Read Sharp MX-1800N (serv.man32) Service Manual online

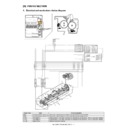

MX-1800N TRANSFER SECTION L – 1

MX-1800N

Service Manual

[L] TRANSFER SECTION

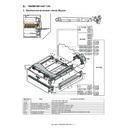

1. Electrical and mechanism relation diagram

Signal name

Name

Functions and operations

1TC_CMY

Color trasnfer high voltage signal

1TC_K

B/W transfer high voltage signal

1TNFD

Waste toner full detection switch

Waste toner full detection

1TUD_CL

Transfer belt separation CL detection

Color transfer roller position detection signal

1TUD_K

Transfer belt separation BK detection

B/W transfer roller position detection signal

1TURC

Primary transfer separation clutch

Transfer roller separation control clutch

2TC

Secondary transfer high voltage signal

DVMK

Developer drive motor (K)

Transfer unit drive motor (Used together with the B/W developing drive roller)

WTNM

Waste toner drive motor

Stirs waste toner.

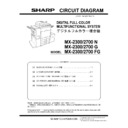

CN9

PHNR-3-H + BU03P-TR-P-H

B30B-PHDSS-B

CN1

CN34

2-TC

INT24V2

1

P-GND

2

CLR

/TC_CLK#

4

/TC_DATA#

3

/TC_LD#

5

/HV_REM#

6

B6P-PH-K-S

B40B-PADSS-B

B30B-PHDSS-B

CN1

B6P-PH-K-S

CN26

CN2

1TC_CL

3

HV_REM

7

MC_YMC

6

1TC_K

5

B32B-PHDSS-B

1TC_YMC

4

P-GND

2

INT24V2

1

B7P-PH-K-S

CN1

INT24V2

7

1TC-K

P-GND

6

1TC_YMC

4

1TC-CMY

1TC_K

3

MC_YMC

2

HV_REM

1

1TC_CL

5

B7P-PH-K-S

CN9

PHNR-3-H + BU03P-TR-P-H

B30B-PHDSS-B

HV_REM#

6

5

4

3

2

1

5

4

3

2

1

/HV_DATA#

/HV_CLK#

/HV_LD1#

/HV_LD1#

INT24V2

P-GND

/HV_CLK#

/HV_LD1#

HV_REM#

/HV_LD1#

HV_REM#

20

21

22

23

24

21

22

23

24

2

4

6

8

4

6

8

INT24V2

P-GND

/TC_CLK#

/TC_DATA#

2

1TUD_CL

11

1TUD_CL

1

2

1TUD_CL

1

3

3

5VLED

GND

9

13

12

14

14

5VLED

3

1

5VLED

D-GND

2

3

D-GND

5VLED

3

1TUD_K

1

D-GND

2

1

5VLED

2

1TUD_K

3

D-GND

2

1

3

1

3

5VLED

10

1TUD_K

D-GND

PCU PWB

2nd TC PWB

MC PWB

1st TC PWB

/TC_LD#

/HV_REM#

10

12

12

P-GND

/HV_DATA#

1TUD_CL

1TC_K

2TC

DVMK

1TURC

1TNFD

WTNM

1TC_CMY

R

SM18PIN

P

CN9

P

SL2PIN

R

1

1TNFD

1

2

17

D-GND

2

WTNM_1

1

WTNM_2

2

1

2

2

D-GND

1TNFD

WTNM_1

18

WTNM_2

3

1TNFD

3

4

D-GND

4

5

WTNM_1

5

6

WTNM_2

6

1TUD_K

CN12

PHNR-02-H + BU02P-TR-P-H

B32B-PHDSS-B

24V3

2

2

/1TURC

1

1

16

14

/1TURC

24V3

1

7

9

4

10

11

12

13

2

5

8

3

6

3

MX-1800N TRANSFER SECTION L – 2

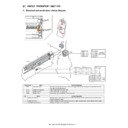

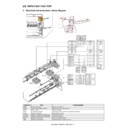

2. Operational descriptions

A. Outline

In this section, a high voltage is applied to transfer images to the

intermediate transfer belt and toner images on the intermediate

transfer belt are transferred to paper by the secondary transfer belt.

intermediate transfer belt and toner images on the intermediate

transfer belt are transferred to paper by the secondary transfer belt.

B. Primary (intermediate) transfer roller

separation mechanism and content

The primary transfer roller performs all pressure contact, all sepa-

ration, and only black contact depending on the operation mode.

When the roller separation clutch (1TURC) is turned ON, the trans-

fer cam rotates and the primary transfer link and the primary trans-

fer arm which is linked with the cam are shifted in the arrow

direction, performing separation of the roller.

ration, and only black contact depending on the operation mode.

When the roller separation clutch (1TURC) is turned ON, the trans-

fer cam rotates and the primary transfer link and the primary trans-

fer arm which is linked with the cam are shifted in the arrow

direction, performing separation of the roller.

The arm performs all pressure contact, all separation, and only

black contact.

black contact.

The primary transfer and the secondary transfer are driven together

with the black developing motor.

with the black developing motor.

No.

Name

Functions and operations

1

Intermediate transfer blade

Cleans residual toner on the intermediate transfer belt.

2

Intermediate transfer belt

Transfers toner on the OPC drum to form toner images on the belt.

3

Primary transfer roller

Transfers toner images on the OPC drum to the intermediate transfer belt.

