Read Sharp AR-122E (serv.man9) Service Manual online

AR-122E/152E/153E/157E SIMULATION, TROUBLE CODES 10 - 1

[10] SIMULATION, TROUBLE CODES

1. Entering the simulation mode

To enter the serviceman simulation mode, press the keys as follows:

Clear

→

Density select

→

Clear

→

Density select

To cancel the simulation mode, press the clear key.

Flow chart of entering the simulation mode

Flow chart of entering the simulation mode

1

YES

NO

NO

YES

YES

YES

1

NO

NO

YES

Is there a sub

code ?

code ?

Press the COPY

key.

key.

Press the COPY key.

The COPY QUANTITY

display blinks to indicate

"00" and the machine

display blinks to indicate

"00" and the machine

enters the ready

state for sub code input.

state for sub code input.

Enter the sub code with

the COPY QUANTITY key.

the COPY QUANTITY key.

10th digit

1st digit:

Press the COPY key.

The current set adjustment

value and the counter

value are displayed on the

COPY QUANTITY

value and the counter

value are displayed on the

COPY QUANTITY

displayed Sensor check,

etc. are displayed by the

etc. are displayed by the

alarm lamps, etc.

To change the current set

values, enter with the COPY

QUANTITY key.

values, enter with the COPY

QUANTITY key.

10th digit:

1st digit:

Count up of values:

COPY QUANTITY key

COPY QUANTITY key

Count down of values:

Zoom key + COPY

QUANTITY key

Zoom key + COPY

QUANTITY key

The entered value

is displayed on the

COPY QUANTITY

display.

is displayed on the

COPY QUANTITY

display.

Press the COPY

key.

key.

The entered value

is registered.

is registered.

Is it the

Perform the operation

according to the

simulation number.

according to the

simulation number.

performed ?

Press the clear key.

All displays on the

operation panel go off,

and the machine enters

the ready state for

entering the main code.

operation panel go off,

and the machine enters

the ready state for

entering the main code.

Press the clear key.

End

Is the

main code the

same ?

main code the

same ?

Is the

sub code

displayed ?

sub code

displayed ?

Press the clear key.

The COPY QUANTITY

display blinks to indicate

the previously set sub

enters the ready 7 state for

sub code input.

display blinks to indicate

the previously set sub

enters the ready 7 state for

sub code input.

code, and the machine

Press the clear key.

Enter the new main

code.

code.

The main code is

displayed on the

COPY QUANTITY

display.

displayed on the

COPY QUANTITY

display.

Start

Press the clear key.

Press the exposure

mode selector key.

mode selector key.

All displays on the

operation panel go off,

and the machine enters

operation panel go off,

and the machine enters

he ready state for entering

he main code.

he main code.

Count up of values:

COPY QUANTITY key

Count down of values:

Zoom key + COPY

QUANTITY key

COPY QUANTITY key

Count down of values:

Zoom key + COPY

QUANTITY key

The main code is

displayed on the

COPY QUANTITY

display.

displayed on the

COPY QUANTITY

display.

simulation for

operation

check?

Is another

simulation to be

Enter the main code with

the COPY QUANTITY key.

the COPY QUANTITY key.

10th digit:

1st digit:

Count up of values:

COPY QUANTITY key

Count down of values:

Zoom key + COPY

QUANTITY key

COPY QUANTITY key

Count down of values:

Zoom key + COPY

QUANTITY key

Press the clear key.

Press the exposure

mode selector key.

mode selector key.

Within 1sec

Within 1sec

Within 1sec

AR-122E/152E/153E/157E SIMULATION, TROUBLE CODES 10 - 2

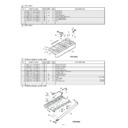

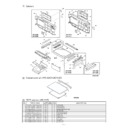

2. List of simulations

Sim

No.

