Read Sharp R-90GCK (serv.man5) Service Manual online

4

R-90GCK

OPERATION

DESCRIPTION OF OPERATING SEQUENCE

The following is a description of component functions

during oven operation.

during oven operation.

OFF CONDITION

Closing the door activates the door sensing switch and

secondary interlock switch and 3rd. latch switch. (In this

condition, the monitor switch contacts are opened.)

secondary interlock switch and 3rd. latch switch. (In this

condition, the monitor switch contacts are opened.)

IMPORTANT:

When the oven door is closed, the contacts COM-NC

of the monitor switch must be open. When the

microwave oven is plugged in a wall outlet (230 - 240V

/ 50Hz), the line voltage is supplied to the noise filter.

When the oven door is closed, the contacts COM-NC

of the monitor switch must be open. When the

microwave oven is plugged in a wall outlet (230 - 240V

/ 50Hz), the line voltage is supplied to the noise filter.

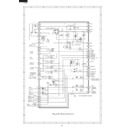

Figure O-1 on page 32

1. The display will show "PRESS STOP".

To set any program or set the clock, you must first touch

the STOP/CLEAR pad. The display will clear, and

" . 0 " will appear.

the STOP/CLEAR pad. The display will clear, and

" . 0 " will appear.

NOTE: When the door is opened, the oven lamp comes

on.

2. A signal is input to the control unit, energizing the coil

of shut-off relay (RY-4). RY4 contacts close, completing

a circuit to the damper motor. The damper motor now

operates moving the damper to the open position,

thereby closing the contacts of the damper switch

inputs a signal to the control unit. The coil of relay RY-

4 is de-energized, opening its contacts, thereby turning

off the damper motor.

a circuit to the damper motor. The damper motor now

operates moving the damper to the open position,

thereby closing the contacts of the damper switch

inputs a signal to the control unit. The coil of relay RY-

4 is de-energized, opening its contacts, thereby turning

off the damper motor.

MICROWAVE COOKING CONDITION

HIGH COOKING

Program desired cooking time by touching the TIME keys.

When the START pad is touched, the following operations

occur:

Program desired cooking time by touching the TIME keys.

When the START pad is touched, the following operations

occur:

1. The contacts of relays are closed and components

connected to the relays are turned on as follows.

(For details, refer to Figure O-2)

(For details, refer to Figure O-2)

RELAY

CONNECTED COMPONENTS

RY-1

Oven lamp/Turntable motor

RY-2

High voltage transformer

RY-3

Convection motor

RY-4

Damper motor

RY-5

Fan motor

RY-6

Convection motor

2. The line voltage is supplied to the primary winding of

the high voltage transformer. The voltage is converted

to about 3.3 volts A.C. output on the filament winding

and high voltage of approximately 2000 volts A.C. on

the secondary winding.

to about 3.3 volts A.C. output on the filament winding

and high voltage of approximately 2000 volts A.C. on

the secondary winding.

3. The filament winding voltage (3.3 volts) heats the

magnetron filament and the high voltage (2000 volts) is

sent to the voltage doubling circuit, where it is doubled

to negative voltage of approximately 4000 volts D.C..

sent to the voltage doubling circuit, where it is doubled

to negative voltage of approximately 4000 volts D.C..

4. The 2450 MHz microwave energy produced in the

magnetron generates a wavelength of 12.24 cm. This

energy is channelled through the waveguide (transport

channel) into the oven cavity, where the food is placed

to be cooked.

energy is channelled through the waveguide (transport

channel) into the oven cavity, where the food is placed

to be cooked.

5. When the cooking time is up, a signal tone is heard and

the relays RY1 + RY2 + RY5 go back to their home

position. The circuits to the oven lamp, high voltage

transformer, fan motor and turntable motor are cut off.

position. The circuits to the oven lamp, high voltage

transformer, fan motor and turntable motor are cut off.

6. When the oven door is opened during a cooking cycle,

the switches come to the following condition.

