Read Sharp AR-M351U / AR-M451U (serv.man12) Service Manual online

AR-M351U/M451U, AR-M355U/M455U MAINTENANCE AND DETAILS OF EACH SECTION 7 - 21

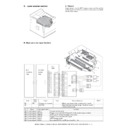

2. Fusing section

A. General

This section fused toner (which is transferred onto paper in the

transfer section) onto paper by heat and pressure of the fusing

roller.

transfer section) onto paper by heat and pressure of the fusing

roller.

B. Major parts and signal functions

Copy

Paper

exit

exit

Fusing roller

(Heating)

(Heating)

Power/

Filter PWB

Filter PWB

Main

motor

motor

Paper exit

roller

roller

Heater lamps

(2 pcs.)

(2 pcs.)

Fusing roller

(Pressing)

(Pressing)

Cleaning

roller

roller

Fusing

Rth1

MM

AC/DC

PWB

2

1

B-1

BR

HL2

2

3

RTH2

B-5

GY

2

BR

Rth2

HLTS

B-4

B-3

L2

1

2

GY

3

B-3

2

HL1

GND2

GND2

B-1

GY

4

4

HL2

3

BR

4

B-2

4

1

RTH1

3

BR

B-4

B03P-VL

CN1

3

1

GY

1

SMP-04V-NC+SMR-04V-N

1

HL2

GY

2

3

3

VLP-03V+VLR-03V

WH

HL1

2

1

L2

WH

BK

7

MSW MON

6

2

HLCNT1

CN2

5

3

(NC)

1

4

HLPR

HLCNT2

+24VPR

B7B-PH-K-S

DCCNT/

+24V1

12

+24V3

GND2

+3.3V1

6

GY

GY

CN5

7

BR

RD

RD

OR

GY

FW

3

GND2

+5V2

+24V2

GND2

1

11

GND2

+3.3V1

OR

GY

B12P-HL-A

2

9

+5V1

4

10

8

5

BR

BR

GY

BR

GY

BR

OR

GY

RD

RD

GY

GY

BR

BR

BR

RD

BR

OR

PCU

PWB

PWB

15

GND2

(NC)

CN14

2

14

+5V2

13

(NC)

6

11

10

8

RTH1

4

HLPR

6

4

+3.3V1

RTH2

1

3

GND

HLCNT1

GND

HLCNT2

MSW MON

9

GND2

12

+5V2

5

+24V1

+3.3V1

FW

5

7

16

CN17

+24VPR

GND2

8

GND2

3

+24V2

9

7

1

+12V2

BUP_PR

B16B-PH-K-S

GND2

2

B9P-VH

B-2

B-5

09R-RWZV-K2GGP4+CZHR-05V-S

REACTOR

PWB

PWB

200V ONLY

TAIWAN ONLY

WH

HL-L

3

2

1

HL-1N

HL-2N

WH

BR

WH

BK

BK

HL1

L2R

L

#187(BK)

#187(BK)

(NC)

2

1

L2

CN2

B03P-VL

B03P-VL

(NC)

L2R

3

4

CN1

B2P4-VH

B2P4-VH

BK

BK

SRA-51T-4

SRA-51T-4

2

L2

1

HL2

3

B03P-VL

CN1

HL1

1

HL2

GY

2

3

3

VLP-03V+VLR-03V

WH

HL1

2

1

L2

WH

BK

DSW-F

MM-T

GND2

+5V2

GND2

MM\

9604S-08C

1

2

3

4

5

6

7

8

CN9

DSW-F

GND2

DSW-L

MM-T

GND1

+5V2

GND2

MM\

DSW-L

GND1

8FE-ST-VK-N

8

7

6

5

4

3

2

1

7

8

9

1

9

3

4

6

5

7,8

2

10

FILTER PWB

L2in

1

2

3

L2out

(NC)

BK

BK

CN1

B03P-VL(RD)

B03P-VL(RD)

AR-M351U/M451U, AR-M355U/M455U MAINTENANCE AND DETAILS OF EACH SECTION 7 - 22

C. Operational descriptions

(1) Fusing unit drive

To drive the fusing unit, the drive power is transmitted from the

drive motor (MM) through the connection gear to the upper heat

roller gear.

drive motor (MM) through the connection gear to the upper heat

roller gear.

