Read Sharp DV-L88 (serv.man6) Service Manual online

DV-L88S/S(H)

DV-L88W/W(A)

DV-L88W/W(A)

10

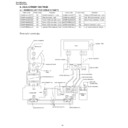

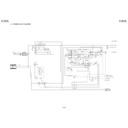

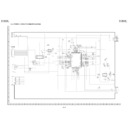

6. ADJUSTMENT METHOD

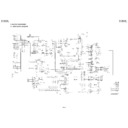

6-1. HARNESS LIST FOR SERVICE PARTS

Drawing for service jigs

Inverter PWB

QCNW-8152GEZZ

QCNW-8151GEZZ

QCNW-8558GEZZ

QCNW-8557GEZZ

CN1901

LCD CTL PWB

OPERATE

PWB

POWER

PWB

MAIN PWB

F

F

C

F

F

C

Panel

CN1900

CN1903

CN1902

CN5001

CN9901

CN802

CN801

CN301

CN6601

CN4402

CN4401

CN1800

CN1801

CN1802

CN1904

9

12

10

9

12

10

Mechanism

QCNW-8562GEZZ

QCNW-8564GEZZ

QCNW-8563GEZZ

QCNW-8565GEZZ

QCNW-8566GEZZ

DET LCD

CLOSE PWB

CLOSE PWB

QCNW-8624GEZZ x4

99GFCKWB90751A

B

to

B

B

to

B

B

to

B

99GFCKWB90751A

99GFCKWB90751A

99GFCKWB90751A

99GFCKWB90751A

99GFCKWB90751A

QCNW-8623GEZZ x2

CN83

CN81

CN82

CN86

CN84

CN85

RF&MOTOR

PWB

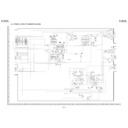

Parts Code

Price Code

Remarks

Parts Code

Price Code

Remarks

QCNW-8557GEZZ

AE

Spindle extension, 13-pin

QCNW-8566GEZZ

AD

Operate PWB extension, 2-pin

QCNW-8558GEZZ

AE

Sled extension, 2-pin

QCNW-8623GEZZ

AZ

Main-RF&Motor extension, 25-pin

QCNW-8562GEZZ

AK

Power-LCD extension, 9-pin

QCNW-8624GEZZ

AX

Main-Power extension, 15-pin

QCNW-8563GEZZ

AK

Power-LCD extension, 10-pin 99GFCKWB90751A

BX

—————

QCNW-8564GEZZ

AK

Power-LCD extension, 12-pin

QCNW-8151GEZZ

AQ

Inverter extension, 6-pin

QCNW-8565GEZZ

AE

Operate PWB extension, 6-pin

QCNW-8152GEZZ

AQ

LCD panel extension, 32-pin

DV-L88S/S(H)

DV-L88W/W(A)

DV-L88W/W(A)

11

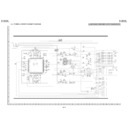

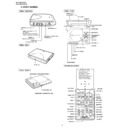

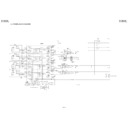

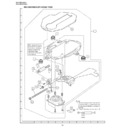

ADJUSTMENT PROCEDURE AND METHOD OF LCD PWB SIDE

Connect the LCD PWB to the jig for shipping adjustment.

Adjustment Item

Adjustment Menu

Adjustment Point

Signal/Setting

Adjustment Contents

1

Free run

R1933

Observe the 5PIN of

No input

Adjust so that the frequency becomes

adjustment

(VR)

TP1900 (HSY) with a

15.63

±

0.1kHz (64.0

µ

S).

frequency counter.

2

Screen center

R1914(VR)

Visual observation of

Monoscope full screen. Adjust the screen so that it is located in the

adjustment

the panel.

(625/25 or 525/30)

center.

HSY

15.63kHz

(64.0

µ

S)

CHECK ITEMS OF LCD PWB SIDE

Adjustment Item

Adjustment Point

Input Signal/Setting

Adjustment Contents

1

Free run check

Check the panel visually by connecting

External input

Check that the horizontal movement of OSD

to the checker.

(625/25)

is 2 mm or less when inputting a signal in

the external input mode with no signal input.

the external input mode with no signal input.

INPUT

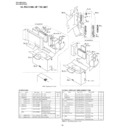

POWER PWB SIDE ADJUSTING PROCEDURE AND METHOD.

Connect the POWER PWB to the jig for shipping adjustment.

Supply the power in the condition that the “ENTER” and “STILL” keys are pressed at the same time and move to the special

mode (SP MODE).

After that, get the initialize set by pressing the “PLAY” key. After setting, turn off the power once.

Supply the power again in the condition that the “ENTER” and “STILL” keys are pressed at the same time and after moving

to the special mode (SP MODE), get the adjustment mode by pressing “INPUT/DVD” key.

Supply the power in the condition that the “ENTER” and “STILL” keys are pressed at the same time and move to the special

mode (SP MODE).

After that, get the initialize set by pressing the “PLAY” key. After setting, turn off the power once.

Supply the power again in the condition that the “ENTER” and “STILL” keys are pressed at the same time and after moving

to the special mode (SP MODE), get the adjustment mode by pressing “INPUT/DVD” key.

Each operation in the adjustment mode changes as follows:

(1) Switch the adjustment block with the "VOLUME+" key input.

(2) Perform paging of each adjustment block with the "RETURN" key.

(3) Switch each adjustment item with the "VOLUME–" key input.

