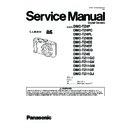

Read Panasonic DMC-TZ4P / DMC-TZ4PC / DMC-TZ4PL / DMC-TZ4EB / DMC-TZ4EE / DMC-TZ4EF / DMC-TZ4EG / DMC-TZ4E / DMC-TZ11GC / DMC-TZ11GK / DMC-TZ11GN / DMC-TZ11GT / DMC-TZ11GJ Service Manual online

DMC-TZ4PL

DMC-TZ4EB

DMC-TZ4EE

DMC-TZ4EF

DMC-TZ4EG

DMC-TZ4E

DMC-TZ11GC

DMC-TZ11GK

DMC-TZ11GN

DMC-TZ11GT

DMC-TZ11GJ

(S)....................Silver Type

(K)....................Black Type (except GT)

1.2. Leakage Current Cold Check ---------------------------3

1.3. Leakage Current Hot Check (See Figure 1)---------3

1.4. How to Discharge the Capacitor on Flash

2.4. How to Replace the Lithium Battery -------------------7

3.2. General Description About Lead Free Solder

5 Location of Controls and Components------------------ 14

6 Service Mode ----------------------------------------------------- 16

7.2. When Replacing the Main PCB ---------------------- 19

7.3. Service Position ------------------------------------------ 19

8.2. PCB Location---------------------------------------------- 21

8.3. Disassembly Procedure -------------------------------- 22

8.4. Disassembly Procedure for the Lens --------------- 27

8.5. Assembly Procedure for Lens ------------------------ 30

8.6. Removal of the CCD Unit ------------------------------ 34

8.7. Removal of the Zoom Motor Unit -------------------- 35

8.8. Removal of the Focus Motor Unit -------------------- 35

8.9. The Applyment of Grease Method ------------------- 36

which are important for safety. These parts are marked by

tial that these critical parts should be replaced with manu-

facturer’s specified parts to prevent X-RADIATION, shock

fire, or other hazards. Do not modify the original design

without permission of manufacturer.

from the AC power line. Use a transformer of adequate

power rating as this protects the technician from acci-

dents resulting in personal injury from electrical shocks. It

will also protect AC Adaptor from being damaged by acci-

dental shorting that may occur during servicing.

overheated or damaged by the short circuit.

properly installed.

shock hazards.

lic cabinet part on the equipment such as screwheads,

connectors, control shafts, etc. When the exposed metal-

lic part has a return path to the chassis, the reading

should be between 1M

(See Figure 1)

and a good earth ground, as shown in Figure 1.

lent) may be used to make the hot checks, leakage cur-

rent must not exceed 1/2 mA. In case a measurement is

outside of the limits specified, there is a possibility of a

shock hazard, and the equipment should be repaired and

rechecked before it is returned to the customer.

2. Be careful of the high voltage circuit on FLASH PCB when servicing.

2. Put the insulation tube onto the lead part of Resistor (ERG5SJ102:1k

4. After discharging confirm that the capacitor voltage is lower than 10V using a voltmeter.