Read Sharp AR-205 (serv.man9) Service Manual online

CODE: 00ZAR205//A1E

DIGITAL COPIER

AR-160

AR-161

AR-200

AR-161

AR-200

MODEL

AR-205

Parts marked with "

" are important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safty and performance of the set.

[ 1 ] GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 2 ] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[ 3 ] CONSUMABLE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[ 4 ] EXTERNAL VIEWS AND INTERNAL STRUCTURE . . . . . . . . . . . . . . . 4-1

[ 5 ] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[ 6 ] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[ 7 ] SIMULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[ 8 ] USER PROGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[ 9 ] TROUBLE CODE LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

[11] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

[12] FLASH ROM VERSION UP PROCEDURE . . . . . . . . . . . . . . . . . . . . . 12-1

[13] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

CONTENTS

AR-205

SHARP CORPORATION

AR-205 COVER 05/24/1999

AR-205

Warning!

This product is a class A product.

If it is operated in households, offices or similar surroundings, it

can produce radio interferences at other appliances, so that the

user has to take adequate countermeasures.

This product is a class A product.

If it is operated in households, offices or similar surroundings, it

can produce radio interferences at other appliances, so that the

user has to take adequate countermeasures.

CLASS 1 LASER PRODUCT

LASER KLASSE 1

LUOKAN 1 LASERLAITE

KLASS 1 LASERAPPARAT

VAROITUS!

LAITTEEN KÄYTTÄMINEN

MUULLA KUIN TÄSSÄ

KÄYTTÖOHJEESSA MAINITULLA

TAVALLA SAATTAA ALTISTAA

KÄYTTÄJÄN

TURVALLISUUSLUOKAN 1

YLITTÄVÄLLE

NÄKYMÄTTÖMÄLLE

LASERSÄTEILYLLE.

MUULLA KUIN TÄSSÄ

KÄYTTÖOHJEESSA MAINITULLA

TAVALLA SAATTAA ALTISTAA

KÄYTTÄJÄN

TURVALLISUUSLUOKAN 1

YLITTÄVÄLLE

NÄKYMÄTTÖMÄLLE

LASERSÄTEILYLLE.

VARNING

OM APPARATEN ANVÄNDS PÅ

ANNAT SÄTT ÄN I DENNA

BRUKSANVISNING

SPECIFICERATS, KAN

ANVÄNDAREN UTSÄTTAS FÖR

OSYNLIG LASERSTRÅLNING,

SOM ÖVERSKRIDER GRÄNSEN

FÖR LASERKLASS 1.

ANNAT SÄTT ÄN I DENNA

BRUKSANVISNING

SPECIFICERATS, KAN

ANVÄNDAREN UTSÄTTAS FÖR

OSYNLIG LASERSTRÅLNING,

SOM ÖVERSKRIDER GRÄNSEN

FÖR LASERKLASS 1.

CAUTION

VORSICHT

ADVARSEL

VORSICHT

ADVARSEL

ADVERSEL

VARNING

VARO!

VARNING

VARO!

INVISIBLE LASER RADIATION WHEN OPEN AND INTERLOCKS DEFEATED.

AVOID EXPOSURE TO BEAM.

AVOID EXPOSURE TO BEAM.

UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET UND

SICHERHEITSVERRIEGELUNG ÜBERERÜCKT. NICHT DEM STRAHL AUSSETZEN.

SICHERHEITSVERRIEGELUNG ÜBERERÜCKT. NICHT DEM STRAHL AUSSETZEN.

USYNLIG LASERSTRÅLING VED ÅBNING, NÅR SIKKERHEDSAFBRYDERE ER

UDE AF FUNKTION. UNDGA UDSAETTELSE FOR STRÅLING.

UDE AF FUNKTION. UNDGA UDSAETTELSE FOR STRÅLING.

USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES OG SIKKERHEDSLÅS BRYTES.

UNNGÅ EKSPONERING FOR STRÅLEN.

UNNGÅ EKSPONERING FOR STRÅLEN.

OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD OCH SPÄRRAR ÄR

URKOPPLADE. STRÅLEN ÄR FARLIG. BETRAKTA EJ STRÅLEN.

URKOPPLADE. STRÅLEN ÄR FARLIG. BETRAKTA EJ STRÅLEN.

AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA NÄKYMÄTÖNTÄ

LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

Laserstrahl

CLASS 1

LASER PRODUCT

LASER KLASSE 1

Disconnect the AC cord before servicing the unit.

AR-205 COVER 05/24/1999

[6] ADJUSTMENTS

1. Adjustment item list

Section

Adjustment item

Adjustment procedure/SIM No.

A

Process

section

section

(1)

Developing doctor gap adjustment

Developing doctor gap adjustment

(2)

MG roller main pole position adjustment

MG roller main pole position adjustment

(3)

Developing bias voltage output adjustment

(4)

Main charger voltage output adjustment

B

Mechanism

section

section

(1)

Image lead edge position adjustment

SIM 50-1

(2)

Main scanning direction (FR direction) distortion

balance adjustment

balance adjustment

No. 2/3 mirror base unit installing position adjustment

Copy lamp unit installing position adjustment

(3)

Main scanning direction (FR direction) distortion

adjustment

adjustment

Rail height adjustment

(4)

Sub scanning direction (scanning direction) distortion

adjustment

adjustment

Winding pulley position adjustment

(5)

Main scanning direction (FR direction) magnification

ratio adjustment

ratio adjustment

SIM 48-1

(6)

Sub scanning direction (scanning direction)

magnification ratio adjustment

magnification ratio adjustment

a

OC mode in copying (SIM 48-2)

b

SPF mode in copying (SIM 48-5)

c

OC mode in FAX (SIM 48-6)

d

SPF mode in FAX (SIM 48-7)

(7)

Off center adjustment

a

OC mode (SIM 50-13)

b

SPF mode (SIM 50-16)

(8)

OC (SPF) open/close detection position adjustment

OC (SPF) open/close detection position adjustment

(9)

Document size detection sensor

SIM 41-3

C

Image density

adjustment

adjustment

(1)

Copy mode

SIM 46-1

2. Copier adjustment

A. Process section

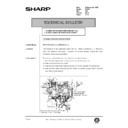

(1) Developing doctor gap adjustment

1) Loosen the developing doctor fixing screw A.

