Read Sharp R-8740 (serv.man9) Service Manual online

R-8740M - 21

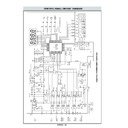

TOUCH CONTROL PANEL ASSEMBLY

OUTLINE OF TOUCH CONTROL PANEL

6) I-2 (Memory Processor)

This is a memory IC, responsible for memory

function.

function.

7) Display Circuit

This is a circuit for driving light emitting diode by I-1

output.

output.

8) Key Input Circuit

This is a circuit for transmitting key input information

to I-1.

to I-1.

9) Relay Driving Circuit

This is a circuit for driving output relay by I-1 output.

10) Door Sensing Switch Circuit

This is a circuit for driving I-1 to detect door opening/

closing.

closing.

11) Buzzer Circuit

The buzzer is responsive to signals from the I-1 to

emitaudible sounds (key touch sound and

completion sound).

emitaudible sounds (key touch sound and

completion sound).

12) Back Light Circuit

A circuit to drive the back light (Light emitting diodes

LD1 - LD4).

LD1 - LD4).

13) Cooking Mode Indicator Circuit

A circuit to drive cooking mode indicator (Light

emitting diodes LD6 - LD9).

emitting diodes LD6 - LD9).

14) Temperature Measurement Circuit : (OVEN

THERMISTOR)

The temperature in the oven cavity is sensed by the

thermistor. The variation of resistance according to

sensed temperature is detected by the temperature

measurement circuit and the result applied to I-1.

The I-1 uses this information to control the relay and

display units.

The temperature in the oven cavity is sensed by the

thermistor. The variation of resistance according to

sensed temperature is detected by the temperature

measurement circuit and the result applied to I-1.

The I-1 uses this information to control the relay and

display units.

The touch control section consists of the following units

as shown in the touch control panel circuit.

as shown in the touch control panel circuit.

(1) Control Unit

(2) Key Unit

(2) Key Unit

The principal functions of these units and the signals

communicated among them are explained below.

communicated among them are explained below.

1. Control Unit

Signal of key touch and oven function control are all

processed by one microcomputer.

processed by one microcomputer.

1) Power Supply Circuit

This circuit changes output voltage at the secondary

side of the low voltage (T1) transformer to voltages

required at each part by full wave rectifying circuit,

constant voltage circuit, etc..

side of the low voltage (T1) transformer to voltages

required at each part by full wave rectifying circuit,

constant voltage circuit, etc..

Symbol

Voltage

Application

VC

-5.0V

I-1

2) ACL Circuit

This is an Auto-clear Circuit, i.e., a reset circuit,

which enables I-1 to be activated from initial state.

which enables I-1 to be activated from initial state.

3) Power SYNC Signal Generating Circuit

This is a circuit for generating power SYNC

(synchronizing) signal by virtue of the secondary

side output of transformer T1.

This signal is used for a basic frequency to time

processing and so on.

(synchronizing) signal by virtue of the secondary

side output of transformer T1.

This signal is used for a basic frequency to time

processing and so on.

4) Clock Circuit

This is a circuit for controlling clock frequency

required for operating I-1.

required for operating I-1.

5) I-1 (Main Processor)

This is a one-chip microcomputer, responsible for

controlling the entire control unit.

controlling the entire control unit.

R-8740M - 22

The key unit is composed of a matrix circuit in which when a key it touched, one of signals P12-P17 generated

by the LSI, is passed through the key and returned to the LSI as one of signals P20-P23.

This model has 10 Memory pads.

When the oven is shipped, Memory pad 1 to 10 are set as follows: Table 1.

by the LSI, is passed through the key and returned to the LSI as one of signals P20-P23.

This model has 10 Memory pads.

When the oven is shipped, Memory pad 1 to 10 are set as follows: Table 1.

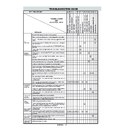

Table 1. Preset memory contents

Memory No.

