Read Sharp XL-HP600 (serv.man10) Service Manual online

XL-HP600E

– 12 –

CD ERROR CODE DESCRIPTION

Error

Explanation

01

When Pickup set inner position, inner switch

cannot detect 'ON' level for 10 secs.

cannot detect 'ON' level for 10 secs.

10*

Cam error. Can't detect cam switch when cam is

moving.

moving.

11*

When it detect cam operation error during initialize

process.

process.

20

Tray error. Can't detect tray switch when tray is

moving.

moving.

21

When it detect tray operation error during initialize

process.

process.

31

When it change to CD function, DSP cannot read

initial data.

initial data.

Test Stage

Frequency

Frequency

Display

Setting/

Adjusting

Parts

Instrument

Connection

CD SECTION

•••••

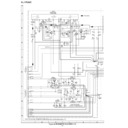

AM IF/RF

Signal generator: 400 Hz, 30%, AM modulated

*1. Input: Antenna

Output: TP302

*2. Input: Antenna

Output: TP301

TUNER SECTION

fL: Low-range frequency

fH: High-range frequency

fH: High-range frequency

AM IF

450 kHz

1,620 kHz

T351

*1

AM Band

—

522 kHz

(fL): T306

*2

Coverage

1.1

±

0.1 V

AM Tracking 990 kHz

990 kHz

(fL): T303

*1

Figure 12-2 ADJUSTMENT POINTS

Items adjusted automatically

(1) Offset adjustment (The offset voltage between the head

amplifier output and the VREF reference voltage is

compensated inside the IC.)

compensated inside the IC.)

* Focus offset adjustment

* Tracking offset adjustment

* Tracking offset adjustment

(2) Tracking balance adjustment

(3) Gain adjustment (The gain is compensated inside the IC

so that the loop gain at the gain crossover frequency will

be 0 dB.)

be 0 dB.)

* Focus gain adjustment

* Tracking gain adjustment

* Tracking gain adjustment

• Adjustment

Since this CD system incorporates the following automatic

adjustment functions, readjustment is not needed when

replacing the pickup. Therefore, different PWBs and pickups

can be combined freely.

Each time a disc is changed, these adjustments are

performed automatically. Therefore, playback of each disc

can be performed under optimum conditions.

adjustment functions, readjustment is not needed when

replacing the pickup. Therefore, different PWBs and pickups

can be combined freely.

Each time a disc is changed, these adjustments are

performed automatically. Therefore, playback of each disc

can be performed under optimum conditions.

* 'CHECKING'

If Error is detected, 'CHECKING' will be displayed instead of

'ER-CD**'. 'ER-CD**' display will only be displayed when error

had been detected for the 5th times.

If Error is detected, 'CHECKING' will be displayed instead of

'ER-CD**'. 'ER-CD**' display will only be displayed when error

had been detected for the 5th times.

• FM IF

Notes:

1. Description of the "FM IF Adjustment" is not carried on this

Notes:

1. Description of the "FM IF Adjustment" is not carried on this

Manual. It is because the IF coil in the FM front end section

has been best adjusted in the factory so that its further

adjustment is not needed at the field. When replacing the

FM front end assembly, no adjustment is needed either.

has been best adjusted in the factory so that its further

adjustment is not needed at the field. When replacing the

FM front end assembly, no adjustment is needed either.

2. The parts in the FM front end section are prepared in a

complete unit, so you can't obtain each part individually.

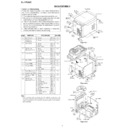

ADJUSTMENT

MECHANISM SECTION

•••••

Driving Force Check

Torque Meter

Specified Value

Play: TW-2111

Over 80 g

•

Torque Check

Torque Meter

Play: TW-2111

30 to 80 g.cm

Fast forward: TW-2231

70 to 180 g.cm

Rewind: TW-2231

70 to 180 g.cm

Specified Value

Specified

Value

Adjusting

Point

Instrument

Connection

Test Tape

Normal

MTT-111

Variable

3,000

±

30 Hz

Speaker

speed

Resistor in

Terminal

motor.

(Load

resistance:

6 ohms)

resistance:

6 ohms)

•••••

Tape Speed

Figure 12-1

TAPE MECHANISM

Tape

Motor

Motor

Variable Resistor in motor

R336

R357

AM

LOOP

ANTENNA

IC302

T351

IC303

L354

T303

T306

CNP302

SO301

FE301

MAIN PWB-A1

TP302

TP301

AM TRACKING fL

AM BAND

COVERAGE fL

COVERAGE fL

AM IF

ANTENNA

TERMINAL

TERMINAL

– 13 –

XL-HP600E

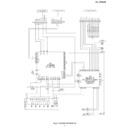

TEST MODE

•

Setting the test mode

Any one of test mode can be set by pressing several keys as follows.

<X-BASS> + <CD> + <ON/STAND-BY> TEST: CD operation test.