(4) Change each adjustment value with the left or right cursor key.

TV1

TV2

TV3

TV1

OPT

BAT

GAM0

TV1 adjustment

TV2 adjustment

TV3 adjustment

SBRIGHT

GPOS

CONT

WB-R

WB-B

SCOLOR

STINT

COM

OSDH

BBRIGHT

GAIN

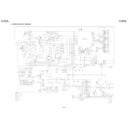

[Caution] Do the image plane center adjustment of

2

after you surely do free run adjustment of

1

.

Image plane center deviates when adjustment is done in the reverse order.

DV-L88S/S(H)

DV-L88W/W(A)

DV-L88W/W(A)

12

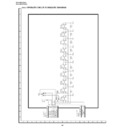

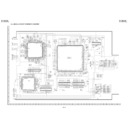

Adjustment Item

Adjustment Menu

Adjustment Point

Signal/Setting

Adjustment Contents

1

Gamma setting

Check that the gamma function of the body is

check

on "level 2".

2

Contrast check

CONT

Check that CONT set value is "AB".

3

RGB amplitude

GAIN

Connect the synchroscope Black-and-white Adjust the Vpp(SYNC-SYNC) of VG to

adjustment

to 2PIN (VG) of TP1900.

10STEP

4.0

±

0.1V.

4

Gamma 0 set

GAM0

The set value of GAM0 is changed from "50" to

value change

"56".

5

Sub-bright

SBRIGHT

Connect the synchroscope Black-and-white Adjust the 10% white part(SYNC-white 10%) to

adjustment

to 2PIN (VG) of TP1900.

10STEP

1.0

±

0.05V.

6

Common

GPOS

Connect the synchroscope Black-and-white Adjust the common amplitude to 8.0

±

0.1V.

amplitude

to 1PIN (COM) of TP1900. 10STEP

adjustment

7

Contrast

CONT

Connect the synchroscope Black-and-white Adjust the 100% white part(SYNC-white100%)

adjustment

to 2PIN (VG) of TP1900.

10STEP

to 3.8

±

0.1V.

8

White balance

WB-R(Red)

Connect the synchroscope Black-and-white Adjust the white balance (red) so that black level

adjustment

to 2PIN (VG) and 3PIN

10STEP

the equal of green and red output become equal.

(Red)

(VR) of TP1900.

*Adjust the 30% white.

9

White balance

WB-B(Blue)

Connect the synchroscope Black-and-white Adjust the white balance (blue) so that black level

adjustment

to 2PIN (VG) and 4PIN

10STEP

the equal of green and blue output become

(Blue)

(VB) of TP1900.

equal.

*Adjust the 30% white.

*Adjust the 30% white.

0

Burst clear

STINT

Connect the synchroscope MOD10STEP

Adjusted so that the side muscle of the colour

adjustment

to 4PIN (VB) of TP1900.

signal may become the smallest with seeing

liquid crystal image plane.

liquid crystal image plane.

[Another method] [Another method]

100% colour bar Adjusted so that every horizontal term space

100% colour bar Adjusted so that every horizontal term space

may become the level which the swing level of

yellow of the colour bar signal is the same as.

yellow of the colour bar signal is the same as.

8.0V

±

0.1

4.0V

±

0.1

3.8V

±

0.1

1.0V

±

0.05

Input

G

DV-L88S/S(H)

DV-L88W/W(A)

DV-L88W/W(A)

13

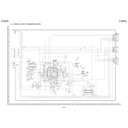

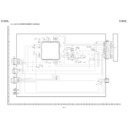

Adjustment Item

Adjustment Menu

Adjustment Point

Signal/Setting

Adjustment Contents

q

Sub colour

SCOLOR

Connect the synchroscope 100% colour bar Adjust the yellow amplitude of the colour bar

adjustment

to 4PIN (VB) of TP1900.

signal (white level to yellow peak level) to

2.5

2.5

±

0.1Vpp.

w

Confrontation

COM

Specified adjustment jig

No input state

When using the specified adjustment jig

bias adjustment

(illuminometer) or visual

Brightness: Center Connect the output of jig to the oscilloscope

observation

Perform it in a

and adjust the waveform to the minimum

combination of

point.

PWB and the

At this time, perform the adjustment several

liquid crystal

times to fix the optimal point because the

panel which will measuring value hardly changes around the

be supplied as

be supplied as

optimal point.

products finally.

In case of visual adjustment Stand or tilt the

panel as shown in the figure and check by

shaking your head and seeing whether stripes

appear.

If the adjustment is improper, you will see

stripes in the longitudinal direction.

Perform the adjustment so that they

do not appear.

panel as shown in the figure and check by

shaking your head and seeing whether stripes

appear.

If the adjustment is improper, you will see

stripes in the longitudinal direction.

Perform the adjustment so that they

do not appear.

[Another method] [Another method]

Flicker signal

Flicker signal

Externally input the signal shown left and

generator

adjust so that the cross bars become minimum

“Example:

by visually checking the screen.

BP1018 made

by JFC”

by JFC”

e

OSD position

OSDH

OSD character

The position of the adjustment value on the

adjustment

visual observation

right end of the OSD character is adjusted to

15mm

±

2mm from the right end of the image

plane.

r

Lighting control

BBRIGHT

Check that the BBRIGHT is “76”.

standard check

(Type drawing)

Optimal point

Adjust within the above

range to fix the optimal point

range to fix the optimal point

Direction of stripe

15mm

2.5V

±

0.1

White

Yellow