Read Sharp AR-C270 (serv.man6) Service Manual online

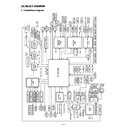

[5] EXTERNAL VIEW AND INTERNAL STRUCTURE

B. Internal parts

(1) Cross section

No.

Parts

Note

Name

Function and operation

1

No. 2 mirror

Sends the original image to No. 3 mirror.

2

No. 3 mirror

Send the original image to the CCD.

3

Y-LSU unit

Converts yellow components of image signals sent from the ICU PWB into laser

beams, and radiates the beams onto the OPC drum.

beams, and radiates the beams onto the OPC drum.

4

M-LSU unit

Converts magenta components of image signals sent from the ICU PWB into laser

beams, and radiates the beams onto the OPC drum.

beams, and radiates the beams onto the OPC drum.

5

No. 1 mirror

Sends the original image to No. 2 mirror.

6

Scanner lamp

Radiates light to the CCD for scanning the original image.

7

CCD lens

Reduces the original image (light) and project it to the CCD.

8

C-LSU unit

Converts cyan components of image signals sent from the ICU PWB into laser

beams, and radiates the beams onto the OPC drum.

beams, and radiates the beams onto the OPC drum.

9

CCD PWB

Reads the original image and converts it into electrical signals.

10

K-LSU unit

Converts black components of image signals sent from the ICU PWB into laser

beams, and radiates the beams onto the OPC drum.

beams, and radiates the beams onto the OPC drum.

11

Developing roller (Y)

Attaches toner on the OPC drum. (Y)

12

Developing roller (M)

Attaches toner on the OPC drum. (M)

13

Developing roller (C)

Attaches toner on the OPC drum. (C)

14

Developing roller (K)

Attaches toner on the OPC drum. (K)

15

Upper resist roller

Transports paper to the transfer section.

16

Lower resist roller

Transports paper to the transfer section.

17

Paper transport roller 1

Transports paper to the transfer resist roller.

18

Idle roller

Applies pressure to paper and the transport roller.

19

Idle roller

Prevents against paper skew.

20

Paper transport roller 1

Transports paper to the transfer section (transfer resist roller).

21

Paper feed tray (No. 1 paper tray)

Feeds paper to the paper transport section.

22

Separation roller (No. 1 paper tray)

Separates paper and transport it to the paper transport section.

1 2

3 4

5

6

7

8

9

11

12

13

14

15

16

12

13

14

15

16

17

18

18

19

20

21

22

23

24

25

26

27

28

29

30

22

23

24

25

26

27

28

29

30

31

33

34

34

37

39

40

41

42

43

44

45

46

47

48

49

67

51

52

53

54

55

56

57

58

59

60

35

32

36

61

62

63

64

65

66

10

38

50

68

75

70

69

72

71

73

74

76

77

5 – 4A

No.

Parts

Note

Name

Function and operation

23

Paper pickup roller (No. 1 paper tray)

Sends paper to the paper feed roller.

24

Idle roller

Applies pressure to paper and the transport roller.

25

Paper transport roller 2

Transports paper to the transport roller 1.

26

Paper feed roller (No. 2 paper roller)

Feeds paper to the paper transport section.

27

Separation roller (No. 2 paper tray)

Separates paper and prevents against double feed.

28

Paper pickup roller (No. 2 paper tray)

Sends paper to the paper feed roller.

29

Idle roller

Applies pressure to paper and the transport roller.

30

Paper transport roller 3

Transports paper to the transport roller 2.

31

Paper feed roller (No. 3 paper tray)

Feeds paper to the paper transport section.

32

Separation roller (No. 3 paper tray)

Separates paper and prevents against double feed.

33

Paper pickup roller (No. 3 paper tray)

Feeds paper to the paper feed roller.

34

Idle roller

Applies pressure to paper and the transport roller.

35

Paper transport roller 4

Transports paper to the transport roller 3.

36

Paper feed roller (No. 4 paper tray)

Feeds paper to the paper transport section.

37

Separation roller (No. 4 paper tray)

Separates paper and prevents against double feed.

38

Paper pickup roller (No. 4 paper tray)

Sends paper to the paper feed roller.

39

Transfer roller (K)

Applies a transfer voltage to the transfer belt.

40

OPC drum unit (K)

Forms black latent electrostatic images.

41

Main charger unit (K)

Charges the black OPC drum negatively.