MENU

WEIGHT

STAGE

MODE

PAUSE

COOKING TIME

REDUCE

FACTOR

1

PIZZA-THIN

350G

1)

70% MW / TG

-

2'30

0.8

2)

TG / BG

5'00

TTL

7'30

2

PIZZA-THIN

450G

1)

70% MW / TG

-

2'40

0.9

2)

TG

1'00

3)

TG / BG

4'30

TTL

8'10

3

PIZZA BAGUETTE

250G

1)

100% MW / TG

-

2'00

0.85

2)

TG

3'00

3)

TG / BG

2'30

TTL

7'30

4

CIABATTA PIZZA

185G

1)

70% MW / TG

-

2'00

0.8

2)

TG / BG

3'30

3)

TG

1'30

TTL

7'00

5

GARLIC BREAD

170G

1)

70% MW / TG

-

1'30

0.9

2)

TG / BG

2'30

3)

30% MW / BG

1'00

TTL

5'00

6

CHEESE BURGER

145G

1)

50% MW / BG

-

3'00

0.9

2)

TG

2'00

TTL

5'00

7

SAUSAGE

250G

1)

TG / BG

YES

5'00

0.9

2)

TG / BG

-

5'00

TTL

10'00

8

SOUP / CASSEROLE

200G

1)

100% MW

-

1'30

0.9

9

DINNER PLATES

480G

1)

100% MW

YES

5'00

0.9

2)

100% MW

5'00

TTL

10'00

0

PIQUANT

300G

1)

10% MW

-

3'00

0.8

PASTRY

2)

10% MW / 200˚C

12'00

TTL

15'00

TG : Top heater. BG : Bottom heater. MW : Microwave

How to set the preset memory contents (For only reference)

When the memory IC (I-2) is exchanged, it is not necessary to set the preset memory contents for SEEG

model. Because the initial memory IC (I-2) has been set them.

model. Because the initial memory IC (I-2) has been set them.

1) To set the preset memory contents for SEEG model.

* You can input for 1 min. from plug in.

PAD

DISPLAY

INDICATOR and LED

PHONE

( PLUG IN )

. 0

LOCK

TIME REDUCE

CONV

MICRO

( within 2 sec. )

CONV

MICRO

( within 2 sec. )

(within 1 min. )

BOTTOM GRILL

C o n t

BTM

MEMORY

b d

KEY UNIT

R-8740M - 23

LSI(IX091DR)

The I/O signal of the LSI(IX091DR) are detailed in the following table.

The I/O signal of the LSI(IX091DR) are detailed in the following table.

Pin No.

Signal

I/O

Description

1-2

VL2-VL1

IN

Power source voltage input terminal.

Standard voltage for LCD.

Standard voltage for LCD.

3-5

AN7-AN5

IN

Terminal to change functions according to the Model.

DC voltage in accordance with the Model in operation is applied to set up its

function.

DC voltage in accordance with the Model in operation is applied to set up its

function.

6

AN4

IN

Temperature measurement input: OVEN THERMISTOR.

By inputting DC voltage corresponding to the temperature detected by the

thermistor, this input is converted into temperature by the A/D converter built

into the LSI.

By inputting DC voltage corresponding to the temperature detected by the

thermistor, this input is converted into temperature by the A/D converter built

into the LSI.

7

AN3

IN

Terminal not used.

8

AN2

IN

Input signal which communicates the door open/close information to LSI.

Door closed; "H" level signal.

Door opened; "L" level signal.

Door closed; "H" level signal.

Door opened; "L" level signal.

9-10

P61-P60

OUT

Timing signal output terminal for temperature measurement(OVEN

THERMISTOR)

"H" level (GND) : Thermistor OPEN timing.

"L" level (-5V) : Temperature measuring timing. (Convection cooking)

THERMISTOR)

"H" level (GND) : Thermistor OPEN timing.