Kind of

main code

Sub

code

Operation

01

Optical system

01

Mirror scan operation

06

Aging of mirror scanning

02

SPF Individual

load operation

load operation

02

SPF sensor status display

03

Motor ON

04

Paper feed solenoid ON

05

Pressure release solenoid ON

(RSPF)

(RSPF)

06

Resist clutch ON (RSPF)

07

Gate solenoid ON (RSPF)

05

Lamp ON

check

check

01

Operation panel display check

02

Fusing lamp, cooling fan operation

check

check

03

Copy lamp ON

06

Machine

individual load

operation

individual load

operation

01

Paper feed solenoid ON

02

Resist solenoid ON

07

Aging

01

Warm-up display and aging with jam

06

Intermittent aging

08

High voltage

output check

output check

01

Developing bias

02

Main charger (Grid high)

03

Grid voltage (Low)

06

Transfer charger

10

Other

None Toner motor aging

14

Trouble reset

None Cancel of troubles other than U2

16

U2 trouble

reset

reset

None Cancel of U2 trouble

20

01

Maintenance counter clear

21

01

Maintenance cycle setup

02

Mini maintenance cycle setup (Valid

only when the destination is set to

Japan AB series.)

only when the destination is set to

Japan AB series.)

22

Counter

display

display

01

Maintenance counter display

02

Maintenance preset value display

04

JAM total counter display

05

Total counter display

06

Developer counter display

08

SPF counter display

12

Drum counter display

14

P-ROM version display

17

Copy counter display

18

Printer counter display

19

Scanner mode counter display

21

Scanner counter display

22

SPF JAM counter display

24

Special

counter clear

counter clear

01

JAM total counter clear

04

SPF counter clear

06

Developer counter clear

07

Drum counter clear

08

Copy counter clear

09

Printer counter clear

13

Scanner counter clear

14

SPF JAM total counter clear

15

Scanner mode counter clear

25

Main motor

ON

ON

01

Main motor operation check (Cooling

fan motor rotation check)

fan motor rotation check)

10

Polygon motor ON

26

Various setup

01

Manual feed setup

02

(R) SPF setup

03

Second cassette setup

04

Machine duplex setup

06

Destination setup

07

Machine conditions check

20

Rear edge void setup

30

CE mark support control ON/OFF

37

Developer life-over termination

cancel

cancel

38

Cancel of stop at drum life over

39

Memory capacity check

40

Polygon motor OFF time setup

(Time required for turning OFF after

completion of printing)

(Time required for turning OFF after

completion of printing)

42

Transfer ON timing control setup

43

Side void setup

44

SPF document rear edge read setup

62

Energy-save mode copy lamp setup

63

Fan control select setup

64

Heater control setup during the

scanner mode

scanner mode

30

Sensor

operation

check

(Standard

provision)

operation

check

(Standard

provision)

01

Paper sensor status display

43

Fusing

temperature

setup

temperature

setup

01

Fusing temperature setup (Normal

copy)

copy)

04

Fusing temperature setup 2

05

Fusing temperature setup in duplex

copy

copy

09

Setup of fusing control of postcard

size paper

size paper

46

Exposure

adjustment

adjustment

01

Copy density adjustment (300dpi)

02

Copy density adjustment (600dpi)

18

Image contrast adjustment (300dpi)

19

γ

table setup or AE operation mode

setup

20

SPF exposure correction

29

Image contrast adjustment (600dpi)

31

Image sharpness adjustment

32

Copier color reproduction setup

48

Magnification

ratio correction

and black level

adjustment

ratio correction

and black level

adjustment

01

Front/rear (main scanning) direction

and scan (sub scanning) direction

magnification ratio adjustment and

black level adjustment

and scan (sub scanning) direction

magnification ratio adjustment and

black level adjustment

49

01

Flash ROM program writing mode

50

Lead edge

adjustment

adjustment

01

Lead edge image position

10

Center offset adjustment

18

Memory reverse position adjustment

in duplex copy

in duplex copy

19

Duplex copy rear edge void

adjustment

adjustment

51

Timing

adjustment

adjustment

02

Resist quantity adjustment

53

08

SPF scan position automatic

adjustment

adjustment

61

Laser system

operation

operation

03

Polygon motor check

(HSYNC output check)

(HSYNC output check)

63

Shading

01

Shading check

64

Self print

01

Self print

Sim

No.

