Read Sharp AL-1566 (serv.man12) Service Manual online

AL-1556/1566 ADJUSTMENTS 9 - 1

[9] ADJUSTMENTS

1. Optical section

A. Copy magnification ratio adjustment

The copy magnification ratio must be adjusted in the main scanning

direction and in the sub scanning direction. To adjust, use TC 48-01.

direction and in the sub scanning direction. To adjust, use TC 48-01.

(1) Outline

The main scanning (front/rear) direction magnification ratio adjustment

is made manually.

is made manually.

The adjustment is made by manual key operations. (The zoom data

register set value is changed for adjustment.)

register set value is changed for adjustment.)

The magnification ratio in the sub scanning direction is adjusted by

changing the carriage (scanner) scanning speed.

changing the carriage (scanner) scanning speed.

(2) Main scanning/sub scanning direction magnification

ratio adjustment

a. Cases when the adjustment is required

1) When the main PWB is replaced.

2) When the EEPROM in the main PWB is replaced.

3) When "U2" trouble occurs.

4) When repairing or replacing the optical section.

b. Necessary tools

• Scale

c. Main scanning direction adjustment procedure

for precise adjustment.)

2) Set the copy magnification ratio to 100%.

3) Make a copy on A4 or 81/2" x 11" paper.

4) Measure the length of the copied scale image.

5) Calculate the main scanning direction magnification ratio.

Main scanning direction magnification ratio

6) Check that the copy magnification ratio is within the specified

range. If it is not within the specified range, perform the following

procedures.

procedures.

7) Execute TC 48-01 to select the main scanning direction copy

magnification ratio adjustment mode.

To select the adjustment mode, use the [

To select the adjustment mode, use the [

←

/

→

] key.

8) Enter the new set value of main scanning direction copy

magnification ratio with the copy quantity set key, and press the

[START] key.

[START] key.

9) Change the set value and repeat the adjustment until the ratio is

within the specified range.

When the set value is changed by 1, the magnification ratio is

changed by 0.1%.

When the set value is changed by 1, the magnification ratio is

changed by 0.1%.

d. Sub scanning direction adjustment procedure

scale for precise adjustment.)

=

Copy image dimensions

X 100 (%)

Original dimension

Mode

Display

item

Default

value

LED

Main scan direction

magnification ratio

magnification ratio

F-R

50

PRINT mode lamp

OC mode sub scan

direction magnification ratio

direction magnification ratio

SCAN

50

SCAN mode lamp

100

110

120

130

150

140

mm

1/2mm

JAPAN

HARDENED

STAINLESS

Shizuoka

100

110

120

130

150

140

mm

1/2mm

JAPAN

HARDENED

STAINLESS

Shizuoka

110

10

20

10

20

(When a 100mm scale is used as the original.)

Paper feed

direction

Reference

Comparison point

Original (Scale)

Copy

AL-1556/1566 ADJUSTMENTS 9 - 2

2) Set the copy magnification ratio to 100%.

3) Make a copy on A4 or 81/2" x 11" paper.

4) Measure the length of the copied scale image.

5) Calculate the sub scanning direction copy magnification ratio

using the formula below.

6) Check that the actual copy magnification ratio is within the

specified range. (100 ± 1.0%).

If it is not within the specified range, perform the following

procedures.

If it is not within the specified range, perform the following

procedures.

7) Execute TC 48-01 to select the sub scanning direction copy

magnification ratio adjustment mode.

To select the adjustment mode, use the [

To select the adjustment mode, use the [

←

/

→

] key. (SCAN mode

lamp ON)

8) Enter the new set value of sub scanning direction copy

magnification ratio with the copy quantity set key, and press the

[START] key.

[START] key.

Repeat procedures 1) - 8) until the sub scanning direction actual copy

magnification ratio in 100% copying is within the specified range.

magnification ratio in 100% copying is within the specified range.

When the set value is changed by 1, the magnification ration is

changed by 0.1%.

changed by 0.1%.

B. Image position adjustment

The employed test commands and the contents are as follows:

The modes can be selected by pressing [

←

/

→

] key.

(*): Support for the installation models. For non-installation models,

skip.

* In the 2nd print center offset adjustment, print is made forcibly as

1to2/Long Edge from OC regardless of duplex setting.

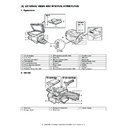

(1) Lead edge adjustment

1) Set a scale to the center of the paper lead edge guide as shown

below, and cover it with B4 or 8 1/2" x 14" paper.

2) Execute TC 50 - 01

3) Set the print start position (A: COPY mode lamp ON), the lead

edge void amount (B: PRINT mode lamp ON), the scan start posi-

tion (C: SCAN mode lamp) to 1, and make a copy of the scale at

100%.

tion (C: SCAN mode lamp) to 1, and make a copy of the scale at

100%.

