Read Sharp R-757M (serv.man6) Service Manual online

R-757M - 6

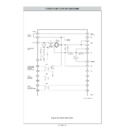

OPERATION SEQUENCE

OFF CONDITION

Closing the door activates all door interlock switches

(monitored latch switch and stop switch).

(monitored latch switch and stop switch).

IMPORTANT:

When the oven door is closed, the monitor switch

contacts COM-NC must be open. When the micro-

wave oven is plugged in a wall outlet (230-240V /

50Hz), the line voltage is supplied to the point A1+A3

in the control unit.

When the oven door is closed, the monitor switch

contacts COM-NC must be open. When the micro-

wave oven is plugged in a wall outlet (230-240V /

50Hz), the line voltage is supplied to the point A1+A3

in the control unit.

Figure O-1 on page

25

1. The display flashes "88:88".

2. To set the any programmes or set the clock, you must

2. To set the any programmes or set the clock, you must

first press the STOP/CLEAR key.

3. " : " appears in the display.

NOTE: When the oven door is opened, the oven lamp

comes on at this time.

MICROWAVE COOKING CONDITION

100P COOKING

Enter a desired cooking time by pressing TIME keys. And

choose the 100P microwave power by pressing MICRO-

WAVE POWER LEVEL key. And then start the oven by

pressing the START key.

Enter a desired cooking time by pressing TIME keys. And

choose the 100P microwave power by pressing MICRO-

WAVE POWER LEVEL key. And then start the oven by

pressing the START key.

Function sequence Figure O-2 on page 25

CONNECTED COMPONENTS

RELAY

Oven lamp, Fan motor, Turntable motor

RY1

Grill heating element

RY2

High voltage transformer

RY3

1. The line voltage is supplied to the primary winding of

the high voltage transformer. The voltage is converted

to about 3.3 volts A.C. output on the filament winding

and high voltage of approximately 2000 volts A.C. on

the secondary winding.

to about 3.3 volts A.C. output on the filament winding

and high voltage of approximately 2000 volts A.C. on

the secondary winding.

2. The filament winding voltage (3.3 volts) heats the

magnetron filament and the high voltage (2000 volts) is

sent to the voltage doubling circuit, where it is doubled

to negative voltage of approximately 4000 volts D.C..

sent to the voltage doubling circuit, where it is doubled

to negative voltage of approximately 4000 volts D.C..

3. The 2450 MHz microwave energy produced in the

magnetron generates a wavelength of 12.24 cm. This

energy is channelled through the waveguide (transport

channel) into the oven cavity, where the food is placed

to be cooked.

energy is channelled through the waveguide (transport

channel) into the oven cavity, where the food is placed

to be cooked.

4. When the cooking time is up, a signal tone is heard and

the relays RY1 + RY3 go back to their home position.

The circuits to the oven lamp, high voltage transformer,

fan motor and turntable motor are cut off.

The circuits to the oven lamp, high voltage transformer,

fan motor and turntable motor are cut off.

5. When the door is opened during a cooking cycle, the

switches come to the following condition.

Condition

During

During

Oven Door

Switch

Contact

Cooking

Open(No cooking)

Monitored latch switch COM-NO

Closed

Opened

Stop switch

COM-NO

Closed

Opened

COM-NO

Closed

Opened

Monitor Switch

COM-NC

Opened

Closed

The circuit to the high voltage transformer, fan motor

and turntable motor are cut off when the monitored

latch switch and stop switch are made open. The oven

lamp remains on even if the oven door is opened after

the cooking cycle has been interrupted, because the

and turntable motor are cut off when the monitored

latch switch and stop switch are made open. The oven

lamp remains on even if the oven door is opened after

the cooking cycle has been interrupted, because the

relay RY1 stays closed. Shown in the display is

remaining time.

remaining time.

6. MONITOR SWITCH CIRCUIT

The monitor switch is mechanically controlled by the

oven door, and monitors the operation of the moni-

tored latch switch.

oven door, and monitors the operation of the moni-

tored latch switch.

6-1. When the oven door is opened during or after the

cycle of a cooking program, the monitored latch

switch and stop switch must open their contacts first.

After, the contacts (COM-NC) of the monitor switch

will close.

switch and stop switch must open their contacts first.

After, the contacts (COM-NC) of the monitor switch

will close.