"L" level (-5V) : Temperature measuring timing. (Convection cooking)

11

P57

IN

Terminal not used.

12

P56

OUT

Oven lamp and turntable motor driving signal(Square Waveform : 50Hz).

To turn on and off shut-off relay

(RY1). The square waveform voltage

is delivered to the relay (RY1) driving

circuit .

To turn on and off shut-off relay

(RY1). The square waveform voltage

is delivered to the relay (RY1) driving

circuit .

13

P55

OUT

Terminal not used.

14

P54

OUT

Signal to sound buzzer.

A: key touch sound.

B: Completion sound.

C: When the temperature of the oven

A: key touch sound.

B: Completion sound.

C: When the temperature of the oven

cavity reaches the preset temperature

in the preheating mode.

in the preheating mode.

D: When "SOUND ON" is set with the

SOUND key. When the MEMORY key

is continued to push for more than 5

seconds and the memory setting

condition is set.

is continued to push for more than 5

seconds and the memory setting

condition is set.

15

P53

OUT

Terminal not used.

16

P52

OUT

Fan motor driving signal.

To turn on and off the fan motor relay

RY5. "L" level during cooking, or for 90

seconds after manual cooking or 65

seconds after memory cooking (in case

where the same memory cooking is

operated for more than 10 minutes), or

until the oven cavity has been cooled

after convection or dual cooking.

To turn on and off the fan motor relay

RY5. "L" level during cooking, or for 90

seconds after manual cooking or 65

seconds after memory cooking (in case

where the same memory cooking is

operated for more than 10 minutes), or

until the oven cavity has been cooled

after convection or dual cooking.

17

P51

OUT

Bottom heater driving signal.

To turn on and off the bottom relay

(RY4). "L" level during grill (BOTTOM

HEATER, TOP AND BOTTOM) cooking

or dual (MICRO + BOTTOM) cooking or

convection cooking. "H" level otherwise.

To turn on and off the bottom relay

(RY4). "L" level during grill (BOTTOM

HEATER, TOP AND BOTTOM) cooking

or dual (MICRO + BOTTOM) cooking or

convection cooking. "H" level otherwise.

18

P50

OUT

Convection motor driving signal.

To turn on and off shut-off relay (RY7).

"L" level during CONVECTION; "H" level

otherwise.

To turn on and off shut-off relay (RY7).

"L" level during CONVECTION; "H" level

otherwise.

DESCRIPTION OF LSI

20 msec

During cooking

H

L

A

B

C

H: GND

L

0.12 sec

2.4 sec

1.2 sec

1.2 sec

D

0.08 sec

0.08 sec

0.08 sec

ON

OFF

During cooking, or for 90 sec.

after manual cooking or 65 sec.

after memory cooking, or until

the oven cavity has been cooled

after convection or dual cooking.

after manual cooking or 65 sec.

after memory cooking, or until

the oven cavity has been cooled

after convection or dual cooking.

H : GND

L : -5V

ON

OFF

During

cooking

L

GND

H.

(Convection)

ON

OFF

During

cooking

L

GND

H.

(Grill, dual or convection)

R-8740M - 24

Pin No.

Signal

I/O

Description

ON/OFF time ratio in Micro

cooking

(a. 32second time base)

(a. 32second time base)

ON/OFF time ratio in Micro

cooking

(a. 48second time base)

cooking

(a. 48second time base)

MICRO

ON

OFF

COOK

100%

100%

32sec.

0sec.

70%

24sec.

8sec.

50%

18sec.

14sec.

30%

12sec.

20sec.

10%

6sec.

26sec.

MICRO

ON

OFF

COOK

100%

100%

48sec.

0sec.

70%

36sec.

12sec.

50%

26sec.

22sec.

30%

16sec.

32sec.

10%

8sec.

40sec.

19

P47

OUT

Grill heater (TOP HEATER) driving signal.