Switch

Contact

Condition

During

During

Oven Door

Cooking

Open(No cooking)

Secondary interlock

switch

switch

COM-NO

Closed

Opened

Door sensing switch

COM-NO

Closed

Opened

3rd. latch switch

COM-NO

Closed

Opened

Monitor Switch

COM-NC

Opened

Closed

The circuit to the high voltage transformer is cut off

when the contacts of relay RY2, and the contacts

(COM-NO) of the secondary interlock switch are made

open. The circuit to the fan motor is cut off when the

relay RY5 is made open. The circuit to the turntable

motor is cut off when the contacts (COM-NO) of the

secondary interlock switch are made open. The oven

lamp remains on even if the oven door is opened after

the cooking cycle has been interrupted, because the

relay RY1 stays closed. Shown in the display is

remaining time.

when the contacts of relay RY2, and the contacts

(COM-NO) of the secondary interlock switch are made

open. The circuit to the fan motor is cut off when the

relay RY5 is made open. The circuit to the turntable

motor is cut off when the contacts (COM-NO) of the

secondary interlock switch are made open. The oven

lamp remains on even if the oven door is opened after

the cooking cycle has been interrupted, because the

relay RY1 stays closed. Shown in the display is

remaining time.

7. MONITOR SWITCH CIRCUIT

The monitor switch is mechanically controlled by the

oven door, and monitors the operation of the secondary

interlock switch and the relay RY2.

oven door, and monitors the operation of the secondary

interlock switch and the relay RY2.

7-1. When the oven door is opened during or after the

cycle of a cooking program, the secondary interlock

switch and the door sensing switch must open their

contacts (COM-NO) first. After that the contacts

(COM-NC) of the monitor switch can be closed and

the contacts (COM-NO) of 3rd. latch switch are made

open.

switch and the door sensing switch must open their

contacts (COM-NO) first. After that the contacts

(COM-NC) of the monitor switch can be closed and

the contacts (COM-NO) of 3rd. latch switch are made

open.

7-2. When the oven door is closed, the contacts (COM-

NC) of the monitor switch must be opened and the

contacts (COM-NO) of 3rd. latch switch must be

closed. After that the contacts (COM-NO) of the

secondary interlock switch and the door sensing

switch are made closed.

contacts (COM-NO) of 3rd. latch switch must be

closed. After that the contacts (COM-NO) of the

secondary interlock switch and the door sensing

switch are made closed.

7-3. When the oven door is opened and the contacts

(COM-NO) of the secondary interlock switch remain

closed, the fuse F10A will blow. Because the relay

RY2 and monitor switch are closed and a short circuit

is caused.

closed, the fuse F10A will blow. Because the relay

RY2 and monitor switch are closed and a short circuit

is caused.

MEDIUM HIGH, MEDIUM, MEDIUM LOW, LOW

COOKING

COOKING

When the microwave oven is preset for variable cooking

power, the line voltage is supplied to the high voltage

transformer intermittently within a 32-second time base

through the relay contact which is coupled with the cur-

rent-limiting relay RY2. The following levels of microwave

power are given.

power, the line voltage is supplied to the high voltage

transformer intermittently within a 32-second time base

through the relay contact which is coupled with the cur-

rent-limiting relay RY2. The following levels of microwave

power are given.

5

R-90GCK

NOTE: The ON/OFF time ratio does not correspond

with the percentage of microwave power,

because approx. 3 seconds are needed for

heating of the magnetron filament.

because approx. 3 seconds are needed for

heating of the magnetron filament.

CONVECTION COOKING CONDITION

PREHEATING CONDITION

Program desired convection temperature by touching the

CONV.(˚C) key. When the START key is touched, the

following operations occur: (Figure O-3)

1. The coil of shut-off relays (RY1, RY3 and RY5) are

Program desired convection temperature by touching the

CONV.(˚C) key. When the START key is touched, the

following operations occur: (Figure O-3)

1. The coil of shut-off relays (RY1, RY3 and RY5) are

energized, the oven lamp, cooling fan motor, turntable

motor and convection motor are turned on. The contacts

(COM-NO) of relay RY6 are opened.

motor and convection motor are turned on. The contacts

(COM-NO) of relay RY6 are opened.

2. The coil of relay (RY4) is energized by the control unit.

The damper is moved to the closed position, closing

the damper switch contacts. The closing of the damper

switch contacts sends a signal to the LSI on the control

unit de-energizing the relay (RY4) and opening the

circuit to the damper motor.

the damper switch contacts. The closing of the damper

switch contacts sends a signal to the LSI on the control

unit de-energizing the relay (RY4) and opening the

circuit to the damper motor.