6-2. When the oven door is closed, the contacts (COM-

NC) of the monitor switch must be opened. After that

the contacts of the monitored latch switch and the

stop switch are closed.

the contacts of the monitored latch switch and the

stop switch are closed.

6-3. If the oven door is opened and the contacts of the

monitored latch switch remain closed, the fuse F2

F8A will blow, because the monitor switch is closed

and a short circuit is made.

F8A will blow, because the monitor switch is closed

and a short circuit is made.

MEDIUM HIGH, MEDIUM, MEDIUM LOW, LOW

COOKING

COOKING

When the microwave oven is preset for variable cooking

power, the line voltage is supplied to the high voltage

transformer intermittently within a 32-second time base

through the relay contact which is coupled with the cur-

rent-limiting relay RY3. The following levels of microwave

power are given.

power, the line voltage is supplied to the high voltage

transformer intermittently within a 32-second time base

through the relay contact which is coupled with the cur-

rent-limiting relay RY3. The following levels of microwave

power are given.

Note:

The On/Off time ratio does not exactly correspond

to the percentage of microwave power, because

approx. 3 seconds are needed for heating up the

magnetron filament.

to the percentage of microwave power, because

approx. 3 seconds are needed for heating up the

magnetron filament.

GRILL COOKING CONDITION

In this condition the food is cooked by the grill heater

energy. Programme the desired cooking time by pressing

TIME keys, and choose the grill mode by pressing GRILL

key once. When the START key is pressed, the following

operations occur:

energy. Programme the desired cooking time by pressing

TIME keys, and choose the grill mode by pressing GRILL

key once. When the START key is pressed, the following

operations occur:

Figure O-3 on page 26

1. The relay RY1 and RY2 are energized.

2. The numbers on the digital readout start the count

down to zero.

3. Then oven lamp, cooling fan motor, turntable motor

and grill heating element are energized.

4. Now, the food is grilled by the grill heating element.

5. Upon completion of the selected cooking time, audible

5. Upon completion of the selected cooking time, audible

signal sounds, and contacts of relays are opened, then

the activated components as items 3 are de-energized.

the activated components as items 3 are de-energized.

100P

32 sec. ON

70P

Approx. 70%=630 Watts

100%=900 Watts

24 sec. ON

8 sec. OFF

14 sec. OFF

20 sec. OFF

26 sec. OFF

50P

Approx. 50%=450 Watts

18 sec. ON

30P

Approx. 30%=270 Watts

12 sec. ON

10P

Approx. 10%=90 Watts

6 sec. ON

R-757M - 7

DOOR OPEN MECHANISM

The door can be opened by pulling the door handle. When

the door handle is pulled, the latch head is moved upward,

and released from the latch hook, now the door can be

opened.

the door handle is pulled, the latch head is moved upward,

and released from the latch hook, now the door can be

opened.

Figure D-1. Door Open Mechanism

Basis cooking time

Reduced power output

Cooking mode

(minutes)

(%)

Microwave (100%)

20

70

Grill

30

50

DUAL (Micro

10%-70%) + Grill

10%-70%) + Grill

30

50 (Grill)

NOTE:

1. If the multiple sequence cooking is carried out in the

1. If the multiple sequence cooking is carried out in the

same mode, the basis cooking time is calculated from

the first.

the first.

2. Even if the cooking is stopped by the STOP/CLEAR

key or opening the door, the basis cooking time is

calculated from the first.

calculated from the first.

3. If the same cooking mode is repeated within 1 minute

and 15 seconds, the basis cooking time is calculated

from the first.

from the first.

4. If the same manu of automatic cooking is repeated

within 1 minute and 15 seconds, the power output of

the microwave or the grill will be reduced to 70% after

20 minutes when the oven is started at first.

the microwave or the grill will be reduced to 70% after

20 minutes when the oven is started at first.

DUAL COOKING CONDITION

In this condition the food is cooked by both microwave

energy and grill heating element energy simultaneously.

Enter the desired cooking time by pressing TIME keys.

And choose the dual grill mode by pressing DUAL GRILL

key. And choose the microwave power level by pressing

DUAL GRILL or MICROWAVE POWER LEVEL key. When

the START key is pressed, the following operations occur:

energy and grill heating element energy simultaneously.

Enter the desired cooking time by pressing TIME keys.