Kind of

main code

Sub

code

Operation

AR-122E/152E/153E/157E SIMULATION, TROUBLE CODES 10 - 3

3. Contents of simulations

Input method: Clear key

→

Exposure Select key

→

Clear key

→

Exposure Select key

Main

code

code

Sub

code

Content

01

01

Mirror scan operation

(Operation/Procedure)

1. When this simulation is executed, the mirror home position is detected.

(Operation/Procedure)

1. When this simulation is executed, the mirror home position is detected.

2. When the _START key is pressed, scanning is executed at the speed corresponding to the currently set copy magnification ratio.

The copy magnification ratio can be arbitrarily set with the magnification ratio select key/zoom key.

06

Aging of mirror scanning

When the PRINT switch is pressed, the mirror base performs full scan at the speed of the set magnification ratio. After 3 sec, the mirror

case performs full scan again. These procedures are repeated until the clear key is pressed. (When the PRINT switch is pressed once,

the ready lamp keeps OFF.)

The status of the mirror home position sensor is displayed with the photoconductor cartridge lamp. (The lamp is ON when the mirror is

at the home position.)

During aging, the copy lamp keeps ON.

When the PRINT switch is pressed, the mirror base performs full scan at the speed of the set magnification ratio. After 3 sec, the mirror

case performs full scan again. These procedures are repeated until the clear key is pressed. (When the PRINT switch is pressed once,

the ready lamp keeps OFF.)

The status of the mirror home position sensor is displayed with the photoconductor cartridge lamp. (The lamp is ON when the mirror is

at the home position.)

During aging, the copy lamp keeps ON.

02

02

SPF sensor status display

ON/OFF of the sensors in the SPF can be checked with the following lamps.

ON/OFF of the sensors in the SPF can be checked with the following lamps.

03

Motor ON

(Operation/Procedure)

When the start key is pressed, the SPF motor rotates for 10 sec at the speed corresponding to the currently set magnification ratio.

(Operation/Procedure)

When the start key is pressed, the SPF motor rotates for 10 sec at the speed corresponding to the currently set magnification ratio.

04

Paper feed solenoid ON

(Operation/Procedure)

When the start key is pressed, the SPF paper feed solenoid repeats ON (500 ms) and OFF (500 ms) 20 times.

(Operation/Procedure)

When the start key is pressed, the SPF paper feed solenoid repeats ON (500 ms) and OFF (500 ms) 20 times.

05

Pressure release solenoid ON (RSPF)

(Operation/Procedure)

When the start key is pressed, the RSPF document transport solenoid (SPFS) repeats ON (500 ms) and OFF (500 ms) 20 times.

(Operation/Procedure)

When the start key is pressed, the RSPF document transport solenoid (SPFS) repeats ON (500 ms) and OFF (500 ms) 20 times.

06

Resist clutch ON (RSPF)

(Operation/Procedure)

When the start key is pressed, the RSPF resist clutch (SRRC) repeats ON (500 ms) and OFF (500 ms) 20 times.

(Operation/Procedure)

When the start key is pressed, the RSPF resist clutch (SRRC) repeats ON (500 ms) and OFF (500 ms) 20 times.

07

Gate solenoid ON (RSPF)

(Operation/Procedure)

When the start key is pressed, the RSPF gate solenoid (SGS) repeats ON (500 ms) and OFF (500 ms) 20 times.

(Operation/Procedure)

When the start key is pressed, the RSPF gate solenoid (SGS) repeats ON (500 ms) and OFF (500 ms) 20 times.