4) Measure the image loss (Rmm) of the scale.

Set C = 10 x R (mm). (Example: Set to 40.)

When the value of C is increased by 10, the image loss is

decreased by 1mm. (Default: 50)

decreased by 1mm. (Default: 50)

5) Measure the distance (Hmm) from the paper lead edge to the

image print start position.

Set A = 10 x H (mm). (Example: Set to 50.)

When the value of A is increased by 10, the image lead edge is

moved to the paper lead edge by 1mm. (Default: 50).

moved to the paper lead edge by 1mm. (Default: 50).

6) Set the lead edge void amount to B = 50 (2.5mm). (Default: 50)

When the value of B is increased by 10, the void is extended by

about 0.1mm. (For 25 or less, however, the void amount is

regarded as 0.)

about 0.1mm. (For 25 or less, however, the void amount is

regarded as 0.)

* The SFP adjustment is made by adjusting the SPF image scan start

position after OC adjustment.

=

Copy image dimensions

X 100 (%)

Original dimension

Mode

Display

item

Default

LED

TC

Print start position

(Main cassette paper

feed)

(Main cassette paper

feed)

TRAY1

50

COPY mode lamp

Main cassette

lamp

Main cassette

lamp

50-01

(*) Print start position

(2nd cassette paper

feed)

(2nd cassette paper

feed)

TRAY2

50

COPY mode lamp

2nd cassette lamp

2nd cassette lamp

Print start position

(Manual paper feed)

(Manual paper feed)

MFT

50

COPY mode lamp

Manual feed lamp

Manual feed lamp

Image lead edge void

amount

amount

DEN-A

50

PRINT mode lamp

Image scan start

position

position

RRC-A

50

SCAN mode lamp

Image rear edge void

amount

amount

DEN-B

50

COPY mode lamp

PRINT mode lamp

SCAN mode lamp

PRINT mode lamp

SCAN mode lamp

100

110

120

130

150

140

mm

1/2mm

JAPAN

HARDDENCD

STAINLESS

Shizuoka

100

110

120

130

150

140

mm

1/2mm

JAPAN

HARDDENCD

STAINLESS

Shizuoka

110

10

20

10

20

Original (Scale)

Paper feed

direction

Reference

Comparison point

Copy

Mode

Display

item

Default

LED

TC

Print center offset

(Main cassette paper

feed)

(Main cassette paper

feed)

TRAY1

50

COPY mode lamp

Main cassette lamp

Main cassette lamp

50-10

(*) Print center offset

(2nd cassette paper

feed)

(2nd cassette paper

feed)

TRAY2

50

COPY mode lamp

2nd cassette lamp

2nd cassette lamp

Print center offset

(Manual paper feed)

(Manual paper feed)

MFT

50

COPY mode lamp

Manual feed lamp

Manual feed lamp

2nd print center

offset (Main cassette

paper feed)

offset (Main cassette

paper feed)

SIDE2

50

PRINT mode lamp

Main cassette lamp

Main cassette lamp

AL-1556/1566 ADJUSTMENTS 9 - 3

(Example)

(2) Image rear edge void amount adjustment

1) Set a scale to the rear edge section of A4 or 11" x 8 1/2" paper size

as shown in the figure below, and cover it with B4 or 8 1/2" x 14"

paper.

paper.

2) Execute TC 50 - 01 to select the image rear edge void amount

adjustment mode.

The set adjustment value is displayed on the copy quantity display.

The set adjustment value is displayed on the copy quantity display.

3) Make a copy and measure the void amount of image rear edge.

4) If the measurement value is out of the specified range, change the

set value and repeat the adjustment procedure.

The default value is 50.

The default value is 50.

(3) Center offset adjustment

1) Set the self-made test chart for the center position adjustment so

that its center line is aligned with the center mark of the document

guide.

guide.

• Test chart for the center position adjustment.

Draw a line at the center of A4 or 8 1/2" x 11" paper in the paper

transport direction.

transport direction.

2) Execute TC 50-10 to select the print center offset (cassette paper

feed) adjustment mode.

The set adjustment value is displayed on the copy quantity display.

The set adjustment value is displayed on the copy quantity display.

3) Make a copy and check that the copied center line is properly

positioned.

The standard value is 0 ±2mm from the paper center.

The standard value is 0 ±2mm from the paper center.

4) If the measured value is out of the specified range, change the set

value and repeat the adjustment procedure.

When the set value is increased by 1, the copy image is shifted by

0.1mm toward the rear frame.

When the set value is increased by 1, the copy image is shifted by

0.1mm toward the rear frame.

• For the manual paper feed, change the manual paper feed

adjustment mode and perform the similar procedures.

• Since the document center offset is automatically adjusted by the

CCD which scan the reference lines (F/R) on the back of document

guide, there is no need to adjust manually.

guide, there is no need to adjust manually.