42

OPC drum unit (C)

Forms cyan latent electrostatic images.

43

Transfer roller (C)

Applies a transfer voltage to the transfer belt.

44

Main charger unit (C)

Charges the cyan OPC drum negatively.

45

OPC drum unit (M)

Forms magenta latent electrostatic images.

46

Transfer roller (M)

Applies a transfer voltage to the transfer belt.

47

Main charger unit (M)

Charges the magenta OPC drum negatively.

48

OPC drum unit (Y)

Forms yellow latent electrostatic images.

49

Transfer roller (Y)

Applies a transfer voltage to the transfer belt.

50

Main charger unit (Y)

Charges the yellow OPC drum negatively.

51

Transfer belt

Transfers toner images on the OPC drum to paper.

52

Waste toner bottle

Collects waste toner.

53

Oil tank

Stores oil.

54

Lower heater lamp

Heats the lower heat roller.

55

Lower heat roller

Applies a pressure and heat to toner and fuses it to paper.

56

Lower separation pawl

Separates paper mechanically from the lower heat roller.

57

Fusing transport roller

Transports paper to the paper exit roller.

58

ADU gate

Switches the paper route in the duplex mode.

59

Paper exit roller

Discharges paper outside the machine.

60

Idle roller

Applies pressure to paper and the paper exit roller.

61

Idle roller

Applies pressure to paper and the transport roller.

62

Upper cleaning roller

Cleans the fusing roller.

63

Upper heat roller

Applies a pressure and heat to toner and fuses it to paper.

64

Upper heat lamp

Heats the upper heat roller.

65

Oil roller

Applies oil to the upper heat roller.

66

Oil blade

Controls oil quantity on the oil roller to be even.

67

Separation pawl

Separates paper from the transfer belt mechanically.

Japan only

68

Waste toner bottle

Collects waste toner from transfer belt.

69

Paper pickup roller

Sends paper to the paper feed roller.

Manual paper

feed section

feed section

70

Paper pickup solenoid

Presses paper onto the paper pickup roller.

71

Manual paper feed roller

Feeds paper to the paper transport section.

72

Manual paper feed clutch

Transmits the paper feed drive motor power to the manual paper feed unit.

(Controls ON/OFF of the manual paper feed unit.)

(Controls ON/OFF of the manual paper feed unit.)

73

Separation roller

Separates paper to prevent against double feed.

74

Manual transport roller

Applies a pressure to paper and the transport roller to give the transport roller

power to the paper.

power to the paper.

75

Idle roller

Applies a pressure to paper and the transport roller and gives a transport power of

the transport roller to the paper.

the transport roller to the paper.

76

Resist roller cleaner

Clean the resist roller.

AR-C160/C270

5 – 5A

f. Transfer section

No.

Parts

Model

Note

Code

Signal

name

Name

Type

Function/Operation

Active

condition

1

Transfer unit

Transfers toner from the OPC

drum to paper.

drum to paper.

2

Transfer belt

separation pawl

separation pawl

Separates paper from the

transfer belt mechanically.

transfer belt mechanically.

Japan only

3

BPSS

BPSS

Separation pawl

solenoid

solenoid

Drives the separation

solenoid.

solenoid.

Japan only

4

Transfer belt

drive roller

drive roller

Drives the transfer belt.

5

Transfer

discharge

electrode

discharge

electrode

Discharges electric charges

of the transfer belt.

of the transfer belt.

4 pcs (Y, M, C,

K)

K)

6

Transfer roller

Applies a transfer voltage to

the transfer belt.

the transfer belt.

4 pcs (Y, M, C,

K)

K)

7

Lift cam

Transmits the transfer belt lift

motor power to the transfer

unit.

motor power to the transfer

unit.

Lifted up in

color print

mode, and lifted

down in

monochrome

mode.

color print

mode, and lifted

down in

monochrome

mode.

8

PCS

PCS

Image density

sensor

sensor

Photo sensor

(Photo reflection)

(Photo reflection)

Detects toner patch density in

image density correction.

image density correction.

Analog input

9

BLUM

BLUM

Transfer belt

motor

motor

Stepping motor

Lifts the transfer belt unit.

1

2

3

4

5

6

7

8

9

10

11

12

15

16

18

19

20

21

22

13

14

16

10

8

12

15

5

6

4

3

2

7

5

5

5

6

6

6

23

24

25

26

27

14

13

28

28

5 – 6A