Read Sharp MX-1800N (serv.man25) Service Manual online

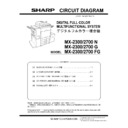

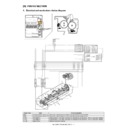

MX-1800N TRAY PAPER FEED SECTION E – 1

MX-1800N

Service Manual

[E] TRAY PAPER FEED SECTION

1. Electrical and mechanism relation diagram

PHNR-12-H+

P

DF1B-24p

S

CN6

BU12P-TR-P-H

B24B-PHDSS-B

CN4

S4P-PH-K-S

S4P-PH-K-S

PHNR-9-H+

BU09P-TR-P-H

B30B-PHDSS-B

5VNPD

3

D-GND

1

2

C

PED2

14

CPWD22

14

CPWD22

24

4

6

10

12

CPWD21

12

10

CSPD2

4

CLUD2

20

22

24

2

19

21

23

18

7

16

17

9

11

13

15

22

CSS23

6

CPED2

24

CSS24

2

CPFD2

18

CSS21

20

CSS22

21

CSS13

23

CSS14

17

CSS11

19

CSS12

15

CSS1

16

CSS2

11

CPWD11

13

CPWD12

7

DSW_R

9

CSPD1

18

CSS24

22

CPWD21

6

CPED2

8

CSPD2

4

CLUD2

17

CSS13

13

CSS11

15

CSS12

11

CSS1

10

CSS2

7

DSW_R

9

CSPD1

2

CPFD2

19

CSS14

12

CSS21

14

CSS22

16

CSS23

21

CPWD11

23

CPWD12

5VNPD

26

11

D-GND

9

D-GND

2

18

5VN

2

1

5VNPD

5VNPD

23

19

D-GND

3

5VN

2

0

D-GND

1

D-GND

D-GND

5

5VNPD

22

D-GND

8

D-GND

6

5VN

24

D-GND

7

10

11

12

D-GND

1

2

3

D-GND

4

5VNPD

5VNPD

10

7

D-GND

6

3

4

5

D-GND

CPED2

CPFD2

CLUD2

CSPD1

5VN

2

8

9

D-GND

1

1

3

9

2

5VN

3

1

2

D-GND

1

D-GND

1

D

-GND

3

D-GND

5VNPD

1

2

C

SPD2

D-GND

DSW_R

5VN

D-GND

3

2

1

D-GND

CPFD1

5VN

D-GND

6

8

7

5

4

12

4

9

1

D-GND

3

5

6

11

CPED1

5VNPD

CLUD1

2

10

9

5VNPD

5VN

3

CPFD2

2

1

2

3

D-GND

CPED1

5VNPD

1

2

D-GND

CPFD1

7

1

CPFD1

3

CLUD1

1

3

1

CPFD1

8

5

CPED1

5

3

CLUD1

5

CPED1

6

8

7

DRIVER MAIN PWB

5VNPD

5

4

5VNPD

5VNPD

25

PCU

2

5VN

3

D-GND

1

2

DSW_R

CSS1

CSS2

5VNPD

3

D-GND

1

2C

L

U

D

2

1

2

3

D-GND

CLUD1

5VNPD

CN17

B7P-PH-K-S

PHNR-2-H

BU02P-TR-P-H

PHNR-2-H

BU02P-TR-P-H

PHNR-2-H

BU02P-TR-P-H

R

SM18P

P

B32B-PHDSS-B

CN9

B2P-PH-K-S

3

INT24V2

B3P-PH-K-S

B2P-PH-K-S

P-GND

8

/CLUM2

/CPUC1

6

/CLUM1

14

15

15

/CLUM2

16

9

24V3

12

24V3

11

/CPFC

10

2

CPFM_LD

8

24V3

8

5

7

/CPFC

7

P-GND

4

/CPFM_CK

/CPFM_D

5

3

/CPFM_CK

3

4

/CPFM_D

4

5

CPFM_LD

9

/CPUC1

9

24V3

10

10

P-GND

/CLUM1

P-GND

14

15

15

16

7

P-GND

13

14

13

11

/CPUC2

24V3

2

1

2

1

/CPUC2

11

24V3

12

1

INT24V2

1

1

2

P-GND

2

12

13

2

/CPUC1

24V3

/CPFC

1

2

24V3

1

1

2

2

/CPUC2

24V3

1

1

2

P-GND

/CLUM2

1

2

P-GND

/CLUM1

1

2

3

4

5

6

7

INT24V2

P-GND

FG-OUT

/CPFM_CK

/CPFM_D

CPFM_LD

5V

PCU PWB

AC PWB

CPED1

1

2

4

CLUD1

CLUD2

CPFD1

DSW_R

CPFM CPUC1

CPFC

CLUM1

CLUM2

CPUC2

CPFD2

CPED2

CSS2

CSPD2

CSS1

CSPD1

3

5

6

7

8

10

9

11

11

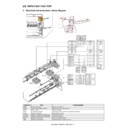

MX-1800N TRAY PAPER FEED SECTION E – 2

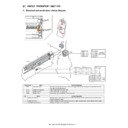

Signal name

Name

Function/Operation

CLUD1

Tray 1 upper limit detection (Lift HP detection)

Tray 1 upper limit detection

CLUD2

Tray 2 upper limit detection (Lift HP detection)

Tray 2 upper limit detection

CLUM1

Paper tray lift-up motor (Paper feed tray 1)

Drives the paper tray lift plate.

CLUM2

Paper tray lift-up motor (Paper feed tray 2)

Drives the paper tray lift plate.