05

01

Operation panel display check

• When the PRINT switch is pressed, all LEDs (including 7-segment LEDs) on the operation panel are lighted. (LED check mode)

• When the PRINT switch is pressed, all LEDs (including 7-segment LEDs) on the operation panel are lighted. (LED check mode)

• When 1Up key is pressed, the LEDs on the operation panel are lighted individually from the top left to the bottom right in sequence.

After completion of all individual lighting, all LEDs are lighted simultaneously. (The 7-segment LED lights the three-digit sections at

the same time.)

Individual lighting frequency

ON: 300ms,

OFF: 20ms

• When the CLEAR key is pressed, this simulation is terminated.

• When the PRINT switch is pressed in the LED check mode, the machine enters the Key input check mode.

“Key input check mode”

When the machine enters the Key input check mode, the value display section indicates “– – –.” Every time any key on the operat ion

panel is pressed, the entered value is added and displayed on the value display section. However, the keys that were pressed once are

not counted again.

• When the PRINT switch is pressed, the entered value is added and displayed for 3 sec and all the LEDs are lighted. (LED lighting

When the machine enters the Key input check mode, the value display section indicates “– – –.” Every time any key on the operat ion

panel is pressed, the entered value is added and displayed on the value display section. However, the keys that were pressed once are

not counted again.

• When the PRINT switch is pressed, the entered value is added and displayed for 3 sec and all the LEDs are lighted. (LED lighting

check mode)

(Note for Key input check mode)

• Press the PRINT switch at the end. (If it is pressed in the middle of the process, the entered value up to that moment is displayed for

• Press the PRINT switch at the end. (If it is pressed in the middle of the process, the entered value up to that moment is displayed for

3 sec and the machine enters the LED lighting check mode. (ALL the LEDs are lighted.))

• Multiple key inputs are ignored.

02

Fusing lamp, cooling fan operation check

When the PRINT switch is pressed, the fusing lamp repeats operations of 500ms-ON and 500ms-OFF 5 times. During that time, the

cooling fan motor rotates.

When the PRINT switch is pressed, the fusing lamp repeats operations of 500ms-ON and 500ms-OFF 5 times. During that time, the

cooling fan motor rotates.

Sensor name

Display lamp

Mirror home position sensor

OPC drum cartridge replacement lamp

Display

Sensor

Developer cartridge replacement lamp

Document set detection (SPID)

Jam lamp

SPF document transport detection (SPPD)

Photoconductor cartridge replacement lamp

SPF cover open/close detection (SDOD)

SPF jam lamp

SPF open/close detection (SDSW)

FAX document size detection

Paper size detection

FAX document size detection

Paper size detection

AR-122E/152E/153E/157E SIMULATION, TROUBLE CODES 10 - 4

05

03

Copy lamp ON

(Operation/Procedure)

When the START key is pressed, the copy lamp is lighted for 5 sec.

(Operation/Procedure)

When the START key is pressed, the copy lamp is lighted for 5 sec.

06

01

Paper feed solenoid ON

(Operation/Procedure)

When the START key is pressed, the paper feed solenoid selected by the tray select key repeats ON (500ms) and OFF (500ms) 20

times.

(Operation/Procedure)

When the START key is pressed, the paper feed solenoid selected by the tray select key repeats ON (500ms) and OFF (500ms) 20

times.

02

Resist solenoid ON

(Operation/Procedure)

When the START key is pressed, the resist solenoid (RRS) repeats ON (500ms) and OFF (500ms) 20 times.

(Operation/Procedure)

When the START key is pressed, the resist solenoid (RRS) repeats ON (500ms) and OFF (500ms) 20 times.