4

Transfer drive roller

Drives the transfer belt.

5

Transfer follower roller

Transfer belt follower drive

6

Tension roller

Applies a tension to the transfer belt.

7

Roller cleaning brush

Cleans the back surface of the transfer belt.

8

Y auxiliary roller

Retaining the belt position by separation of the Y transfer roller

9

Registration backup roller

Retaining the belt position in the process control and the registration section.

10

Secondary transfer belt

Transfers toner images on the intermediate transfer belt to paper.

11

Secondary transfer roller

Transfers toner images on the intermediate transfer belt to paper.

12

Secondary belt transfer roller

Drives the transfer belt.

13

Secondary belt tension roller

Applies a proper tension to the transfer belt.

1TUD_CL

1TUD_K

All pressure contact

ON

OFF

All separation

OFF

ON

Only black contact

OFF

OFF

All pressure contact

Only black pressure contact

All separation

MX-1800N TRANSFER SECTION L – 3

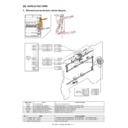

3. Disassembly and assembly

A. Primary transfer

(1) Primary transfer unit

1) Open the front cover.

2)

Open the right door unit.

3)

Loosen the blue screw.

4)

Turn the blue screw (A) counterclockwise. Making sure that

the lock is released (B), open and then pull out the drum posi-

tioning unit.

* Failure to complete this step may damage the intermediate

the lock is released (B), open and then pull out the drum posi-

tioning unit.

* Failure to complete this step may damage the intermediate

transfer belt.

5)

Hold the specified position, and remove the primary transfer

unit.

unit.

(NOTE)

When the transfer belt tension of the primary transfer unit is

released manually, turn on the power again after completion of

the work. (Power OFF-ON) This procedure initializes the trans-

fer roller to return it to the home position.

When the transfer belt tension of the primary transfer unit is

released manually, turn on the power again after completion of

the work. (Power OFF-ON) This procedure initializes the trans-

fer roller to return it to the home position.

Unit

Parts

Maintenance

(1)

Primary

transfer unit

transfer unit

a

Intermediate transfer belt

b

Primary transfer blade

c

Primary transfer coat roller

{

d

Primary transfer conduction

collar

collar

e

Y auxiliary roller

{

f

Belt drive gear

g

Transfer drive roller

{

h

Transfer follower roller

{

i

Tension roller

{

j

Roller cleaning brush

k

Registration backup roller

l

Cleaner seal

m

Cleaner seal R

n

Transfer toner reception seal

o

TC roller bearing

(2)

Others

a

Transfer belt separation CL

detection

detection

b

Transfer belt separation BK

detection

detection

(1)-d

(1)-k

(1)-f

(1)-b

(1)-n

(1)

(1)-i

(1)-h

(1)-a

(2)-a

(2)-b

(1)-e

(1)-c

(1)-g

(1)-j

(1)-l

(1)-m

A

B

MX-1800N TRANSFER SECTION L – 4

a. Intermediate transfer belt

* Do not replace the belt, and blade separately. When any of the

* Do not replace the belt, and blade separately. When any of the

three parts needs to be replaced, replace the other two parts as

well.

well.

* When replacing the belt, be sure to apply titanium hydroxide and

strontium titanate according to the instructions.

1) Remove the primary trasnfer unit.

2) Remove the transfer guide plate left unit.

3) Remove the parts.

2) Remove the transfer guide plate left unit.

3) Remove the parts.

4) Fold the CL section of the transfer frame and remove the inter-

mediate transfer belt.

* When installing, set the lot number inside the belt to the front

side.

[Precautions for installation]

When replacing the belt, make sure not to scratch or fold it.

Do not touch the surface of the belt with bare hands.

(Applying titanium hydroxide)

* Titanium hydroxide is fine powder, and may disperse when

When replacing the belt, make sure not to scratch or fold it.

Do not touch the surface of the belt with bare hands.

(Applying titanium hydroxide)

* Titanium hydroxide is fine powder, and may disperse when

removing from the bag. To prevent against dispersion, handle the

bag of titanium hydroxide at a lower position.

bag of titanium hydroxide at a lower position.

* Pushing the bag lightly against the belt provides sufficient appli-

cation of titanium hydroxide. Lift the bag from the application sur-

face by 5 mm or less.

face by 5 mm or less.

* Apply titanium hydroxide before installing the cleaner unit.

1)

Install the primary transfer UN with its backside facing upward

and remove the cleaner frame UN.

and remove the cleaner frame UN.

2)

Apply titanium hydroxide to the belt within approx. 15 cm from

the driving roller.

the driving roller.

3)

Rotate the belt by amount 10 cm to move the application part

to the surface.

* Till the applied powder reaches the cleaner installation loca-

to the surface.

* Till the applied powder reaches the cleaner installation loca-

tion.

4)

Mount the cleaner frame UN on the primary transfer UN.

5)

Apply titanium hydroxide to the belt.

* Apply titanium hydroxide to the belt 40 times (10 times in lat-

* Apply titanium hydroxide to the belt 40 times (10 times in lat-

itudinal direction x 4 times in longitudinal direction) for 4

faces (making two circuits of the belt).

faces (making two circuits of the belt).

* Repeat half-around application and half-around rotation

each 4 times.

* Apply titanium hydroxide not to produce bias.

1

2

12345

AB-67

15cm

Driving roller