The drive motor DC brushless motor is driven according to the

control signal sent from the PCU.

control signal sent from the PCU.

(2) Heater lamp drive

The surface temperature of the heat roller detected by the ther-

mistor is sent to the PCU.

mistor is sent to the PCU.

When the temperature is lower than the specified level, the heater

lamp lighting signal is sent from the PCU to the heater lamp drive

circuit in the sub power PWB.

lamp lighting signal is sent from the PCU to the heater lamp drive

circuit in the sub power PWB.

The power triac in the heater lamp drive circuit is turned on, and

the AC power is supplied to the heater lamp, lighting the lamp and

heating the heat roller.

the AC power is supplied to the heater lamp, lighting the lamp and

heating the heat roller.

To prepare for an abnormally high temperature of the heat roller,

the thermostat is provided for safety.

the thermostat is provided for safety.

When the thermostat is opened, power supply (AC line) to the

heater lamp is cut off.

heater lamp is cut off.

(3) Fusing operation

Toner on paper is heated and pressed to be fused by the heat

roller.

roller.

Code

Signal

name

Name

Type

Function/Operation

Active

condition

Note

RTH1

RTH1

Fusing temperature

sensor (1)

sensor (1)

Thermistor Detects the surface temperature of the fusing roller

(heating). (Center section)

Analog input

RTH2

RTH2

Fusing temperature

sensor (2)

sensor (2)

Thermistor Detects the surface temperature of the fusing roller

(heating). (Edge section)

Analog input

HLTS

HLTS

Thermostat (1)

Shuts conduction to the heater lamp when the

temperature rises abnormally. [For the fusing roller

(heating)]

temperature rises abnormally. [For the fusing roller

(heating)]

HL1

HL1

Heater lamp (1)

Heats the fusing roller (heating).

HL2

HL2

Heater lamp (2)

Heats the fusing roller (heating).

MM

MM

Main motor

Drives the fusing unit.

1

Heater lamp 1

Generates heat and transmits heat to the heat roller. The temperature is controlled by the

thermistor. (Temperature control is made mainly on the center.)

thermistor. (Temperature control is made mainly on the center.)

2

Heater lamp 2

Generates heat and transmits heat to the heat roller. The temperature is controlled by the

thermistor. (Temperature control is made mainly on both sides.)

thermistor. (Temperature control is made mainly on both sides.)

3

Upper heat roller

Transmits heat to melt toner on paper and fuse toner by means of a pressure with the lower heat

roller.

roller.

4

Lower heat roller

Fuses toner on paper by means of a pressure with the upper heat roller.

To improve fusing capability, the diameter is greater than the conventional ones.

(ø30mm

To improve fusing capability, the diameter is greater than the conventional ones.

(ø30mm

→

ø40mm)

5

Fusing upper separation pawl

Prevents winding of paper around the upper heat roller.

6

Fusing lower separation pawl

Prevents winding of paper around the lower heat roller.

7

Thermistor (Center)

Detects the surface temperature of the upper heat roller.

(On/off of heater lamp 1 is controlled according to the detected temperature.)

(On/off of heater lamp 1 is controlled according to the detected temperature.)

8

Thermistor (Side)

Detects the surface temperature of the upper heat roller.

(On/off of heater lamp 2 is controlled according to the detected temperature.)

(On/off of heater lamp 2 is controlled according to the detected temperature.)

9

Thermostat

When an abnormal temperature of the upper heat roller is detected, the heater lamp power is

interrupted.

To supply power again, press the switch on the top.

interrupted.

To supply power again, press the switch on the top.

10

Cleaning roller

Cleans toner on the lower heat roller. The blast process is employed.

MM

PCU

Fusing roller (Heating)

HL2

HL1

---------

Fusing roller (Pressing)

Paper exit

AR-M351U/M451U, AR-M355U/M455U MAINTENANCE AND DETAILS OF EACH SECTION 7 - 23

The fusing heat roller (heating) is provided with two heater lamps,

which heat the fusing roller to fuse toner onto paper.

which heat the fusing roller to fuse toner onto paper.

