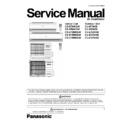

Read Panasonic CS-E7NKDW / CS-E9NKDW / CS-E12NKDW / CS-E15NKDW / CS-E18NKDW / CU-E7NKD / CU-E9NKD / CU-E12NKD / CU-E15NKD / CU-E18NKD Service Manual online

CS-E9NKDW

CS-E12NKDW

CS-E15NKDW

CS-E18NKDW

CU-E9NKD

CU-E12NKD

CU-E15NKD

CU-E18NKD

U-3E18JBE, U-4E23JBE, Order No. PHAAM1004141C2 and Model No. U-2E15GBE, Order No. MAC0704001A2.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service

or repair the product or products dealt with in this service information by anyone else could result in serious injury or death.

CU-E15NKD ...............................................24

CU-E15NKD ...............................................26

of Dry Mode)...............................................52

Operation....................................................58

Connection).......................................................62

Operation................................................... 66

Operation................................................... 67

CS-E15NK ............................................... 104

Procedure ................................................ 112

List .................................................................. 136

will cause harm or damage, and the seriousness is classified by the following indications.

future reference.

water leakage, electrical shock or fire.

fire or electrical shock.

the set will drop and cause injury.

outlet must be used. If electrical circuit capacity is not enough or defect found in electrical work, it will cause electrical shock or fire.

Otherwise, it may cause electrical shock and fire in case equipment breakdown or insulation breakdown.

10. Do not use joint cable for indoor/outdoor connection cable. Use the specified indoor/outdoor connection cable, refer to installation instruction

CONNECT THE CABLE TO THE INDOOR UNIT and connect tightly for indoor/outdoor connection. Clamp the cable so that no external force

will be acted on the terminal. If connection or fixing is not perfect, it will cause heat up or fire at the connection.

11. Wire routing must be properly arranged so that control board cover is fixed properly. If control board cover is not fixed perfectly, it will cause

heat-up or fire at the connection point of terminal, fire or electrical shock.

cycle (piping). (Mixing of air etc. will cause abnormal high pressure in refrigeration cycle and result in explosion, injury etc.).

outdoor unit and cross over the handrail and causing accident.

14. This equipment must be properly earthed. Earth line must not be connected to gas pipe, water pipe, earth of lightning rod and

telephone. Otherwise, it may cause electric shock in case equipment breakdown or insulation breakdown.

other electrical appliances. Poor contact, poor insulation or over current will cause electrical shock or fire.

may break and cause refrigerant gas leakage.

abnormally high pressure in the refrigeration cycle (piping), and possibly result in explosion and injury. Use only R410A materials.

Thickness of copper pipes used with R410A must be more than 0.8mm. Never use copper pipes thinner than 0.8mm.

It is desirable that the amount of residual oil is less than 40 mg/10m.

and valves at opened condition will cause suck-in of air, abnormal high pressure in refrigeration cycle and result in explosion, injury etc).

20. During pump down operation, stop the compressor before remove the refrigeration piping. (Removal of refrigeration piping while compressor is

operating and valves are opened condition will cause suck-in of air, abnormal high pressure in refrigeration cycle and result in explosion,

injury etc.)

21. After completion of installation or service, confirm there is no leakage or refrigerant gas. It may generate toxic gas when the refrigerant

contacts with fire.

unit, it may cause fire.

the furniture.

may break and cause refrigerant gas leakage.

4. Do not touch outdoor unit air inlet and aluminium fin. It may cause injury.

a high temperature solder iron. In case of the soldering iron with temperature control, please set it to 700 ± 20°F (370 ± 10°C).

Pb free solder will tend to splash when heated too high (about 1100°F / 600°C).

7. Power supply connection to the air conditioner. Connect the power supply cord of the air conditioner to the mains using one of the following

methods.

Power supply point shall be the place where there is ease for access for the power disconnection in case of emergency. In some countries,

permanent connection of this room air conditioner to the power supply is prohibited.

i. Power supply connection to the receptacle using a power plug. Use an approved 15/16A (3/4~1.75HP), 16A (2.0HP), 20A (2.5HP) or

25A (3.0HP) power plug with earth pin for the connection to the socket.

ii. Power supply connection to a circuit breaker for the permanent connection. Use an approved 16A (3/4~2.0HP), 20A (2.5HP) or

25A (3.0HP) circuit breaker for the permanent connection. It must be a double pole switch with a minimum 3.0 mm contact gap.

8. Do not release refrigerant during piping work for installation, servicing, reinstallation and during repairing a refrigerant parts.

Take care of the liquid refrigerant, it may cause frostbite.

If you are required to handle sharp parts during installation or servicing, please wear hand glove.

Sharp parts may cause injury.