CPED 1

Tray 1 paper empty detection

Tray 1 paper empty detection

CPED 2

Tray 2 paper empty detection

Tray 2 paper empty detection

CPFC

Tray vertical transport clutch

CPFD1

Tray 1 transport detection (Paper entry detection)

Tray 1 paper pass detection

CPFD2

Tray 2 transport detection (Paper entry detection)

Tray2 paper pass detection

CPFM

Paper feed motor

Paper feed section drive

CPUC1

Paper feed clutch (Paper feed tray 1)

Controls the paper feed tray section roller ON/OFF.

CPUC2

Paper feed clutch (Paper feed tray 2)

Controls the paper feed tray section roller ON/OFF.

CSPD1

Tray 1 paper remaining quantity detection

Tray 1 paper remaining quantity detection

CSPD2

Tray 2 paper remaining quantity detection

Tray 2 paper remaining quantity detection

CSS1

Tray 1 presence detection

Detects the presence of the tray 1

CSS2

Tray 2 presence detection

Detects the presence of the tray 2

DSW_C

Tray 1, 2 transfer cover open/close detection

Detects opening of the tray 1, 2 transport cover.

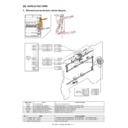

No.

Name

Function/Operation

1

Paper feed roller (No.1 paper feed tray)

Feeds paper to the paper transport section.

2

Paper pickup roller (No. 1 paper feed tray)

Feeds paper to the paper feed roller.

3

Separation roller (No. 1 paper feed tray)

Separates paper to prevent Double Feed.

4

Torque limiter

A certain level of resistance force is supplied to the rotation of the separation

roller to prevent double feed.

roller to prevent double feed.

5

Paper feed roller (No. 1 paper feed tray)

Feeds paper to the paper transport section.

6

Paper pickup roller (No. 2 paper feed tray)

Feeds paper to the paper feed roller.

7

Separation roller (No. 2 paper feed tray)

Separates paper to prevent Double Feed.

8

Transport roller 4 (Drive)

Transports the paper transported from the transport roller 1 and paper feed roller

(No. 2 paper feed tray) to the transport roller 7.

(No. 2 paper feed tray) to the transport roller 7.

9

Transport roller 5 (Drive)

Transports the paper fed from the paper tray 1 to the transport roller 7.

10

Transport roller 7 (Drive)

Transports the paper fed from the paper feed tray 1, 2 or 3, 4 to the transport

roller 8.

roller 8.

11

Rotation plate

Lifts up the paper to keep the paper feed position.

MX-1800N TRAY PAPER FEED SECTION E – 3

2. Operational descriptions

A. Preliminary operation before paper feed

• When the paper is set and the paper feed tray is inserted, the

pickup roller moves down and the paper feed tray sensor turns

ON.

ON.

• The lift-up motor operates to lift the rotating plate.

• The paper upper limit sensor turns on to stop the rotating plate at

• The paper upper limit sensor turns on to stop the rotating plate at

the specified position.

B. Paper feed operation

• When copy/print operation is started, the motor and the clutch

are turned ON and the pickup roller is rotated in the paper pickup

timing to feed paper.

timing to feed paper.

• At the same time, the paper feed roller rotates to feed paper to

the transport section. At that time, the separation roller rotates to

prevent against double feed of paper.

prevent against double feed of paper.

C. Remaining paper detection

• Remaining paper detection is performed according to four

stages, i.e. three stages with paper and one stage with no paper,

and the result is displayed.

and the result is displayed.

D. Remaining paper detection method

• The number of remaining sheets is determined according to the

number of times the remaining paper sensor changes from the

time the paper feed tray starts lifting up to the time when the

upper detection sensor comes ON.

time the paper feed tray starts lifting up to the time when the

upper detection sensor comes ON.

The no-paper detection sensor detects

the state of no remaining paper.

the state of no remaining paper.

1/3 Field

Sensor logic: Low

Sensor logic: Low

2/3 Field

Sensor logic: Hi

Sensor logic: Hi

3/3 Field

Sensor logic: Low

Sensor logic: Low

During no-paper detection

Remaining paper 1/3 position

Remaining paper 2/3 position

Remaining paper 1/3 position

Turn plate

CPED

(paper sensor)

(paper sensor)

Remaining Paper

Detection Actuator

Detection Actuator

CSPD

(remaining paper detection)

(remaining paper detection)

(Figure showing state transition of the remaining paper detection sensor during tray elevation and

changes in status according to the number of remaining sheets)

MX-1800N TRAY PAPER FEED SECTION E – 4

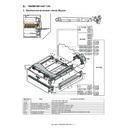

3. Disassembly and assembly

A. Tray paper feed section

(1) Remove the tray paper feed unit 1 and 2.

1)

Remove the right cabinet front.

2)

Remove the tray 1 and 2.

3)

Remove the right lower door unit.

4)

Remove the paper feed movable PG lower.

5)

Remove the paper feed unit 1, 2.

Unit

Parts

Maintenance

(1)

Tray paper

feed unit 1, 2

feed unit 1, 2

a

Paper pickup roller

{

b

Paper feed roller

{

c

Separation roller

{

d

Tray 1 transport cover

detection

detection

e

Transport roller 7 (Drive)

{

f

Transport roller 4 (Drive)

{

g

Torque limiter

h

Tray 1, 2 paper presence

detection

detection

i

Tray 1, 2 upper limit detection

j

Tray 1, 2 transport detection

k

Transport roller 5 (Drive)

{

(2)

Others

a

Tray 1, 2 paper remaining

quantity detection

quantity detection

b

Tray 1, 2 presence detection

(1)

(1)

(1)-a

(1)-b

(1)-c

(1)-j

(1)-g

(1)-e

(1)-d

(1)-k

(1)-a

(1)-h

(1)-i

(1)-c

(1)-b

(1)-j

(1)-g

(1)-f

(1)-h

(1)-i

(2)-b

(2)-a

1

2