6

6

NC

4

5

5

FUM_LD

5

2

2

P-GND

3

3

/FUM_CK

WEBM

WEB-END

FUM

TH_UM

TH_LM

TH_US

TS SUB

TS MAIN

TS EX1

TH_EX1

TH_EX2

TS EX2

HL_EX2

HL_EX1

HL_UM

HL_LM

1

5

2

2

3

4

6

6

2

MX-4101N FUSER SECTION M – 2

2. Operational descriptions

A. Fusing unit drive

For driving the fusing unit, the drive power is transmitted from the

drive motor (FUM) through the connection gear to the upper heat

roller gear.

Driving by the drive motor (stepping motor) is performed according

to the control signal sent from the PCU.

drive motor (FUM) through the connection gear to the upper heat

roller gear.

Driving by the drive motor (stepping motor) is performed according

to the control signal sent from the PCU.

B. Heater lamp drive

The surface temperature of the heat roller detected by the ther-

mistor is sent to the PCU. When the temperature is lower than the

specified level, the heater lamp ON signal is sent from the PCU to

the heater lamp drive circuit on the HL PWB.

The power triac in the heater lamp drive circuit is turned on, and the

AC power is supplied to the heater lamp, lighting the lamp and

heating the heat roller.

To prepare for an abnormally high temperature of the heat roller,

the thermostat is provided for safety.

When the thermostat is opened, the power supply (AC line) to the

heater lamp is cut off.

mistor is sent to the PCU. When the temperature is lower than the

specified level, the heater lamp ON signal is sent from the PCU to

the heater lamp drive circuit on the HL PWB.

The power triac in the heater lamp drive circuit is turned on, and the

AC power is supplied to the heater lamp, lighting the lamp and

heating the heat roller.

To prepare for an abnormally high temperature of the heat roller,

the thermostat is provided for safety.

When the thermostat is opened, the power supply (AC line) to the

heater lamp is cut off.

C. Fusing operation

Color toner (Y,M,C,K) on paper is subject to heat and pressure to

be fused on paper.

At that time, color toner of Y, M, C, and K are mixed to reproduce

colors approximate to the document image colors.

The heater lamps are provided in the lower and the upper heat

roller to heat paper from the upper and the lower sides.

This is because paper must be heated both from the upper side

and from the lower side together in order to melt and fuse toner in

the four layers on the paper.

The upper and the lower heat rollers of silicon rubber are

employed.

This is because of the following reasons.

be fused on paper.

At that time, color toner of Y, M, C, and K are mixed to reproduce

colors approximate to the document image colors.

The heater lamps are provided in the lower and the upper heat

roller to heat paper from the upper and the lower sides.

This is because paper must be heated both from the upper side

and from the lower side together in order to melt and fuse toner in

the four layers on the paper.

The upper and the lower heat rollers of silicon rubber are

employed.

This is because of the following reasons.

1)

To increase the nip quantity. To increase the heating capacity

for paper.

for paper.

2)

By pressing the flexible roller, multi-layer toner can be fused

without deformation.

without deformation.

3)

An even pressure can be applied to rough surface of toner lay-

ers (multi-layer structure).

ers (multi-layer structure).

Signal name

Name

Function/Operation

FUM

Fusing motor

Drives the fusing unit.

HL_LM

Heater lamp lower main

Heats the fusing roller (pressing).

HL_UM

Heater lamp upper main

Heats the fusing roller (heating).

HL_EX1

Heater lamp external 1

Heats the fusing roller (heating). (External)

HL_EX2

Heater lamp external 2

Heats the fusing roller (heating). (External)

HLPCD

Fusing pressure release sensor Detects pressure release of the fusing roller.

TS MAIN

Thermostat (1)

Shuts conduction to the heater lamp when the temperature rises abnormally. [For the fusing roller (heating)]

TS EX1

Thermostat (2)

Shuts conduction to the heater lamp when the temperature rises abnormally. [For the fusing roller (heating)]

(External)

(External)

TS EX2

Thermostat (3)

When the temperature rises abnormally, conduction to the heater lamp is cut off.

[For the fusing roller (heating)] (External)

[For the fusing roller (heating)] (External)

TS SUB

Thermostat (4)

When the temperature rises abnormally, conduction to the heater lamp is cut off.

[For the fusing roller (pressing)] (External)

[For the fusing roller (pressing)] (External)

PRM

Fusing pressure release motor

Adjusts the fusing roller pressure.

TH_UM

Fusing temperature sensor (1)

Detects the surface temperature of the fusing roller (heating). (Center section)

TH_US

Fusing temperature sensor (2)

Detects the surface temperature of the fusing roller (heating). (Edge section)

TH_LM

Fusing temperature sensor (3)

Detects the surface temperature of the fusing roller (pressing).

TH_EX1

Fusing temperature sensor (4)

Detects the surface temperature of the heat roller (external).

TH_EX2

Fusing temperature sensor (5)

Detects the surface temperature of the heat roller (external).

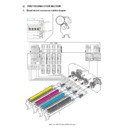

No.

Name

Function/Operation

1

Fusing roller (Heating)

Applies heat and pressure to toner on paper to fuse it on paper.

2

Upper separation pawl

Mechanically separates paper which was not naturally separated from the fusing roller (heating).

3

Fusing roller (Pressing)

Applies heat and pressure to toner on paper to fuse it on paper.

4

Transport roller 9 (Drive)

Transports paper from the fusing roller to the paper exit roller 1.