07

01

Warm-up display and aging with jam

(Operation/Procedure)

1. When the simulation is executed, warming up is started.

2. Warm-up time is counted and displayed every second on the copy quantity display.

3. After completion of warm-up, the time count is stopped and the ready lamp is lighted.

4. Press the clear key to clear the warm-up time display, set the copy quantity, and press the START key, and the machine will copy

(Operation/Procedure)

1. When the simulation is executed, warming up is started.

2. Warm-up time is counted and displayed every second on the copy quantity display.

3. After completion of warm-up, the time count is stopped and the ready lamp is lighted.

4. Press the clear key to clear the warm-up time display, set the copy quantity, and press the START key, and the machine will copy

the set quantity repeatedly.

This simulation is canceled by turning off the power or executing any simulation which performs hardware reset.

06

Intermittent aging

(Operation/Procedure)

1. When the simulation is executed, warming up is started.

2. After completion of warm-up, the ready lamp is lighted.

3. Set the copy quantity and press the START key, and the machine will copy the set quantity repeatedly.

4. After 3 sec of the interval time from completion of copying the set quantity, the machine will resume copying.

5. The above operation 4 is repeated.

This simulation is canceled by turning off the power or executing any simulation which performs hardware reset.

(Operation/Procedure)

1. When the simulation is executed, warming up is started.

2. After completion of warm-up, the ready lamp is lighted.

3. Set the copy quantity and press the START key, and the machine will copy the set quantity repeatedly.

4. After 3 sec of the interval time from completion of copying the set quantity, the machine will resume copying.

5. The above operation 4 is repeated.

This simulation is canceled by turning off the power or executing any simulation which performs hardware reset.

08

01

Developing bias

(Operation/Procedure)

When the START key is pressed, the developing bias is outputted for 30 sec.

(Operation/Procedure)

When the START key is pressed, the developing bias is outputted for 30 sec.

02

Main charger (Grid high)

(Operation/Procedure)

When the START key is pressed, the main charger output is supplied for 30 sec in the grid voltage HIGH mode.

(Operation/Procedure)

When the START key is pressed, the main charger output is supplied for 30 sec in the grid voltage HIGH mode.

03

Grid voltage (Low)

(Operation/Procedure)

When the START key is pressed, the main charger output is supplied for 30 sec in the grid voltage LOW mode.

(Operation/Procedure)

When the START key is pressed, the main charger output is supplied for 30 sec in the grid voltage LOW mode.

06

Transfer charger

(Operation/Procedure)

When the START key is pressed, the transfer charger output is supplied for 30 sec.

(Operation/Procedure)

When the START key is pressed, the transfer charger output is supplied for 30 sec.

10

None Toner motor aging

(Operation/Procedure)

When the START key is pressed, the toner motor output is supplied for 30 sec.

When the START key is pressed, the toner motor output is supplied for 30 sec.

14

None Cancel of troubles other than U2

(Operation/Procedure)

After canceling the trouble, the simulation is also automatically canceled.

After canceling the trouble, the simulation is also automatically canceled.

16

None Cancel of U2 trouble

(Operation/Procedure)

1. When the START key is pressed, the EEPROM total counter check sum is rewritten and the trouble is canceled.

2. After canceling the trouble, the simulation is also automatically canceled.

1. When the START key is pressed, the EEPROM total counter check sum is rewritten and the trouble is canceled.

2. After canceling the trouble, the simulation is also automatically canceled.

20

01

Maintenance counter clear

When the PRINT switch is pressed, the maintenance count is cleared and the value “000000” is displayed.

When the PRINT switch is pressed, the maintenance count is cleared and the value “000000” is displayed.

21

01

Maintenance cycle setup

The currently set code (default) of the maintenance cycle is displayed, and the newly set data are saved.

The currently set code (default) of the maintenance cycle is displayed, and the newly set data are saved.

Main

code

code

Sub

code

Content

Code

Setup

0

3,000 sheets

1

6,000 sheets

2

9,000 sheets

3

13,000 sheets

4

25,000 sheets

*Default

5

Free (999,999 sheets)