To turn on and off the grill heater relay

(RY3). "L" level during grill (TOP

GRILL, TOP AND BOTTOM) cooking

or dual (MICRO + TOP) cooking or

convection cooking. "H" level

otherwise.

To turn on and off the grill heater relay

(RY3). "L" level during grill (TOP

GRILL, TOP AND BOTTOM) cooking

or dual (MICRO + TOP) cooking or

convection cooking. "H" level

otherwise.

20

P46

OUT

Magnetron high-voltage circuit driving signal.

To turn on and off the cook

relay (RY2). In 100%

POWER operation, the

signals hold "L" level during

microwave cooking and "H"

level while not cooking. In

other cooking modes (70%,

50%, 30%, 10%) the signal

turns to "H" level and "L"

level in repetition according

to the power level.

To turn on and off the cook

relay (RY2). In 100%

POWER operation, the

signals hold "L" level during

microwave cooking and "H"

level while not cooking. In

other cooking modes (70%,

50%, 30%, 10%) the signal

turns to "H" level and "L"

level in repetition according

to the power level.

21

P45

OUT

Memory (I-2) clock output.

22

P44

IN/OUT

Memory (I-2) data input/output.

23

INT1

OUT

Terminal not used.

24

INT0

IN

Signal to synchronized LSI with commercial power source

frequency(50Hz).

This is basic timing for time processing of LSI.

frequency(50Hz).

This is basic timing for time processing of LSI.

25

P41

IN

Terminal not used.

26

P40

IN

Connected to VC.

27

RESET

IN

Auto clear terminal.

Signal is input to reset the LSI to the initial state when power is applied.

Temporarily set to "L" level the moment power is applied, at this time the LSI

is reset. Thereafter set at "H" level.

Signal is input to reset the LSI to the initial state when power is applied.

Temporarily set to "L" level the moment power is applied, at this time the LSI

is reset. Thereafter set at "H" level.

28-29

P71-P70

OUT

Terminal not used.

30

XIN

IN

Internal clock oscillation frequency input setting.

The internal clock frequency is set by inserting the ceramic filter oscillation

circuit with respect to XIN terminal.

The internal clock frequency is set by inserting the ceramic filter oscillation

circuit with respect to XIN terminal.

31

XOUT

OUT

Internal clock oscillation frequency control output.

Output to control oscillation input of XOUT.

Output to control oscillation input of XOUT.

32

VSS

IN

Power source voltage: -5V.

VC voltage of power source circuit input.

VC voltage of power source circuit input.

33-36

P27-P24

OUT

Terminal not used.

37

P23

IN

Signal coming from touch key.

When any one of G4 line keys on key matrix is touched, a corresponding

signal from P17 - P12 will be input into P23. When no key is touched, the

signal is held at "H" level.

When any one of G4 line keys on key matrix is touched, a corresponding

signal from P17 - P12 will be input into P23. When no key is touched, the

signal is held at "H" level.

38

P22

IN

Signal similar to P23.

When any one of G3 line keys on key matrix is touched, a corresponding

signal will be input into P22.

When any one of G3 line keys on key matrix is touched, a corresponding

signal will be input into P22.

39

P21

IN

Signal similar to P23.

When any one of G2 line keys on key matrix is touched, a corresponding

signal will be input into P21.

When any one of G2 line keys on key matrix is touched, a corresponding

signal will be input into P21.

40

P20

IN

Signal similar to P23.

When any one of G1 line keys on key matrix is touched, a corresponding

signal will be input into P20.

When any one of G1 line keys on key matrix is touched, a corresponding

signal will be input into P20.

DESCRIPTION OF LSI

LSI(IX091DR)

The I/O signal of the LSI(IX091DR) are detailed in the following table.

The I/O signal of the LSI(IX091DR) are detailed in the following table.

ON

OFF

During

cooking

L

GND

H.

(Grill,dual or convection)

20 msec

H : GND

L (-5V)