5

Web roller

Cleans the upper heat roller.

6

Lower separation pawl

Mechanically separates paper which was not naturally separated from the fusing roller (pressing).

FUM

PCU

MX-4101N FUSER SECTION M – 3

D. Automatic pressure release system

The upper and the lower heat rollers are normally pressed. When,

however, one of the following conditions is satisfied, they are

released from the pressure.

• When the machine shifts to the pre-heating mode.

• When the machine shifts to the auto power shut off mode.

• When the power switch of the operation panel is turned OFF.

• When the machine has been left in the ready state for 20 min-

however, one of the following conditions is satisfied, they are

released from the pressure.

• When the machine shifts to the pre-heating mode.

• When the machine shifts to the auto power shut off mode.

• When the power switch of the operation panel is turned OFF.

• When the machine has been left in the ready state for 20 min-

utes.

• When the envelope mode is used.

(1) Pressure release operation

The pressure release motor (PRM) rotates to drive the pressure

release lever of the fusing unit to the pressure release state via the

reduction gears (6 pcs.).

When 1710ms passes from operating the pressure release detec-

tion level and driving the pressure release sensor (HLPCD) to the

transmission state (L level), the pressure release motor stops to

complete the pressure release operation.

release lever of the fusing unit to the pressure release state via the

reduction gears (6 pcs.).

When 1710ms passes from operating the pressure release detec-

tion level and driving the pressure release sensor (HLPCD) to the

transmission state (L level), the pressure release motor stops to

complete the pressure release operation.

(2) Pressing operation

When an end use performs any operation or when the machine

receives a job signal, the pressure release motor rotates reversely

to dive the pressure release lever to the pressing state.

When 430ms passes from when the pressure release sensor

(HLPCD) is in the interruption state (H level), the pressure motor

stops to complete the pressing operation.

receives a job signal, the pressure release motor rotates reversely

to dive the pressure release lever to the pressing state.

When 430ms passes from when the pressure release sensor

(HLPCD) is in the interruption state (H level), the pressure motor

stops to complete the pressing operation.

NOTE: When turning OFF the main power switch of the machine,

be sure to turn OFF the power switch of the operation

panel and check to confirm that the LCD is turned OFF.

If the main power switch is turned OFF with the LCD dis-

played, the power is tu5ned off without completion of the

pressure release operation. This will deform the upper and

the lower heat rollers.

When, in addition, the fusing roller is installed again after

removing it, be sure to install it under the pressure release

state.

panel and check to confirm that the LCD is turned OFF.

If the main power switch is turned OFF with the LCD dis-

played, the power is tu5ned off without completion of the

pressure release operation. This will deform the upper and

the lower heat rollers.

When, in addition, the fusing roller is installed again after

removing it, be sure to install it under the pressure release

state.

E. Fusing temperature control

The temperature sensor is provided at the center and the edge sec-

tion of the upper heat roller and at the edge section of the lower

heat roller.

The heat roller temperature is detected by each temperature sen-

sor to control the heater lamp to maintain the temperature at the

specified level.

In addition, the fusing temperature is switched according to the kind

of paper.

tion of the upper heat roller and at the edge section of the lower

heat roller.

The heat roller temperature is detected by each temperature sen-

sor to control the heater lamp to maintain the temperature at the

specified level.

In addition, the fusing temperature is switched according to the kind

of paper.

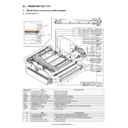

In the case of SW-A

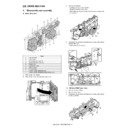

3. Disassembly and assembly

A. Fusing unit

1)

Open the right door.

Pressure release lever

Pressure release

motor (PRM)

motor (PRM)

Pressing condition

Pressure release

state

state

Mode

Paper

Upper

heater

lamp main

Upper

heater

external

Lower

heater

heater

lamp main

Ready

condition

Print mode

condition

Print mode

Black/White

plain paper

plain paper

170

220

125

Color plain

paper

paper

170

220

130

Thick paper

185

220

140

OHP

180

220

140

Envelope

200

220

140

Glossy paper

185

220

140

Parts

a

Upper thermostat

b

Lower thermostat

c

External thermostat

d

Upper heater lamp

e

Lower heater lamp

f

External heater lamp

g

Fusing cleaning roller / Fusing cleaning roller bearing

a

b

d

e

g

c

c

f

f

MX-4101N FUSER SECTION M – 4

2)

Remove the blue screw and the step screw. Release the lock

lever and remove the fusing unit.

lever and remove the fusing unit.

(1) Upper thermostat

1)

Remove the fusing unit.

2)

Remove the screw. Pull out the interface harness and remove

the fusing upper cover.

the fusing upper cover.

3)

Remove the screw, and remove the terminal. Remove the

upper thermostat.

* Install so that the caulked section of the terminal faces up.

upper thermostat.

* Install so that the caulked section of the terminal faces up.

(2) Lower thermostat

1)

Remove the fusing unit.

2)

Remove the screw, and remove the fusing lower cover.

3)

Remove the screw, and remove the terminal. Remove the

lower thermostat.

* Install so that the caulked section of the terminal faces

lower thermostat.

* Install so that the caulked section of the terminal faces

down.

(3) External thermostat

1)

Remove the fusing unit.

2)

Remove the fusing upper cover.

3)

Remove the screw, and remove the terminal. Remove the

external thermostat.

* Install so that the caulked section of the terminal faces up.

external thermostat.

* Install so that the caulked section of the terminal faces up.

2

1

1

1

3

2