And choose the dual grill mode by pressing DUAL GRILL

key. And choose the microwave power level by pressing

DUAL GRILL or MICROWAVE POWER LEVEL key. When

the START key is pressed, the following operations occur:

Figure O-4 on page 26

1. The relays RY1,RY2 and RY3 are energized.

2. The numbers on the digital read-out start the count

down to zero.

3. Then following components are energized.

High voltage transformer

Grill heating element

Magnetron

Turntable motor

H.V. capacitor

Fan motor

H.V. rectifier

Oven lamp

4. Now, the food is cooked by microwave and grill heating

element energy simultaneously.

5. Upon completion of the selected cooking time, audible

signal sounds, and contacts of relays are opened, then

the activated cpmponents as items 3 are de-energized.

the activated cpmponents as items 3 are de-energized.

6. When cooking in dual mode the microwave power is

limited to 70% (via the I.C.).

EXPRESS DEFROST/ EXPRESS COOK/ MEAL IN

ONE/AUTO CLOCK PROGRAMME

ONE/AUTO CLOCK PROGRAMME

The cooking modes and cooking time are automatically

computed and selected based on the programmes.

computed and selected based on the programmes.

ON/OFF TIME RATIO(DUAL MODE)

In DUAL cooking, the magnetron operates within a 48

second time base. The following table is the ON / OFF time

ratio at each power output of the magnetron.

second time base. The following table is the ON / OFF time

ratio at each power output of the magnetron.

POWER OUTPUT

ON TIME

OFF TIME

100%

48 sec.

0 sec.

70%

36 sec.

12 sec.

50%

26 sec.

22 sec.

30%

16 sec.

32 sec.

10%

8 sec.

40 sec.

POWER OUTPUT REDUCTION

After the same cooking mode is carried out for more than

the basis cooking time, the power output is automatically

reduced by turning the control relays on and off intermit-

tently, as shown in the table below. This is to protect the

oven door against temperature rising.

the basis cooking time, the power output is automatically

reduced by turning the control relays on and off intermit-

tently, as shown in the table below. This is to protect the

oven door against temperature rising.

FUNCTION OF IMPORTANT COMPONENTS

MONITORED LATCH SWITCH AND STOP SWITCH

1. When the oven door is closed, the contacts (COM-NO)

must be closed.

2. When the oven door is opened, the contacts (COM-

NO) must be opened.

MONITOR SWITCH

1. When the oven door is closed, the contacts (COM-NC)

must be opened and contacts (COM-NO) must be

closed.

closed.

2. When the oven door is opened, the contacts (COM-

NC) must closed and contacts (COM-NO) must open.

3. If the oven door is opened and the contacts (COM-NO)

of the monitored latch switch fail to open, the fuse (F8A)

blows simultaneously with closing the contacts (COM-

NC) of the monitor switch.

blows simultaneously with closing the contacts (COM-

NC) of the monitor switch.

Latch Hooks

Stop Switch

Monitor

Switch

Switch

Monitored

Latch

Switch

Latch

Switch

OPERATION SEQUENCE

R-757M - 8

CAUTION: BEFORE REPLACING A BLOWN FUSE F8A,

TEST THE MONITORED LATCH SWITCH

AND MONITOR SWITCH FOR PROPER

OPERATION. (REFER TO CHAPTER “TEST

PROCEDURE”).

AND MONITOR SWITCH FOR PROPER

OPERATION. (REFER TO CHAPTER “TEST

PROCEDURE”).

SPECIAL FUSE 20A 250V

If the wire harness or electrical components are short-

circuited, this fuse blows to prevent an electric shock of

fire hazard.

circuited, this fuse blows to prevent an electric shock of

fire hazard.

FUSE F8A 250V

This fuse also blows when monitored latch switch remains

closed with the oven door open and when the contact

(COM-NC) of monitor switch closes.

1. If the wire harness or electrical components are short-

closed with the oven door open and when the contact

(COM-NC) of monitor switch closes.

1. If the wire harness or electrical components are short-

circuited, this fuse blows to prevent an electric shock

or fire hazard.

or fire hazard.

2. The fuse also blows when the asymmetric rectifier,

H.V. rectifier,.H.V. wire harness, H.V. capacitor,

magnetron or secondary winding of high voltage trans-

former is shorted.

magnetron or secondary winding of high voltage trans-

former is shorted.