3. The solid-state relays are energized by the control unit

and the main supply voltage is applied to the top and

side heating elements.

side heating elements.

4. When the oven temperature reaches the selected

preheat temperature, the following operations occur:

4-1. The solid-state relays are de-energized by the

4-1. The solid-state relays are de-energized by the

control unit temperature circuit and thermistor,

opening the circuit to the heating elements.

opening the circuit to the heating elements.

4-2. The oven will continue to function for 30 minutes,

turning the heating elements on and off, as needed

to maintain the selected preheat temperature. The

oven will shutdown completely after 30 minutes

to maintain the selected preheat temperature. The

oven will shutdown completely after 30 minutes

CONVECTION COOKING CONDITION

Enter the cooking time by touching TIME keys and select

the temperature by touching CONV.(˚C) key. When the

START pad is touched, the following operations occur:

the temperature by touching CONV.(˚C) key. When the

START pad is touched, the following operations occur:

Figure O-3 on page 33

1. The numbers on the digital read-out start to count down

to zero.

2. The oven lamp, turntable motor, cooling fan motor and

convection motor are energized. The contacts (COM-

NO) of relay RY6 are opened.

NO) of relay RY6 are opened.

3. The damper is moved to the closed position.

4. The solid-state relays are energized (if the cavity

4. The solid-state relays are energized (if the cavity

temperature is lower than the selected temperature)

and the main supply voltage is applied to the heating

elements to return to the selected cooking temperature.

and the main supply voltage is applied to the heating

elements to return to the selected cooking temperature.

5. Upon completion of the cooking time, the audible signal

will sound, and oven lamp, turntable motor, cooling fan

motor and convection motor are de-energized. At the

end of the convection cycle, if the cavity air temperature

is above 111˚C, the circuit to RY5 will be maintained (by

the thermistor circuit) to continue operation of the cooling

motor and convection motor are de-energized. At the

end of the convection cycle, if the cavity air temperature

is above 111˚C, the circuit to RY5 will be maintained (by

the thermistor circuit) to continue operation of the cooling

fan motor until the temperature drops below 90˚C, at

which time the relay will be de-energized, turning off the

fan motor. Relay RY3 will however, open as soon as the

convection cycle has ended, turning off the convection

fan motor.

which time the relay will be de-energized, turning off the

fan motor. Relay RY3 will however, open as soon as the

convection cycle has ended, turning off the convection

fan motor.

6. At the end of the convection cook cycle, if the cavity air

temperature is below 120˚C, shut-off relay (RY4) is

energized turning on the damper motor. The damper is

returned to the open position, closing the damper

switch contacts which send a signal to the control unit,

de-energizing shut-off relay (RY4).

energized turning on the damper motor. The damper is

returned to the open position, closing the damper

switch contacts which send a signal to the control unit,

de-energizing shut-off relay (RY4).

GRILL COOKING

Enter cooking tim nd then touch the GRILL key. When the

start pad is touched, following operations occur;

start pad is touched, following operations occur;

Figure O-4 on page 33

1. The contacts of the relays RY1, RY3 and RY5 are

closed, and the oven lamp, turntable motor, convection

motor and fan motors are energized. The contacts

(COM-NO) of relay RY6 are closed.

motor and fan motors are energized. The contacts

(COM-NO) of relay RY6 are closed.

NOTE :The rotate direction of the convection motor is

reverse to one of the convection cooking by

the relay RY6.

the relay RY6.

2. The damper is moved to the closed position.

3. The solid-state relays are energized and the main

3. The solid-state relays are energized and the main

supply voltage is applied to the top and side heating

elements.

elements.

NOTE :After cooking, the operation of the fan motors,

damper motor is the same as one of the

convection cooking.

convection cooking.

DUAL1 COOKING

Enter cooking time and then touch DUAL1 key. When the

start pad is touched, following operations occur;

start pad is touched, following operations occur;

Figure O-5 on page 34

1. The contacts of the relays RY1, RY3 and RY5 are

closed, and the oven lamp, turntable motor, convection

motor and fan motors are energized. The contacts

(COM-NO) of relay RY6 are closed.

motor and fan motors are energized. The contacts

(COM-NO) of relay RY6 are closed.