2. Copy density adjustment

A. Copy density adjustment timing

The copy density adjustment must be performed in the following cases:

• When maintenance is performed.

• When the developing bias/grid bias voltage is adjusted.

• When the optical section is cleaned.

• When a part in the optical section is replaced.

• When the optical section is disassembled.

• When the OPC drum is replaced.

• When the main control PWB is replaced.

• When the EEPROM on the main control PWB is replaced.

• When the memory trouble (U2) occurs.

B. Note for copy density adjustment

1) Arrangement before execution of the copy density adjustment

• Clean the optical section.

• Clean or replace the charger wire.

• Check that the voltage at the high voltage section and the

developing bias voltage are in the specified range.

5mm

10mm

Distance from the paper lead edge

to the image lead edge, H = 5mm

to the image lead edge, H = 5mm

Image loss, R = 4mm

B4 or 8 1/2

″

×

14

″

paper

A4 size rear edge

Scale image

Paper rear edge

Void amount (Standard value: 2 - 3mm)

Document guide

(Copy A)

(Copy B)

2.0mm or less

2.0mm or less

Copy image

Copy paper

folding line

folding line

Copy image

Copy paper

folding line

folding line

Shift

Shift

(Paper feed direction)

AL-1556/1566 ADJUSTMENTS 9 - 4

C. Necessary tool for copy density adjustment

• One of the following test charts:

UKOG-0162FCZZ, UKOG-0089CSZZ, KODAK GRAY SCALE

• B4 (14" x 8 1/2") white paper

• The user program AE setting should be "3."

Test chart comparison table

D. Features of copy density adjustment

For the copy density adjustment, the image data shift function provided

in the image process LSI is used.

in the image process LSI is used.

List of the adjustment modes

E. Copy density adjustment procedure

The copy density can be adjusted in 300dpi or in 600dpi.

For selection of modes, use the copy mode select key.

(1) Test chart (UKOG-0162FCZZ) setting

1) Place the test chart so that its edge is aligned with the A4 (Letter)

reference line on the document table. Then place a A4 (14" x

8 1/2") white paper on the test chart and close the document cover.

8 1/2") white paper on the test chart and close the document cover.

(2) Perform the adjustment in each mode.

1) Execute TC 46-01 (300dpi). To adjust in 600dpi, execute TC 46-

02.

2) Select the mode to be adjusted with the exposure mode select key.

Set the exposure level to 3 (center) for all adjustment. (Except for

the auto mode.)

the auto mode.)

3) Make a copy.

Check the adjustment level (shown in the above table) of the

exposure test chart (Sharp Gray Scale).

exposure test chart (Sharp Gray Scale).

(When too bright): Decrease the value displayed on the copy quantity

display.

(When too dark):

Increase the value displayed on the copy quantity

display.

display.

* The value can be set in the range of 1 - 99.

UKOG-

0162FCZZ

DENSITY

No.

0162FCZZ

DENSITY

No.

1

2

3

4

5

6

7

8

9

10

W

UKOG-

0089CSZZ

DENSITY

No.

0089CSZZ

DENSITY

No.

0.1

0.2

0.3

0.5 1.9

0

KODAK

GRAY

SCALE

GRAY

SCALE

1

2

3

4

19

A

Auto Mode

Brightness 1 step only

Manual Mode

Brightness 5 steps. Adjustment of only the center

brightness is made.

brightness is made.

Photo Mode

Brightness 5 steps. Adjustment of only the center

brightness is made.

brightness is made.

Manual T/S

mode

mode

Brightness 5 steps. Adjustment of only the center

brightness is made.

brightness is made.

T/S Auto mode

Brightness 1 step only

Main code

Sub code

Resolution for copy density adjustment

46

01

300dpi

02

600dpi

1

10

W

2

3

4

5

6

7

8

9

White paper

Test chart

Test chart

Adjustment

mode

Display

item

LED

Sharp gray chart

adjustment level

Auto mode

AE

COPY mode lamp

"3" is slightly

copied.

copied.

Text mode

TEXT

PRINT mode lamp

"3" is slightly

copied.

copied.

Photo mode

PHOTO SCAN mode lamp

"3" is slightly

copied.

copied.

Text T/S mode

TSTXT

PRINT mode lamp

SCAN mode lamp

SCAN mode lamp

"3" is slightly

copied.

copied.

Auto T/S mode

TSAE

COPY mode lamp

SCAN mode lamp

SCAN mode lamp

"3" is slightly

copied.

copied.

Sharp Gray Scale adjustment level

Non toner

save mode

save mode

Toner save

mode

mode

(2) Mode select key

TEXT

| | | | |

| | | | |

(1) Exposure mode, level display

1

10

W

2

3

4

5

6

7

8

9

Slightly copied.

Not copied.

1

10

W

2

3

4

5

6

7

8

9

Slightly copied.

Not copied.