Read Sharp AR-C270 (serv.man15) Service Manual online

[11] MAINTENANCE AND DISASSEMBLY/ASSEMBLY

1. Necessary procedure for maintenance and servicing

(1) Items to be performed before maintenance servicing 1

Item

Simulation

Check the print counter value of each section in each operation mode.

22

1

Check the number of times of paper jams and troubles.

22

2

22

3

22

12

22

4

Prints the list of setups and adjustment values.

22

6

Check the number of use of the RADF, the sorter and the scanner.

22

8

Check the number of use of paper feed sections.

22

9

11 – 1

No

1

2

3

4

5

6

7

8

9

10

11

22 (Auto)/

20 (Manual)

22 (Auto)/

21 (Manual)

ADJ M9A

(ADJ M9)

ADJ M8

ADJ M7

ADJ M6

ADJ M5

ADJ M3

ADJ M9A

(ADJ M10)

JOB No

Work item

Simulation

When

installing

Repair (When a consumable part is replaced)/maintenance

After replacing

OPC drum (

∗

1)

After replacing

developer (

∗

2)

After replacing

transfer belt

After disposing

transfer section

waste toner

After cleaning

scanner

(reading) section

When in

periodic

maintenance

When in

repair/check

(without replacing

consumable parts)

Toner concentration reference control level setup

Developer counter clear

OPC drum counter clear

Image density sensor adjustment

Image density sensor position adjustment

Image skew adjustment

OPC drum phase adjustment

Transfer section waste toner counter clear

Half-tone correction level is set to zero.

Main scan direction image resist adjustment

Sub scan direction image resist adjustment

25

24

24

44

44

64

44

24

44

50

50

(2) Necessar

y w

ork items in maintenance ser

vice

The w

o

rk

items necessar

y f

or maintenance are sho

wn belo

w

.

P

erf

or

m the w

o

rk

according to the f

ollo

wing descr

iption when other than maintenance (when replacing a consumab

le par

t/when repa

ir

ing and chec

king (without replacement of consumab

le par

ts)/

when installing/when cleaning the scanner (reading) section/etc.)

Job No

. indicates the title n

umber of adjustment items specified in the chapter of the adjustments

. Ref

er to Use this n

umber wh

en ref

err

ing to the details

, as necessar

y.

When the de

v

eloper counter is cleared (SIM 24-5) and the OPC dr

um counter is cleared (SIM 24-7), the image density correction (

process correction) is automatically perf

or

med.

2

5

7

13

23

1

20 (Old)/31 (New)

8

27

∗

∗

∗

∗

∗

∗ ∗

∗

∗ ∗

∗

∗

∗

12

ADJ M17

Copy quality adjustment

∗

∗

∗

∗

11 – 2

(3) Items to be performed after maintenance servicing 3

Item

Simulation

Paper jam, trouble data clear

24

1

Each paper feed section use number counter clear

24

2

RADF, sorter, scanner use number counter clear

24

3

Maintenance counter clear

24

4

Setup and adjustment data output

22

6

(4) Maintenance display

When the maintenance timing is reached, the following display is shown.

MAINTENANCE REQUIRED CODE: XX

The above two-digit code indicates the kind and the count of the maintenance counter.

The meaning of the CODE indication is as shown below.

CODE (XX) 1st digit

Meaning

A

5K

Maintenance counter value set with SIM 21-1.

B

10K

C

15K

D

20K

E

40K

F

80K

CODE (XX) 2nd digit

Meaning

T

The total maintenance counter has reached the value set with SIM 21-1.

C

The color maintenance counter has reached the value set with SIM 21-1.

A

Both the total maintenance counter and the color maintenance counter have reached the values set with SIM 21-1.

After completion of maintenance, reset this display with SIM 24-4.

11 – 3

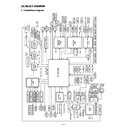

2. List

•

OIL/GRE (Lubricate, grease); CLN (Cleaning); ADJ (Adjustment); REP (Replacement, installation); CP (Change position); CHK (Check); (Clean,

replace, lubricate, grease as necessary); ABL (Disassembly, assembly)

replace, lubricate, grease as necessary); ABL (Disassembly, assembly)

S01

External fitting section

Unit

Part

JOB

CODE

Every

service

call

40K

80K

120K

160K

200K

240K

280K

320K

Remark

U No.

Unit name

P No.

Part name

P01

Original cover

ABL

CLN

∗

∗

∗

∗

∗

∗

∗

∗

∗

P02

Rear cabinet upper

ABL

P03

Rear cabinet lower

ABL

P04

Front cabinet

ABL

P05

Glass holder right

ABL

P06

Glass holder left

ABL

P07

Table glass

CLN

∗

∗

∗

∗

∗

∗

∗

∗

∗

ABL

P08

Shading glass

CLN

∗

∗

∗

∗

∗

∗

∗

∗

∗

ABL

P09

Upper cabinet right

ABL

P10

Upper cabinet left

ABL

P11

Right cabinet upper

ABL

P12

Right cabinet lower rear

ABL

P13

Right cabinet lower front

ABL

P14

Right cabinet lower front

ABL

P15

Left cabinet upper

ABL

P16

Left cabinet lower

ABL

S01/P01/CLN

S01/P02

S01/P03

S01/P04

S01/P05

S01/P06/CLN

S01/P07/CLN

S01/P09

S01/P10

S01/P11

S01/P12

S01/P15

S01/P16

S01/P13

S01/P14

S01/P08/CLN

S01/Ua01

11 – 4