The fusing rollers (pressing) are of silicon rubber because of the

following reasons and purpose.

following reasons and purpose.

1) Paper is separated upward. (Since the fusing roller (heating) is

of higher hardness, the fusing roller (pressing) is deformed to

separate paper upward.)

separate paper upward.)

2) The nip quantity is increased to increase heat capacity for

paper.

3) By pressing paper with the flexible roller, toner is fused without

deformation.

(4) Fusing temperature control

The temperature sensor is provided at the center of the fusing

roller (heating).

roller (heating).

The roller temperature is detected by the installed temperature

sensor, and the heater lamp is controlled so that the temperature

is maintained at the specified level.

sensor, and the heater lamp is controlled so that the temperature

is maintained at the specified level.

In addition, the fusing temperature is switched according to the

kind of paper.

kind of paper.

(5) Cleaning roller

The fusing section cleaning roller of this machine is made of the

blast process.

1) Remaining toner attaches to the upper heat roller.

1) Remaining toner attaches to the upper heat roller.

2) Due to coating and the temperature characteristics of the

upper heat roller, toner is not attached to the upper heat roller

but to the lower heat roller.

but to the lower heat roller.

3) Remaining toner on the lower heat roller is further attached to

the cleaning roller due to the temperature characteristics and

the difference in roughness of surfaces of the rollers.

the difference in roughness of surfaces of the rollers.

4) Remaining toner attached to the cleaning roller is accumulated

until the roller is replaced.

D. Maintenance and parts replacement

(1) Maintenance list

Mode

Fusing roller

AR-M351U/

M355U

AR-M451U/

M455U

Ready condition

print mode

print mode

Plain paper

190°C

190°C

Heavy Paper

190°C

190°C

Postcard

190°C

190°C

Envelope

190°C

190°C

Pre-heat

150°C

150°C

Unit name

No.

Part name

When

calling

100K

200K

300K

400K

500K

600K

700K

800K

Remark

Fusing

section

1

Upper heat roller

✕

✕

▲

✕

▲

✕

▲

✕

▲

2

Lower heat roller

✕

✕

▲

✕

▲

✕

▲

✕

▲

3

Upper separation pawl

❍

❍

▲

❍

▲

❍

▲

❍

▲

4

Lower separation pawl

❍

❍

▲

❍

▲

❍

▲

❍

▲

5

Thermistor

✕

✕

✕

✕

✕

✕

✕

✕

✕

Clean and remove

paper dust.

paper dust.

6

Upper heat roller gear

✕

▲

✕

▲

✕

▲

✕

▲

7

CL roller

✕

✕

▲

✕

▲

✕

▲

✕

▲

8

CL roller bearing

✕

✕

▲

✕

▲

✕

▲

✕

▲

9

Paper guides

❍

❍

❍

❍

❍

❍

❍

❍

❍

10

Gears

✩

✩

✩

✩

✩

✩

✩

✩

5

3

4

1

6

5

8

2

7

8

AR-M351U/M451U, AR-M355U/M455U MAINTENANCE AND DETAILS OF EACH SECTION 7 - 24

(2) Maintenance and parts replacement

a. Fusing unit

1) Pull out the left door.

2) Remove the stopper R.

3) Pull the fusing lever, and remove the fusing unit.

a-1. Lower separation pawl

1) Remove the fusing unit.

2) Open the fusing rear lower PG, and remove the lower separa-

tion pawl.

a-2. Upper separation pawl

1) Remove the fusing unit.

2) Remove the rear upper PG, and remove the upper separation

pawl.

No.

Unit

Parts

a

Fusing unit

1

Lower separation pawl

❍

2

Upper separation pawl

❍

3

Thermistor

✕

4

Lower heat roller

✕

5

CL roller

✕

6

CL roller bearing

✕

7

Heater lamp

8

Upper heat roller

✕

9

Upper heat roller gear

✕

10

Thermostat

a-1

a-3

a-2

a-6

a-3

a-3

a-10

a-4

a-8

a-9

a

a-6

a-5

a-7