NOTE :The rotate direction of the convection motor is

revers to one of the convection cooking.

2. The damper is moved to the closed position.

3. The solid-state relays are energized and the main

3. The solid-state relays are energized and the main

supply voltage is applied to the top and side heating

elements.

elements.

4. The relay RY2 is energized and the microwave energy

is generated by magnetron.

NOTE: After cooking, the operation of the fan motors,

damper motor is the same as one of the

convection cooking.

convection cooking.

DUAL2 COOKING

Enter cooking time and then touch DUAL2 key. When the

start pad is touched, following operations occur;

start pad is touched, following operations occur;

Figure O-6 on page 34

1. The contacts of the relays RY1, RY3 and RY5 are

closed, and the oven lamp, turntable motor, convection

motor and fan motors are energized. The contacts

(COM-NO) of relay RY6 are opened.

motor and fan motors are energized. The contacts

(COM-NO) of relay RY6 are opened.

2. The damper is moved to the closed position.

3. The solid-state relays and relay RY2 are energized,

3. The solid-state relays and relay RY2 are energized,

and the main supply voltage is applied to the top and

side heating elements and the high voltage transformer

alternately.

side heating elements and the high voltage transformer

alternately.

NOTE: After cooking, the operation of the fan motors,

damper motor is the same as one of the

convection cooking.

convection cooking.

100% (HIGH)

32 sec. ON

70% (MEDIUM

HIGH)

Approx. 70%

100%

24 sec. ON

8 sec. OFF

14 sec. OFF

20 sec. OFF

26 sec. OFF

50% (MEDIUM)

Approx. 50%

18 sec. ON

30% (MEDIUM

LOW)

Approx. 30%

12 sec. ON

10% (LOW)

Approx. 10%

6 sec. ON

6

R-90GCK

AUTOMATIC COOKING

Automatic cooking will automatically compute the oven

temperature, microwave power and cooking time. And

the oven will cook according to the special cooking

sequence.

temperature, microwave power and cooking time. And

the oven will cook according to the special cooking

sequence.

POWER CONTROL FOR MANUAL COOKING

Following table shows the power control for manual

cooking.

cooking.

FIRE SENSING FEATURE (MICROWAVE MODE)

This model incorporates a sensing feature which will stop

the oven's operation if there is a fire in the oven cavity

during microwave cooking. This fire sensing feature will

operate when the microwave power level is set to 80% or

more. This is accomplished by the LSI repeatedly meas-

uring the voltage across the temperature measurement

circuit (thermistor) during it's 32-seconds time base com-

paring the obtained voltage measurements. If the most

recent voltage measured is 300 mV greater than the

previous voltage measured, the LSI judges it as a fire in the

oven cavity and switches off the relays to the power

transformer, fan motor and convection motor. The LSI also

stops counting down and closes the damper door so that

no fresh air will enter the oven cavity. Please refer to the

following section for a more detailed description.

the oven's operation if there is a fire in the oven cavity

during microwave cooking. This fire sensing feature will

operate when the microwave power level is set to 80% or

more. This is accomplished by the LSI repeatedly meas-

uring the voltage across the temperature measurement

circuit (thermistor) during it's 32-seconds time base com-

paring the obtained voltage measurements. If the most

recent voltage measured is 300 mV greater than the

previous voltage measured, the LSI judges it as a fire in the

oven cavity and switches off the relays to the power

transformer, fan motor and convection motor. The LSI also

stops counting down and closes the damper door so that

no fresh air will enter the oven cavity. Please refer to the

following section for a more detailed description.

Operation

Please refer to the timing diagrams below.

1. The fire sensing will start after 30 minutes when the

Please refer to the timing diagrams below.

1. The fire sensing will start after 30 minutes when the

oven is started.

2. The thermistor operates within a 32-seconds time base

and it is energized for three (3) seconds and off for 29

seconds. Two (2) seconds after the thermistor is

energized, the voltage across the temperature

measurement circuit is sampled by the LSI and twenty

five (25) seconds after the thermistor is cut off the LSI

turns on the convection fan for three (3) seconds.

seconds. Two (2) seconds after the thermistor is

energized, the voltage across the temperature

measurement circuit is sampled by the LSI and twenty

five (25) seconds after the thermistor is cut off the LSI

turns on the convection fan for three (3) seconds.