<X-BASS> + <CD> + <ON/STAND-BY> TEST: CD operation test.

Function: -CD test mode.

-Enter test 4 mode.

C D T E S T

OPEN/CLOSE operation is using manual.

<<

>>, <<

>> buttons make pick's slide possible.

Do TOC IL. Do normal play.

When these following key is input

into PLAY key, track number can

be appoint directly.

When these following key is input

into PLAY key, track number can

be appoint directly.

<<PLAY>> key input.

<<MEMORY>> key input.

<<

1>> key: Track 4

<<

2>> key: Track 9

<<

3>> key: Track 15

<<STOP>> key input.

STOP

Laser ON.

<<MEMORY>> key input.

Tracking OFF play at that

specific point.

specific point.

<<MEMORY>> key input.

Tracking ON play from

that specific point.

that specific point.

<<STOP>> key input.

STOP

IL isn't done

VOL — Last memory

BAL — CENTER

P.GEQ — FLAT

X-BASS — OFF

BAL — CENTER

P.GEQ — FLAT

X-BASS — OFF

To cancel : Power OFF

Sliding the PICKUP with

<<

<<

>>, <<

>> button

must only be in STOP mode.

<<MEMORY>>

key input.

key input.

Adjustment result

automatically will

display as below.

for each 2 sec :

a) "FOFF_XX"

b) "TOFF_XX"

c) "TBAL_XX"

d) "TGAN_XX"

f) "FGAN_XX"

g) "RFLS_XX"

automatically will

display as below.

for each 2 sec :

a) "FOFF_XX"

b) "TOFF_XX"

c) "TBAL_XX"

d) "TGAN_XX"

f) "FGAN_XX"

g) "RFLS_XX"

explanation:

a) Focus off set

a) Focus off set

= "FOFF_XX"

b) Tracking off set

= "TOFF_XX"

c) Tracking balance

= "TBAL_XX"

d) Tracking Gain

= "TGAN_XX"

f)

Focus Gain

= "FGAN_XX"

g) RF level shift

= "RFLS_XX"

Adjustment result automatically will

display as below for each 2 sec :

a) "FOFF_XX"

b) "TOFF_XX"

c) "TBAL_XX"

d) "TGAN_XX"

f) "FGAN_XX"

g) "RFLS_XX"

display as below for each 2 sec :

a) "FOFF_XX"

b) "TOFF_XX"

c) "TBAL_XX"

d) "TGAN_XX"

f) "FGAN_XX"

g) "RFLS_XX"

<<MEMORY>> key input.

XL-HP600E

– 14 –

Standard Specification of Stereo System Error Message Display Contents

Error Contents

DISPLAY

Notes

CD

Pickup Mechanism Error.

'ER-CD**'

01: PU-IN SW Detection NG.

CD Changer Mechanism Error.

'ER-CD**'

10: Changer Error.

(*)

11: Initial Error.

CD DSP Communication Error

'ER-CD**'

31: DSP COMMUNICATION ERROR

Focus Not Match.

'NO DISC'

TUN

PLL Unlock.

FM

87.50

MHz

PLL Unlock.

(*) CHECKING:

If CD changer mechanism error is detected, 'CHECKING' will be display instead of 'ER-CD**' display 'ER-CD**' will only be display

when CD changer mechanism error had been detected for the 5 th times.

If CD changer mechanism error is detected, 'CHECKING' will be display instead of 'ER-CD**' display 'ER-CD**' will only be display

when CD changer mechanism error had been detected for the 5 th times.

Speaker abnormal detection and +B PROTECTION display

In case speaker abnormal detection or +B PROTECTION had occurred, it can be check by pressing 'POWER', 'VIDEO' and 'X-

BASS' key twice. Display will show "S** B**". S is referring to speaker abnormal detection and B is referring to +B PROTECTION.

** is in hex valve.

In case speaker abnormal detection or +B PROTECTION had occurred, it can be check by pressing 'POWER', 'VIDEO' and 'X-

BASS' key twice. Display will show "S** B**". S is referring to speaker abnormal detection and B is referring to +B PROTECTION.

** is in hex valve.

+B PROTECTION is condition when irregular process occur on power supply line.

Before transporting the unit

The following process need to be taken after set tapering/parts replacement.

1. Press the ON/STAND-BY button to enter stand-by mode.

2. While pressing down the

The following process need to be taken after set tapering/parts replacement.

1. Press the ON/STAND-BY button to enter stand-by mode.

2. While pressing down the

button and the X-BASS/DEMO button, press the ON/STAND-BY button until "CLEAR AL"appears.

3. While pressing down the

/

button and the X-BASS/DEMO button, press the ON/STAND-BY button until "WAIT

→

FINISHED" appears.

4. Unplug the AC cord and the unit is ready for transporting.

4. Unplug the AC cord and the unit is ready for transporting.