THERMAL CUT-OUT 125˚C (MG)

This thermal cut-out protects the magnetron against over-

heat. If the temperature goes up higher than 125˚C be-

cause the fan motor is interrupted or the ventilation open-

ings are blocked, the thermal cut-out will open and line

voltage to the high voltage transformer will cut off and

operation of the magnetron will be stopped. The defec-

tive thermal cut-out must be replaced with a new one.

heat. If the temperature goes up higher than 125˚C be-

cause the fan motor is interrupted or the ventilation open-

ings are blocked, the thermal cut-out will open and line

voltage to the high voltage transformer will cut off and

operation of the magnetron will be stopped. The defec-

tive thermal cut-out must be replaced with a new one.

THERMAL CUT-OUT 145˚C (OVEN)

The thermal cut-out located on the top of the oven cavity

is designed to prevent damaged to the oven if the food in

the oven catch fire due to over heating produced by

improper sitting of cooking time or failure of control unit.

Under normal operation, the oven thermal cut-out remains

closed. However, when abnormally high temperature is

reached within the oven cavity, the oven thermal cut-out

will open at 145˚C, causing the oven to shut down. When

the thermal cut-out cools itself down to the operating

temperature of 115˚C, the contacts of the thermal cut-out

will close again.

is designed to prevent damaged to the oven if the food in

the oven catch fire due to over heating produced by

improper sitting of cooking time or failure of control unit.

Under normal operation, the oven thermal cut-out remains

closed. However, when abnormally high temperature is

reached within the oven cavity, the oven thermal cut-out

will open at 145˚C, causing the oven to shut down. When

the thermal cut-out cools itself down to the operating

temperature of 115˚C, the contacts of the thermal cut-out

will close again.

TURNTABLE MOTOR TTM

The turntable motor rotates the turntable.

FAN MOTOR

The fan motor drives a blade which draws external cool air.

This cool air is directed through the air vanes surrounding

the magnetron and cools the magnetron. This air is chan-

nelled through the oven cavity to remove steam and

vapours given off from heating food. It is then exhausted

through the exhausting air vents of the oven cavity.

This cool air is directed through the air vanes surrounding

the magnetron and cools the magnetron. This air is chan-

nelled through the oven cavity to remove steam and

vapours given off from heating food. It is then exhausted

through the exhausting air vents of the oven cavity.

GRILL HEATING ELEMENT

The grill heating element is provided to brown the food and

is located on the top of the oven cavity.

is located on the top of the oven cavity.

NOISE FILTER

The noise filter prevents radio frequency interference that

might flow back in to the power circuit.

might flow back in to the power circuit.

ASYMMETRIC RECTIFIER

The asymmetric rectifier is solid state device that prevents

current flow in both directions. And it prevents the tem-

perature rise of the high voltage transformer by blowing

the fuse F8A when the high voltage rectifier is shorted.

current flow in both directions. And it prevents the tem-

perature rise of the high voltage transformer by blowing

the fuse F8A when the high voltage rectifier is shorted.

The rated peak reverse voltage of D1 of the asymmetric

rectifier is 6 KV The rated peak reverse voltage of D2 of the

asymmetric rectifier is 1.7 KV. D1 and D2 of the asymmet-

ric rectifier or high voltage rectifier are shorted when the

each peak reverse voltage goes beyond the each rated

peak reverse voltage. (The process of the blowing the fuse

F8A.)

1. The high voltage rectifier is shorted by some fault when

rectifier is 6 KV The rated peak reverse voltage of D2 of the

asymmetric rectifier is 1.7 KV. D1 and D2 of the asymmet-

ric rectifier or high voltage rectifier are shorted when the

each peak reverse voltage goes beyond the each rated

peak reverse voltage. (The process of the blowing the fuse

F8A.)

1. The high voltage rectifier is shorted by some fault when

microwave cooking or dual cooking.

2. The peak reverse voltage of D2 of the rectifier goes

beyond the rated peak reverse voltage 1.7 KV in the

voltage doubler circuit.

voltage doubler circuit.

3. D2 of the rectifier is shorted.

4. The large electric currents flow through the high volt-

4. The large electric currents flow through the high volt-

age winding of the high voltage transformer.

5. The large electric currents beyond 8A flow through the

primary winding of the high voltage transformer.

6. The fuse F8A blows by the large electric currents.

7. The power supplying to the high voltage transformer is

7. The power supplying to the high voltage transformer is

cut off.

D2

D1

ASYMMETRIC

RECTIFIER

RECTIFIER

HIGH VOLTAGE RECTIFIER

OPERATION SEQUENCE