Read Sharp AR-M351U / AR-M451U (serv.man14) Service Manual online

AR-M351U/M451U, AR-M355U/M455U MAINTENANCE AND DETAILS OF EACH SECTION 7 - 43

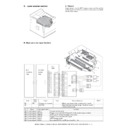

5. Laser scanner section

A. General

Image data sent from the MFP (image process circuit) through the

mother board and PCU are converted into laser beams to radiate

onto the drum surface.

mother board and PCU are converted into laser beams to radiate

onto the drum surface.

B. Major parts and signal functions

PCU

PWB

MOTHER

BOARD

PWB

MFP

CONTROL

PWB

CN2

CN2

CN1

26

GND

13

BUR_PR

MSW_MON

10

19

GND

16

25

DTR_PCU

22

28

9

RES_PCU

15

GND

DSR_PCU

12

21 RXD_PCU

18

27

GND

24

30

DTEN

GND

11 GND2

GND

8

17

HSYNC

TXD_PCU

14

23

POF

20

29

VIDEO1

VIDEO0

GND

SLD30R-1

+12V2

PCU_VCCW

5

7

6

3

+5V1

+5V2

+5V2

+5V2

+5V2

LSU

GND2

8

+24V1

+24V1

PMCLK\

START\

GND2

S11B-PH-K-S

CN2

CN1

VFM1\

1 GND2

+24V1

1

3

2

3

2

PHNR-03-H+BU03P-TR-P-H

PMCLK

3 START\

READY

PHR-5

1

2

5

4 GND2

+24V1

VFM1

+24V1

VFM1\

GND2

VFM1\

+5V2

GND2

4

2

GND2

1

3

S4B-PH-K-S

CN3

SYNC\

GND2

1

2

3

4

SYNC\

GND2

1 GND2

+24V1

3

2

3

2

1

PHNR-03-H+BU03P-TR-P-H

VFM1\

11

1

2

3

4

5

6

7

9

10

RD

RD

RD

BR

BR

BR

BR

BR

GY

GY

GY

RD

RD

BR

BR

GY

GY

VFM1

POWER SOURCE

SECTION

SECTION

B4B-PH-K-S

1

2

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

S32B-PHDSS-B

/VFM1

GND2

VIDEO

LSU_S/H

GND2

/LDON

/VIDEO

/SYNC

GND2

3

4

+5V2

/PMCLK

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

CN16

+5V LD

GND2

23

24

/READY

/START

TEST

25

GND2

S32B-PHDSS-B

/VFM1

26

VRB

GND2

+5V2

GND2

+24V1

+24V1

GND2

GND2

27

28

29

30

31

32

GND2

GND2

GND2

GND2

45 sheets (35 sheets)

/START

/PMCLK

+5V2

GND2

/SYNC

GND2

/VIDEO

/LDON

GND2

+24V1

TEST

VIDEO

GND2

/VFM1

GND2

GND2

+5V LD

GND2

GND2

GND2

GND2

GND2

VRB

GND2

GND2

+24V1

/READY

+5V2

/VFM1

10

9

8

7

6

5

4

READY(READY\)

45 sheets (35 sheets)

+5V2

BD

BR

LB

BL

BR

GY

GY

GY

GY

GY

GY

GY

GY

GY

GY

GY

GY

BR

BR

BR

BR

LBR

BR

BR

BR

BR

BR

BR

BL

BL

BL

RD

RD

3

1

TEST3

TEST2

31

32

2

1

TEST2

TEST3

GY

BR

BR

BR

BR

LSU_S/H

4

2

1

+5V2

+12V1

GND

PM

1

2

6

9

8

7

3

4

10

5

Code

Signal

name

Name

Type

Function/Operation

NOTE

PM

PM

Polygon mirror (motor)

Reflects laser beams at the constant rotation speed.

BD

BD PWB

Detects the laser scan start timing. This device is used

to detect a laser trouble.

to detect a laser trouble.

No.

Name

Code, signal name

Function

RW

Control signal

+5VLD

5V power for laser diode

RW

Control signal

/READY

Polygon mirror motor READY signal ("L" in the constant speed rotation)

RW

Control signal

/PMCLK

Clock signal for driving the polygon mirror motor

RW

Control signal

/START

Polygon mirror motor drive start signal

RW

Control signal

/VIDEO

VIDEO (Image signal)

RW

Control signal

/SYNC

Sync signal (SYNC) from BD, sync signal for 1 line

AR-M351U/M451U, AR-M355U/M455U MAINTENANCE AND DETAILS OF EACH SECTION 7 - 44

C. Operational descriptions

[Laser optical path]

∗

The LSU must not be disassembled in the market.

(1) Polygon motor

(2) Outline of LSU specifications

D. Maintenance and parts replacement

a-1. LSU

1) Remove the screw, and remove the right cabinet.

2) Remove the screw, and remove the right noise cover.

3) Remove the connector, and remove the screw.

No.

Name

Function

1

Laser control PWB

Controls laser beam flashing and the output value.

2

Cylindrical lens

Converges laser beams to focus.

3

Incidence reflection mirror

Assures the optical path for laser beams.

4

No. 1 mirror

Assures the optical path for laser beams.

5

f

θ

lens 1

Deflects laser beams so that the laser scan speeds on the both ends of the drum and that at the

center of the drum are the same.

center of the drum are the same.

6

f

θ

lens 2

7

BD PWB

Detects the timing of laser scan start. This device is used to detect a laser trouble.

8

No. 2 mirror

Converges laser beams to focus.

9

Plane lens

Assures the optical path for laser beams.

10

Convergence lens for BD

Converges laser beams onto the BD PWB.

Model

Number

of mirrors

RPM

Bearing

31/35PPM

14

17000RPM

OIL

Superior in

silence.

silence.

45PPM

14

22000RPM

OIL

Effective scan width:

297mm

Resolution:

600dpi

Beam diameter:

Main scan = 60 - 85

µ

m

Sub scan = 75 - 110

µ

m

Laser power:

0.23±0.01mW (45 PPM)

0.19±0.01mW (35 PPM)

0.19±0.01mW (35 PPM)

LD wave length:

770 - 795nm

No.

Unit

Parts

a

1

LSU

a-1

AR-M351U/M451U, AR-M355U/M455U MAINTENANCE AND DETAILS OF EACH SECTION 7 - 45

4) Remove the screw, and remove the rear cabinet.

5) Remove the connector, the screw, and the angle. Remove the

snap band.

∗

Do not disconnect the LSU side.

6) Pull out the No. 1 paper feed tray unit, and push up and

remove the front door.

7) Release the lock, and pull out the left door. Remove the

screw, and remove the front cover right.

8) Remove the screw, and remove the main switch mounting

plate.

9) Remove the power unit.

10) Remove the connector and the screw, and remove the duct

holding cover.

11) Remove the screw, and remove the LSU.

AR-M351U/M451U, AR-M355U/M455U MAINTENANCE AND DETAILS OF EACH SECTION 7 - 46

6. Scanner section

A. General

There are following three methods of scanning documents in this

machine.

machine.

a. Place a document on the table glass. The copy lamp unit is

operated to radiate copy lamp light onto the document, scan-

ning the document with the CCD.

ning the document with the CCD.

b. The SPF feeds a document. The copy lamp light is radiated

onto the document which is stopped at the specified position

and the document is scanned by the CCD.

and the document is scanned by the CCD.

c. The SPF feed a document. The LED light of the CIS unit which

is attached to the SPF is radiated to the back of the document,

and the document is scanned by the CIS.

and the document is scanned by the CIS.