3. The above procedure is repeated. If the difference

between the first voltage measured (in step 1) and the

voltage measured when the procedure is repeated

(step 2) is greater than 300 mV the LSI makes the

judgment that there is a fire in the oven cavity and will

switch off the relays to the power transformer, fan

motor and convection motor.

voltage measured when the procedure is repeated

(step 2) is greater than 300 mV the LSI makes the

judgment that there is a fire in the oven cavity and will

switch off the relays to the power transformer, fan

motor and convection motor.

Micro ON

Side heaer

%

-

-

-

70

50

30

10

70

50

30

10

70

50

30

10

70

50

30

10

50

30

10

70

50

30

10

70

50

30

10

70

50

30

10

0

0

0

0

0

0

0

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

220

o

C

220

o

C

200

o

C

220 - 250

o

C

180 - 190

o

C

40 - 160

o

C

200

o

C

220 - 250

o

C

180 - 190

o

C

40 - 160

o

C

Side heaer

%

-

100

30

50

70

90

30

50

70

90

30

50

70

90

30

50

70

90

20

20

20

20

50

70

90

30

50

70

90

30

50

70

90

30

50

70

90

20

20

20

20

100

60

60

60

50

50

50

50

40

40

40

40

30

60

60

50

50

50

50

40

40

40

40

30

Top heaer

%

-

100

30

50

70

90

30

50

70

70

30

50

70

70

30

30

10

10

10

10

10

10

50

70

90

30

50

70

70

30

50

70

70

30

30

10

10

10

10

10

10

100

60

50

50

50

50

40

40

40

40

30

30

30

50

50

50

50

40

40

40

40

30

30

30

70%

-

50%

50%

30%

10%

50%

50%

30%

10%

50%

50%

30%

10%

50%

50%

30%

10%

50%

30%

10%

50%

50%

30%

10%

50%

50%

30%

10%

50%

50%

30%

10%

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Micro

%

10-100

-

70

50

30

10

70

50

30

10

70

50

30

10

70

50

30

10

70

50

30

10

50

30

10

70

50

30

10

70

50

30

10

70

50

30

10

70

50

30

10

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Micro. OFF

Oven

temperature

Powr down

time

Power after powr down time

Manual

MENU

MICROWAVE

GRILL

GRILL

REHAET

CONV.

(Normal)

(Normal)

DUAL1

DUAL2

Air

Balancel

Jet

Jet

Conv.

Conv.

Conv.

Conv.

Conv.

Conv.

Conv.

Conv. or Jet

-

-

-

-

-

50%

-

-

-

-

-

40 - 250

o

C

250

o

C

230

o

C

200 - 220

o

C

40 -190

o

C

250

o

C

230

o

C

200 - 220

o

C

40 - 190

o

C

250

o

C

230

o

C

200 - 220

o

C

40 - 190

o

C

40 min.

60 min.

60 min.

All

30 min.

All

30 min.

All

45 min.

All

45 min.

None

30 min.

30 min.

20 min.

20 min.

30 min.

30 min.

20 min.

20 min.

60 min.

60 min.

30 min.

20 min.

30 min.

20 min.

20 min.

30 min.

30 min.

20 min.

20 min.

60 min.

60 min.

30 min.

20 min.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

50%

30%

30%

30%

-

-

30%

30%

30%

20%

30%

30%

30%

20%

30%

30%

30%

20%

30%

30%

20%

30%

30%

30%

20%

30%

30%

30%

20%

-

-

-

20%

20%

20%

-

-

30%

30%

30%

20%

30%

30%

30%

20%

30%

30%

30%

20%

30%

30%

20%

30%

30%

30%

20%

30%

30%

30%

20%

Top heaer Side heaer

Side heaer

Micro.

Micro. ON

Micro. OFF

Cool oven

(Oven Temperature

less than 59˚C)

(Oven Temperature

less than 59˚C)

After preheating

(Oven Temperature

more than 100˚C)

(Oven Temperature

more than 100˚C)

Warm oven

(Oven Temperature

60˚C - 99˚C)

(Oven Temperature

60˚C - 99˚C)

7

R-90GCK

CONVECTION

MOTOR

THERMISTOR

Sensing

Voltage

ON

OFF

ON

OFF

ON

OFF

0 2 3

28

31

32 (sec.)