2) Insert a thickness gauge of 1.5mm to the three positions at 20mm

and 130mm from the both ends of the developing doctor as

shown.

shown.

3) Push the developing doctor in the arrow direction, and tighten the

developing doctor fixing screw. (Perform the same procedure for

the front and the rear frames.)

the front and the rear frames.)

4) Check the clearance of the developing doctor. If it is within the

specified range, then fix the doctor fixing screw with screw lock.

*

When inserting a thickness gauge, be careful not to scratch the

developing doctor and the MG roller.

developing doctor and the MG roller.

<Adjustment specification>

Developing doctor gap

Both ends (20mm from the both ends): 1.5

−

0.15

+

0.1

mm

C (Center)(150mm from the both ends): 1.55

−

0.2

+

0.15

mm

(2) MG roller main pole position adjustment

1) Remove and separate the waste toner box and put the developing

unit on a flat surface.

2) Tie a string to a needle or a pin.

3) Hold the string and bring the needle close to the MG roller

horizontally. (Do not use paper clip, which is too heavy to make a

correct adjustment.) (Put the developing unit horizontally for this

adjustment.)

correct adjustment.) (Put the developing unit horizontally for this

adjustment.)

4) Do not bring the needle into contact with the MG roller, but bring it

to a position 2 or 3mm apart from the MG roller. Mark the point on

the MG roller which is on the extension line from the needle tip.

the MG roller which is on the extension line from the needle tip.

5) Measure the distance from the marking position to the top of the

doctor plate of the developing unit to insure that it is 18mm.

If the distance is not within the specified range, loosen the fixing

screw A of the main pole adjustment plate, and move the adjust-

ment plate in the arrow direction to adjust.

If the distance is not within the specified range, loosen the fixing

screw A of the main pole adjustment plate, and move the adjust-

ment plate in the arrow direction to adjust.

AR-205

AR-205 [6] ADJUSTMENT 05/24/1999

6 – 1

(3) Developing bias voltage adjustment

Note:

•

Use a digital multi-meter with an internal resistance of

10M

10M

Ω

or more.

1) Set the digital multi-meter range to DC700V.

2) Put the test rod of the digital multi-meter on the developing bias

voltage output check pin.

3) Turn on the power.

4) Adjust the adjustment volume VR31 so that the output voltage is

within the specified range shown below.

<Adjustment specification>

Mode

Specification

Developing bias voltage

DC-400

±

8V

VR31

(4) Grid bias voltage adjustment

Note:

•

Use a digital multi-meter with an internal resistance of

10M

10M

Ω

or more.

1) Set the digital multi-meter range to DC700V.

2) Put the test rod of the digital multi-meter on the grid bias voltage

output check pin.

3) Turn on the power.

4) Adjust the adjustment volumes (VR51, VR52) so that the output

voltage is within the specified range. (The voltage is outputted in

the grid bias high output mode during warming up, and in the grid

bias low output mode after completion of warming up.)

the grid bias high output mode during warming up, and in the grid

bias low output mode after completion of warming up.)

<Adjustment specification>

Mode

Specification

Grid bias LOW

DC-400

±

20V

VR52

Grid bias HIGH

DC-525

±

10V

VR51

B. Mechanism section

(1) Image lead edge position adjustment (SIM 50-1)

a. OC image lead edge position adjustment

Note: In advance to this adjustment, the sub scanning magnification

Note: In advance to this adjustment, the sub scanning magnification

ratio adjustment must be performed.

1) Set a scale on the OC table as shown below.

2) Make a copy.

3) Check the copy output. If necessary, perform the following adjust-

ment procedures.

4) Execute SIM 50-1.

5) Set the OC lead edge position set value (Exposure display

<AUTO> ON) to “99.”

The OC image scanning start position is shifted inside the docu-

ment edge.

The OC image scanning start position is shifted inside the docu-

ment edge.

6) Set the main cassette lead edge void adjustment value (Exposure

display <PHOTO> ON) * to “1.”

The lead edge void becomes the minimum.

The lead edge void becomes the minimum.

7) Set the print start position value (Exposure display <EXP1> ON)

to “99” and make a copy.

The print start position is shifted inside the document edge.

The print start position is shifted inside the document edge.

8) Measure the image loss R of the copied image. Enter the set

value of the image scanning lead edge position (Exposure display

<AUTO> ON) again.

<AUTO> ON) again.

•

1 step of the set value corresponds to about 0.127mm shift.

•

Calculate the set value from the formula below.

99 - R/0.127 (mm) = Image loss set value <R: Image loss meas-

urement value (mm)>

urement value (mm)>

Example: 99 - 4/0.127 = 99 - 31.5 = about 67

Note: If the set value is not obtained from the above formula,

perform the fine adjustment.

5

10

5mm

4mm

*

The dimension varies depending on the model.

10

5mm

0mm

5

*

The scanning edge is set.

(A line may be printed by scanning the document edge.)

AR-205

AR-205 [6] ADJUSTMENT 05/24/1999

6 – 2