64 (sec.)

3 sec.

Sensing the voltage across temperature measurement circuit.

3 sec.

The LSI also stops counting down and closes the

damper door so that no fresh air will enter the oven

cavity.

damper door so that no fresh air will enter the oven

cavity.

4. Once the fire sensor feature has shut the unit down, the

programmed cooking cycle may be resumed by

pressing the "START" pad or the unit may be reset by

pressing the "CLEAR" pad.

pressing the "START" pad or the unit may be reset by

pressing the "CLEAR" pad.

FUNCTION OF IMPORTANT COMPONENTS

DOOR OPEN MECHANISM

The door is opened by pulling the door handle down and

forward, referring to the figure D-1. When the door handle

is pulled down, the latch heads are moved upward. And

then when the door handle is pulled forward, the latch

heads are released from the latch hooks right and left.

Now, the door will open.

forward, referring to the figure D-1. When the door handle

is pulled down, the latch heads are moved upward. And

then when the door handle is pulled forward, the latch

heads are released from the latch hooks right and left.

Now, the door will open.

Figure D-1. Door Open Mechanism

DOOR SENSING SWITCH, SECONDARY INTER-

LOCK SWITCH AND 3RD. LATCH SWITCH

LOCK SWITCH AND 3RD. LATCH SWITCH

1. When the oven door is closed, the contacts (COM-NO)

must be closed.

2. When the oven door is opened, the contacts (COM-

NO) must be opened.

MONITOR SWITCH

1. When the oven door is closed, the contacts (COM-NC)

must be opened.

2. When the oven door is opened, the contacts (COM-

NC) must be closed.

3. If the oven door is opened and the contacts (COM-NO)

of the secondary interlock switch and the relay RY2 fail

to open, the fuse F10A blows simultaneously with

closing the contacts (COM-NC) of the monitor switch .

to open, the fuse F10A blows simultaneously with

closing the contacts (COM-NC) of the monitor switch .

CAUTION: BEFORE REPLACING A FUSE TEST THE

SECONDARY INTERLOCK SWITCH, RELAY

RY2 AND MONITOR SWITCH FOR PROPER

OPERATION. (REFER TO CHAPTER "TEST

PROCEDURE".)

RY2 AND MONITOR SWITCH FOR PROPER

OPERATION. (REFER TO CHAPTER "TEST

PROCEDURE".)

FUSE F10A

1. The fuse F10A blows when the contacts (COM-NO) of

the secondary interlock switch and relay RY2 remain

closed with the oven door open and when the monitor

switch closes.

closed with the oven door open and when the monitor

switch closes.

2. If the wire harness or electrical components are short-

circuited, the fuse F10A blows to prevent an electric

shock of fire hazard.

shock of fire hazard.

HIGH VOLTAGE FUSE

The high voltage fuse blows when the high voltage rectifier

or the magnetron is shorted.

or the magnetron is shorted.

NOISE FILTER

The noise filter prevents the radio frequency interference

that might flow back in the power circuit.

that might flow back in the power circuit.

THERMISTOR

The thermistor is a negative temperature coefficient type.

The temperature in the oven cavity is detected through the

resistance of the thermistor, and then the control unit causes

the heater relay to operate, thus the current to the heating

elements is turned ON/OFF. If the convection cooking or

some cooking modes which use the top / side heating

elements is started and the oven temperature does not rise

above 37.8˚C, the control unit will stop the oven after 10

minutes. In this case, the thermistor may be opened.

The temperature in the oven cavity is detected through the

resistance of the thermistor, and then the control unit causes

the heater relay to operate, thus the current to the heating

elements is turned ON/OFF. If the convection cooking or

some cooking modes which use the top / side heating

elements is started and the oven temperature does not rise

above 37.8˚C, the control unit will stop the oven after 10

minutes. In this case, the thermistor may be opened.

Monitor switch

Latch hook left

Latch

head

head

3rd. latch

switch

switch

Latch hook right

Latch

head

head

Door handle

Secondary

interlock switch

(Monitored latch switch)

interlock switch

(Monitored latch switch)

Door

sensing switch

(Primary interlock

relay control switch)

sensing switch

(Primary interlock

relay control switch)